Energy-saving submerged combustion gasifier

A technology of submerged combustion and gasifier, which is applied in the field of submerged combustion gasifier for low-temperature liquid gasification, energy-saving submerged combustion gasifier, and can solve the problem of high cost, high material selection requirements, submerged combustion gasifier Large footprint and other issues, to achieve the effect of reducing material selection requirements, improving heat transfer coefficient, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

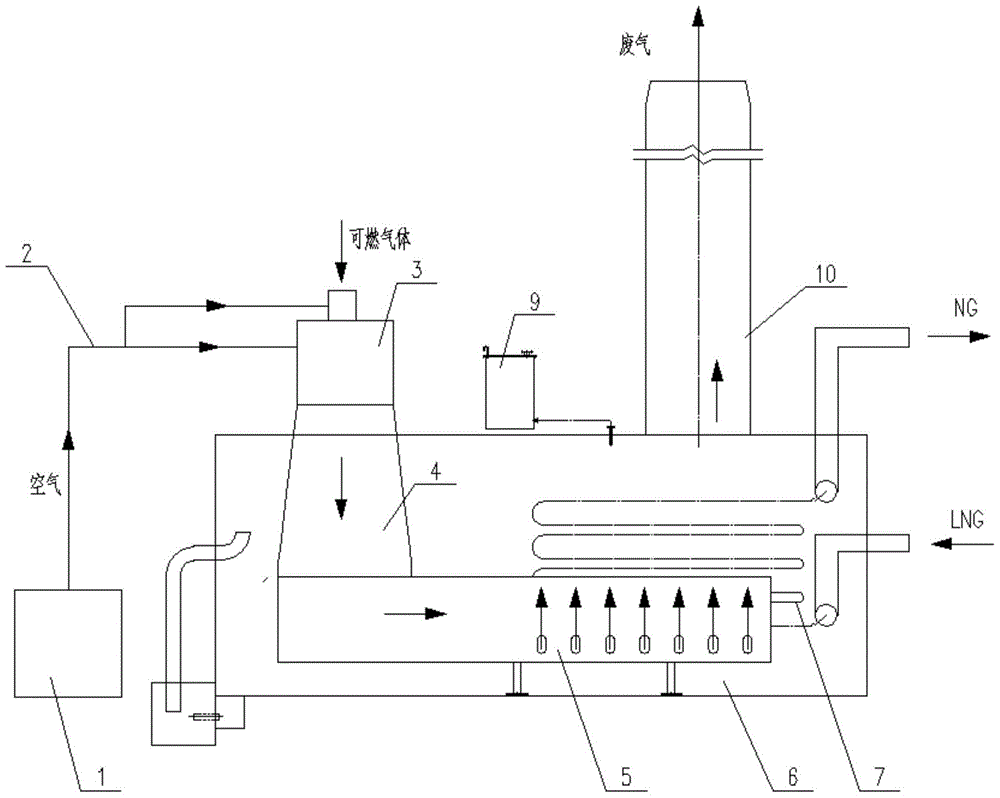

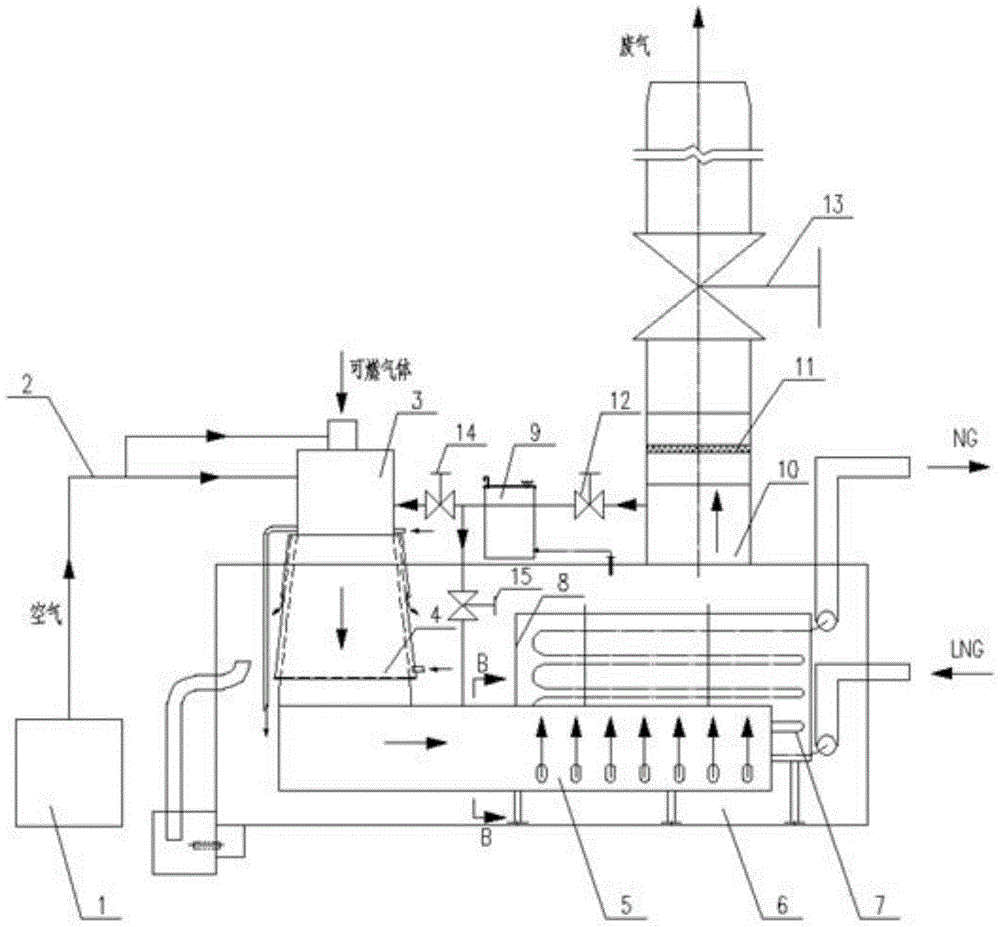

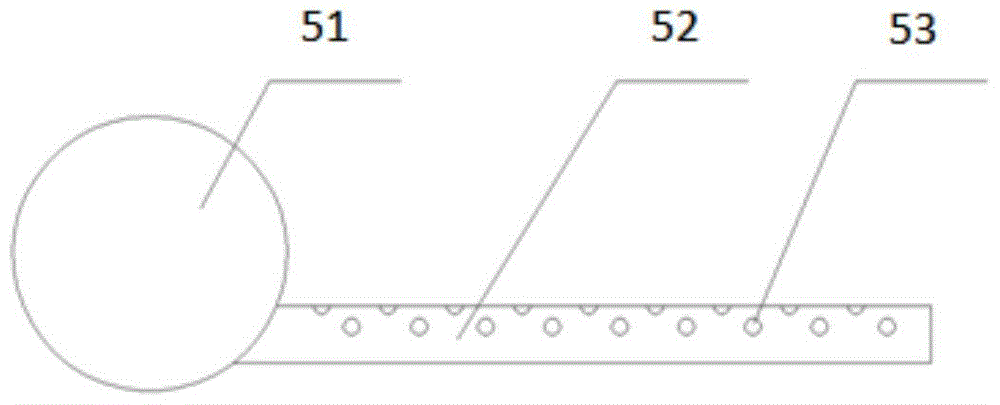

[0029] Such as figure 2 , 3As shown in and 4, an energy-saving submerged combustion gasifier includes a blower 1, an air duct 2, a burner 3, a combustion chamber 4, a flue gas distributor 5, a water tank 6, a heat exchange tube bundle 7, and a weir flow box 8, lye tank 9, chimney 10, gas-liquid separator 11, chimney regulating valve 13; described blower 1 links to each other with the air inlet of burner 3 through air duct 2, and the outlet of described burner 3 is located at The combustion chamber 4 on one side of the water tank 6 is connected, and the air in the burner 3 is fully mixed with the combustible gas entering from the gas inlet of the burner 3, and enters the combustion chamber 4 after ignition to generate high-temperature flue gas; The periphery of the combustion chamber 4 is provided with a water jacket 43, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com