Protector for inner thread in petroleum steel pipe and its making process

A technology of petroleum steel pipe and internal thread, which is applied in the field of petroleum steel pipe internal thread protector and its preparation, can solve the problems of weakening the impact resistance of the protector, poor impact resistance of the plastic layer, and failure to achieve the protection effect, and achieves low price, anti-corrosion Good impact performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

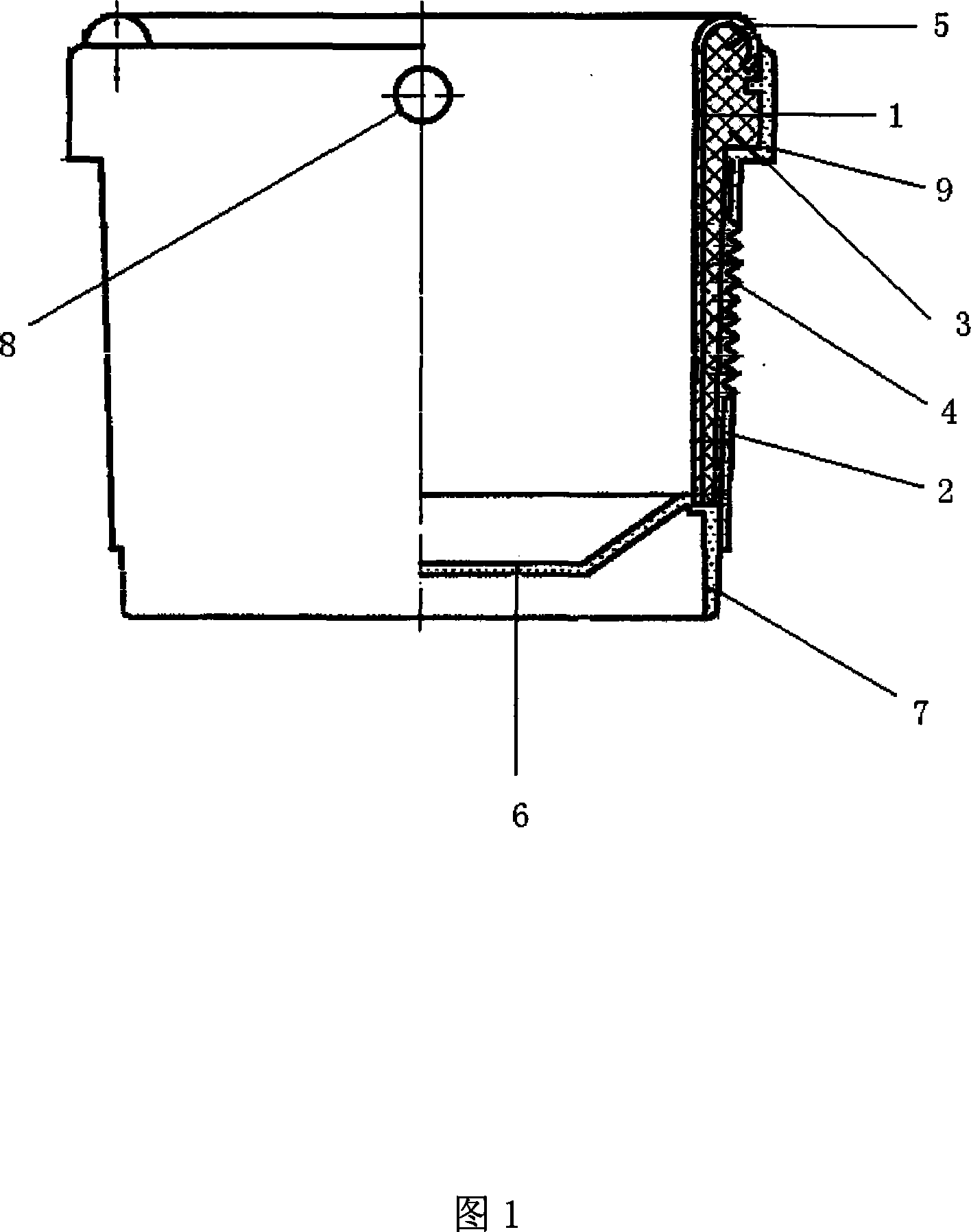

[0031] Figure 1 shows a front view of the present invention with a half section view. It can be seen from the figure that the oil steel pipe internal thread protector of this embodiment includes an annular rigid frame 1 and a plastic outer layer 2 coated on the outside of the frame, and a core layer is arranged between the rigid frame 1 and the plastic outer layer 2 3. The core layer 3 described in this embodiment is a plastic layer made of recycled plastic injection-molded on the outer surface of the rigid frame 1 , and the inner and outer surfaces of the core layer 3 are closely combined with the rigid frame 1 and the plastic outer layer 2 respectively. The outer surface of the plastic outer layer 2 is provided with threads 4 . The top of the rigid framework 1 rolls outwards to form an annular eaves 5, the upper end of the plastic outer layer 2 protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com