Device for horizontally utilizing biomass fuel to continuously produce combustible gases

A biomass fuel, horizontal technology, used in biofuels, special forms of dry distillation, petroleum industry and other directions, can solve the problems of insufficient combustion, inconvenient promotion, air pollution, etc., and achieve simple structure, small environmental impact, and sufficient combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

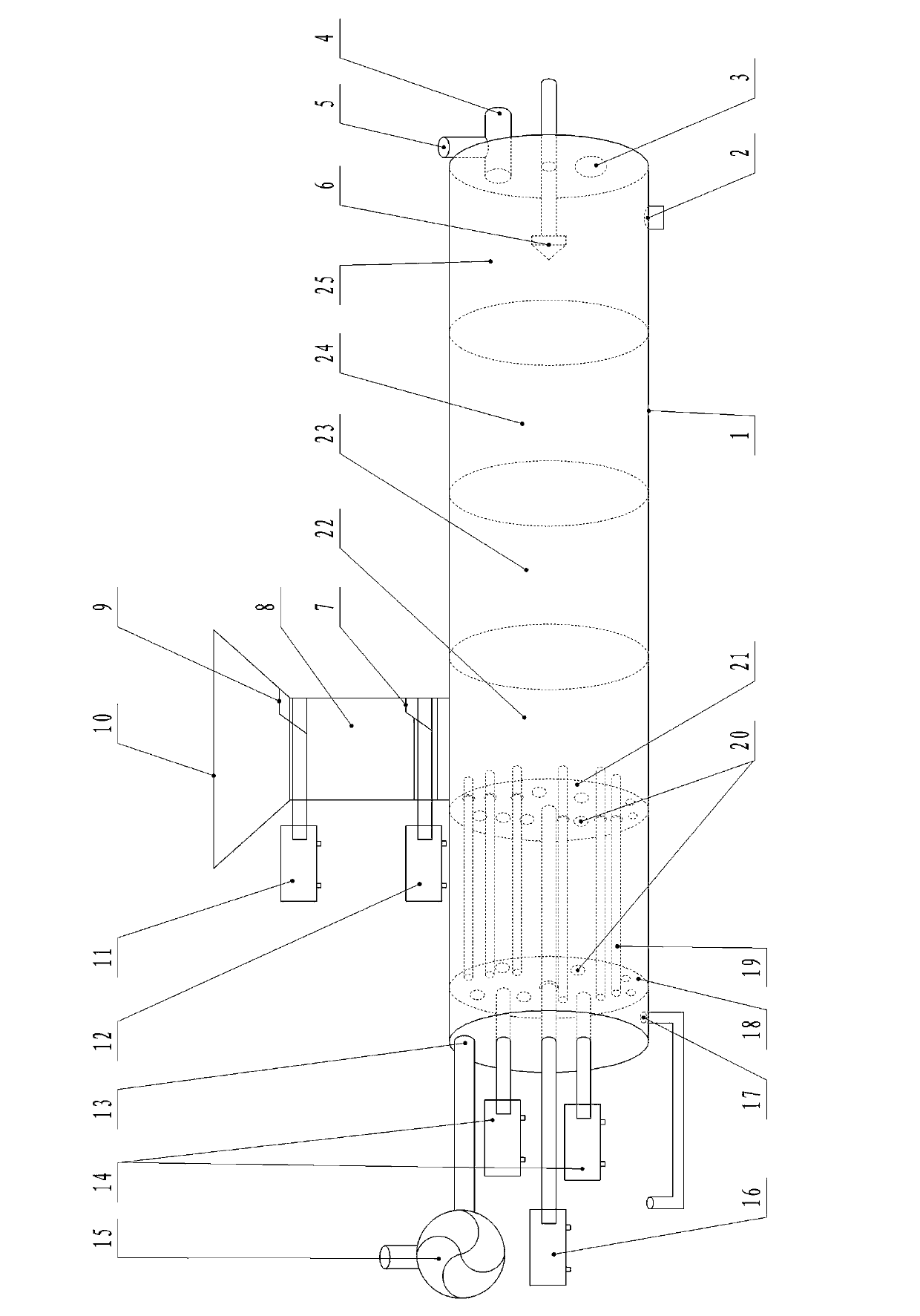

[0015] refer to figure 1 , a horizontal device for continuously producing combustible gas using biomass fuels, comprising a housing 1, the housing 1 is in the shape of a columnar body, placed horizontally, the upper side of the housing 1 is connected to the storage chamber 8, and the storage chamber The upper end of the material chamber 8 is connected with the feed hopper 10; the combustion head 6 is arranged in the inner cavity of the right end of the housing 1, and the air inlet 5 and the waste material outlet 2 are arranged at the right end; The sequence on the right is provided with a punching piston 18 and a pusher piston 21. The punching piston 18 is provided with a plurality of horizontally arranged through rods 19, one end of the through rod 19 is connected with the punching piston 18, and the other end can pass through Pushing piston 21, punching piston 18, and vent hole 20 are arranged on pushing piston 21, and punching piston 18 is connected with second hydraulic cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com