Urea condensate pump

A technology of condensate and urea, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems such as over-temperature and over-pressure that cannot be solved, and achieve the effects of compact structure, convenient installation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

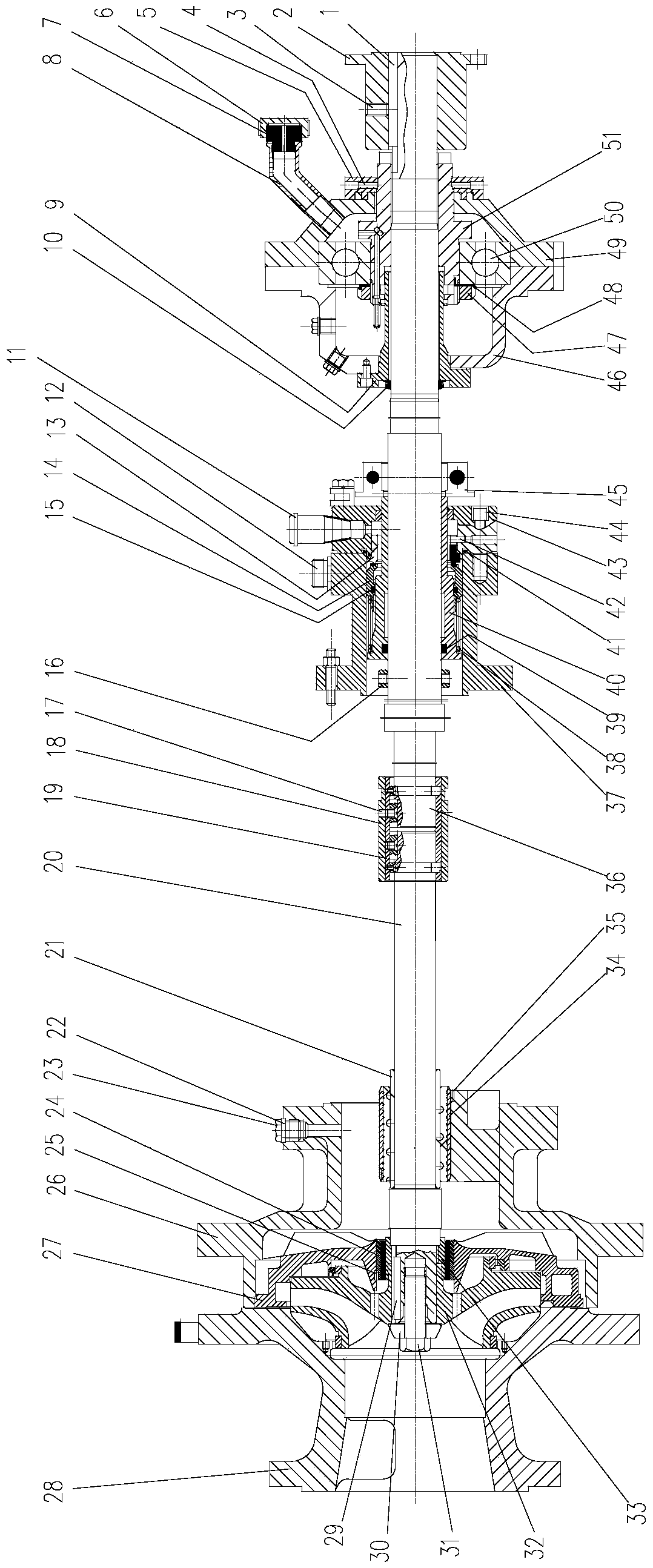

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] Such as figure 1 As shown, a urea condensate pump of the present invention includes a first shaft 20 and a second shaft 36 coaxially arranged, and the right end of the first shaft 20 and the left end of the second shaft 36 are detachably connected together.

[0030] Among them, the first key 1 is installed on the right end of the second shaft 36; the coupling 2 is connected with the second shaft 36 through the first key 1, so as to realize the circumferential fixation between the second shaft 36 and the coupling 2 to transmit torque , and tightened with the first screw 3, so as to play the role of axial fixation; the sealing ring 5 is installed on the third shaft sleeve 51, and fastened with the set screw 4, which exerts a force on the sealing ring 5, thereby It plays a sealing role and improves the sealing effect, which belongs to the mechanical seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com