Gas flow standard device

A standard device, gas flow technology, applied in measurement devices, test/calibration devices, liquid/fluid solid measurement, etc., can solve the problems of unsatisfactory detection accuracy, poor device accuracy, and high environmental requirements, and achieve detection accuracy. and calibration work efficiency, high accuracy, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

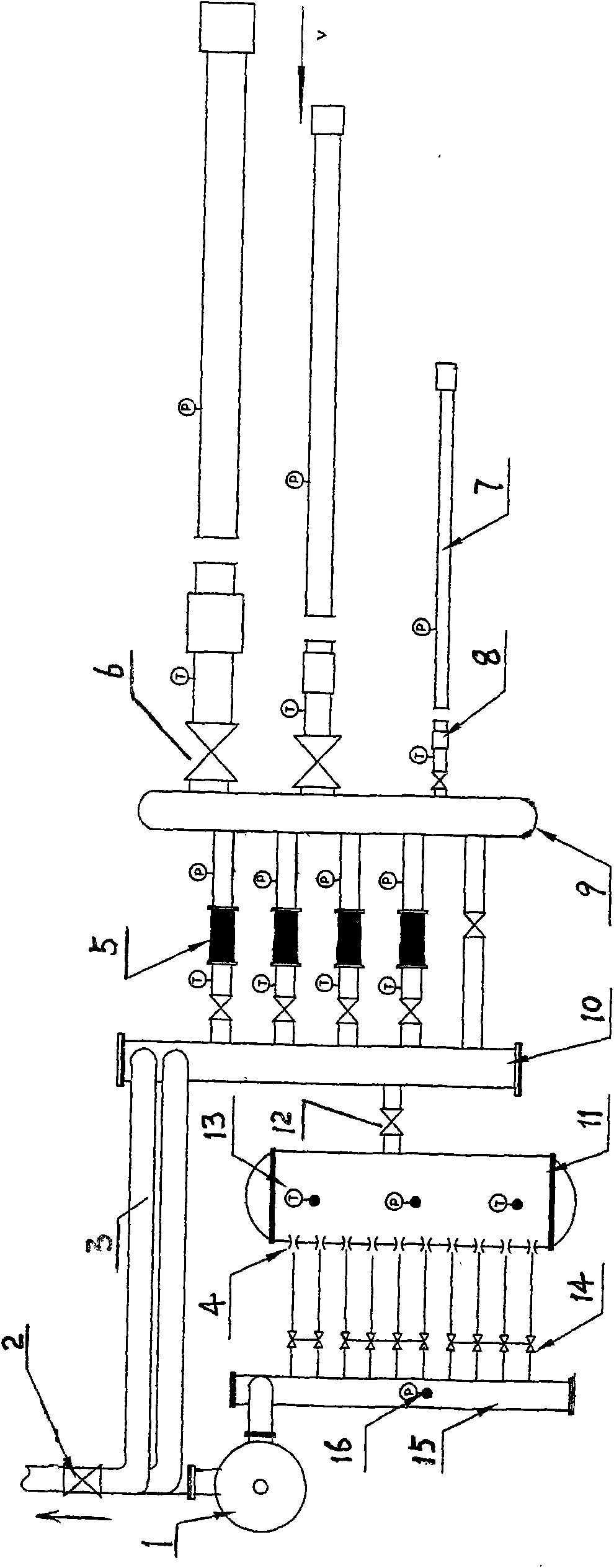

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 As shown, the present invention includes a surge tank 1 whose output end is used to connect a vacuum pump, and whose input end is connected with a nozzle collecting pipe 15 . The nozzle collection pipe 15 is correspondingly connected to the multiple nozzles 4 on the nozzle container 11 through a plurality of first pneumatic ball valves 14 and the cylinder assembly, and a pressure collection point 16 and a temperature collection point 13 are respectively arranged on the nozzle collection pipe 15 and the nozzle container 11 .

[0021] The input end of the nozzle container 11 is connected to the first output end of the standard meter collection pipe 10 through the second pneumatic ball valve 12 . The second output end of the standard meter collection pipe 10 is connected with the induced draft fan through the pipeline 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com