Double standard gas flow device parallel structure and detection method

A standard gas and flow device technology, applied in the field of measurement, can solve the problems of inability to expand the flow range and large pressure loss, and achieve the effects of rich comparison methods, small pressure loss and large flow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

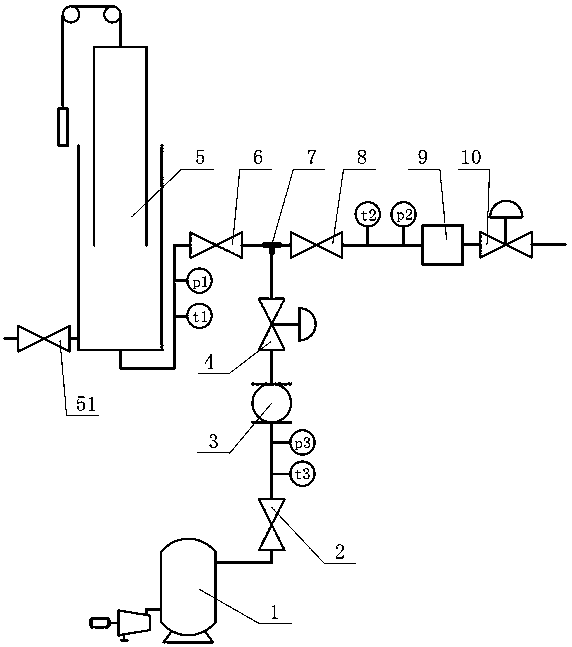

[0014] Such as figure 1 As shown, a parallel structure of a double-standard gas flow device: it includes: gas source 1, stop valve 2, flow meter 3 to be tested, flow regulating valve 4, bell jar 5, on-off valve Ⅰ 6, tee 7, on-off valve Ⅱ8. Standard gas flow meter 9. Gas resistance / flow regulating valve 10. The gas source 1 is connected with the flow meter 3 to be checked through the shut-off valve 2 . A pressure sensor p3 and a temperature sensor t3 are respectively connected to the connecting pipe between the output port of the shut-off valve 2 and the input port of the tested flow meter 3 . The tested flow meter 3 communicates with the input port of the tee 7 through the flow regulating valve 4 . The output port of the tested flow meter 3 communicates with the input port of the flow regulating valve 4 . The output port of the flow regulating valve 4 communicates with the input port of the tee 7 . The first output port of the tee 7 is connected with the bell jar 5 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com