Large-range flow meter and large-range flow measuring method

A large-scale, flowmeter technology, applied in volume measurement, liquid/fluid solid measurement, measuring devices, etc., can solve the problems of increasing the liquid flow resistance of the main pipeline, inconvenient maintenance, etc., and achieve simple structure, high sensitivity, and index sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Manual type large-range flowmeter:

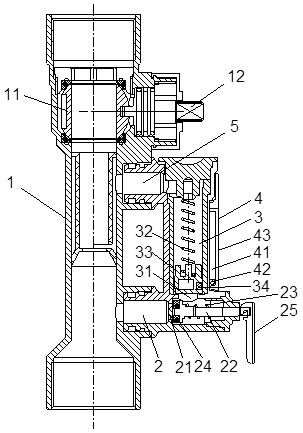

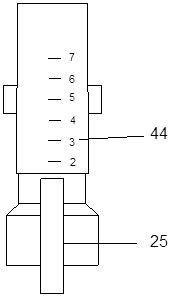

[0028] Such as Figure 1-4 As shown, this embodiment describes in detail the specific structure and usage method of the wide-range flowmeter in the present invention in conjunction with a flowmeter-type balance valve.

[0029] The flow meter type balancing valve includes a valve body 1, and a ball valve 11 and a valve stem 12 are installed in the valve body 1.

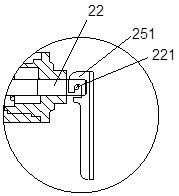

[0030] The balancing valve includes a large-range flowmeter, and the large-range flowmeter includes a housing detachably installed on the side of the valve body 1 . Compared with the main passage in the valve body, a bypass passage of the valve body is formed in the casing. The bypass channel includes a liquid inlet channel 2 , a measuring channel 3 and a liquid outlet channel 5 connected in sequence, and both the liquid inlet channel 2 and the liquid outlet channel 5 are connected to the valve body 1 .

[0031] In this structure, the measuring channel 3 inclu...

Embodiment 2

[0054] Embodiment 2 Automatic wide-range flowmeter

[0055] The automatic wide-range flowmeter in this embodiment has the same structure as the manual wide-range flowmeter in terms of liquid inlet channel, measurement channel, and liquid outlet channel.

[0056] The difference lies in the opening control mechanism, which includes:

[0057] Such as Figure 5 As shown, the inner end of the piston is provided with a pressure sensor, the piston rod is connected to the motor, the motor is connected to the controller, and the controller is connected to the switch and the pressure sensor; when the switch is turned on, the controller obtains the water pressure of the pressure sensor Information, when the water pressure information is in the first preset value interval, the motor drives the piston rod to move, so that the piston leaves the piston valve seat to the first stroke, the liquid inlet channel is opened, and maintains a first fixed opening; when the water pressure information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com