Patents

Literature

63results about How to "No impact noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-noise strong-impact weak-recoil electric hammer drill

The invention is low-noise, strong-impulsion and weak-recoil electric hammer anvil, and belongs to the electric tools field. It is to solidify the kinematical bearing seat with eccentric block on the two plate springs. The plate springs, the base, the impulsion rod and the anvil rod are connected orderly. The impulsion can slide in the shaft sleeve and has the buffer and the spacing springs. When the electric machine driving the eccentric block to revolve, the circle vibration produced drives the anvil rod produce impulsion under the function of the plate spring, and meanwhile the electric machine shaft transmits the revolving movement to the anvil rod through the gear transmission and makes the anvil rod has hammer and anvil functions. The device does not have inner noise because it is without inner impulsion. The impulsion of the anvil rod is decided by the moment of the eccentric block and the revolving speed of the electric machine. The recoil is small as without the external power of the worker.

Owner:贺启宇

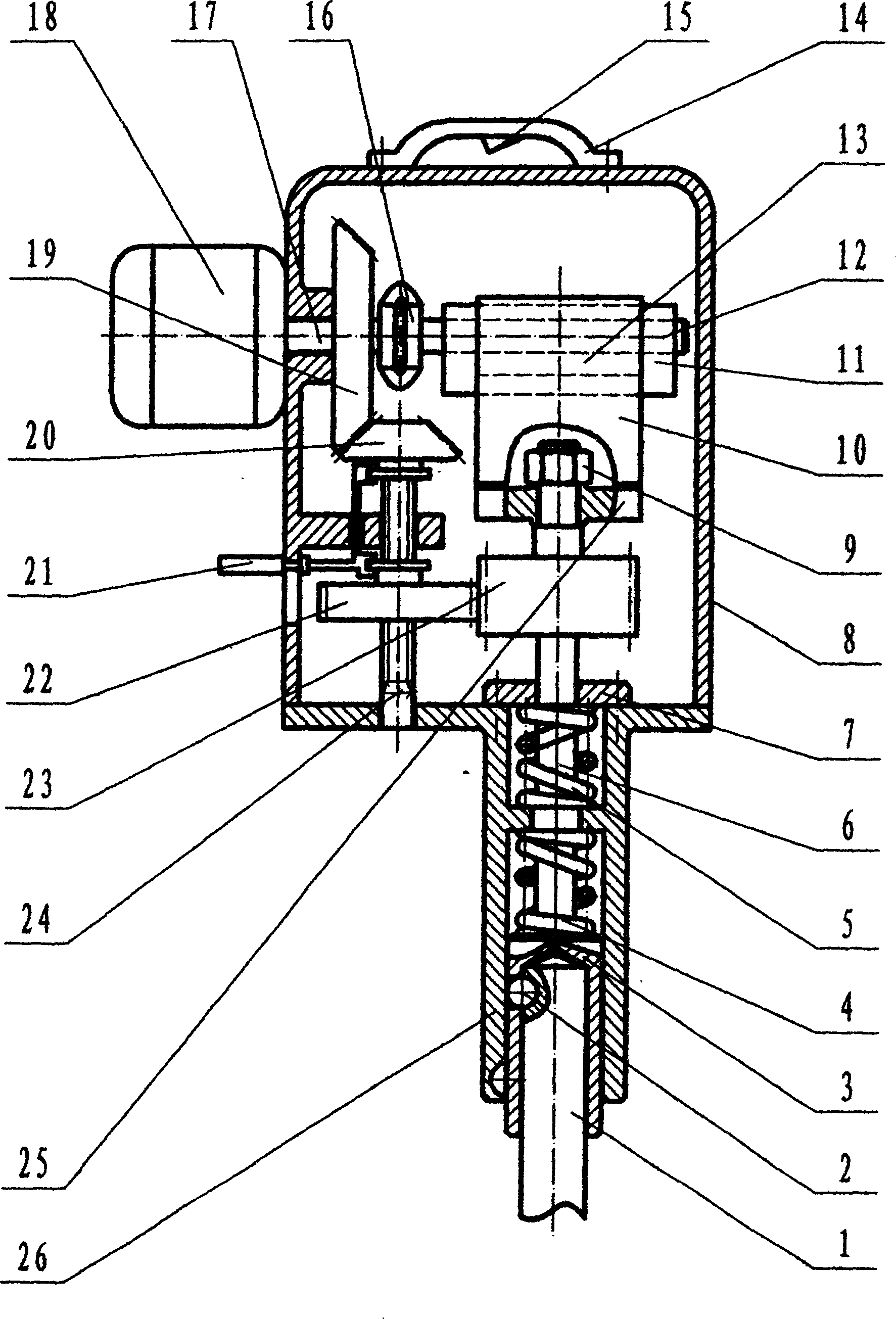

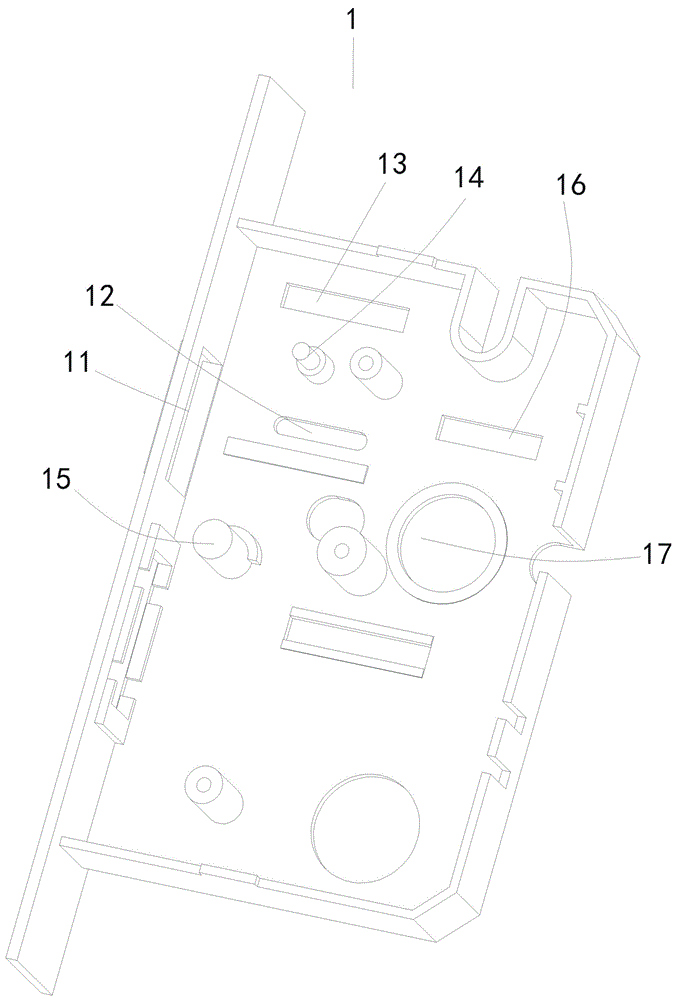

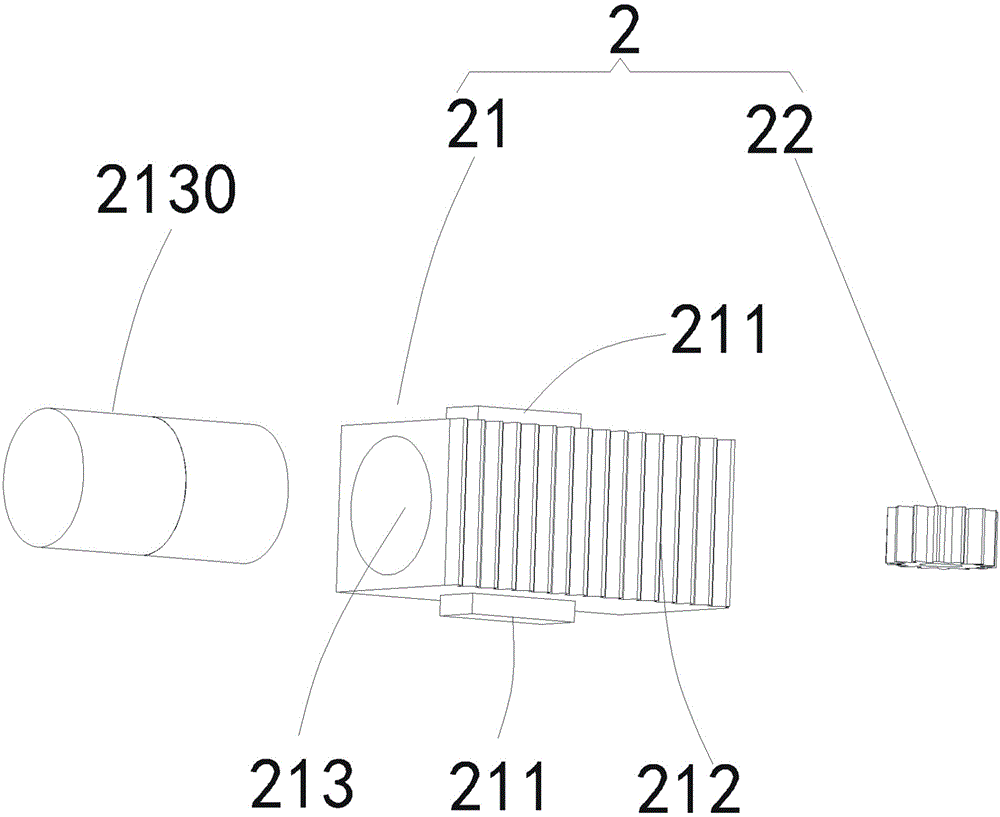

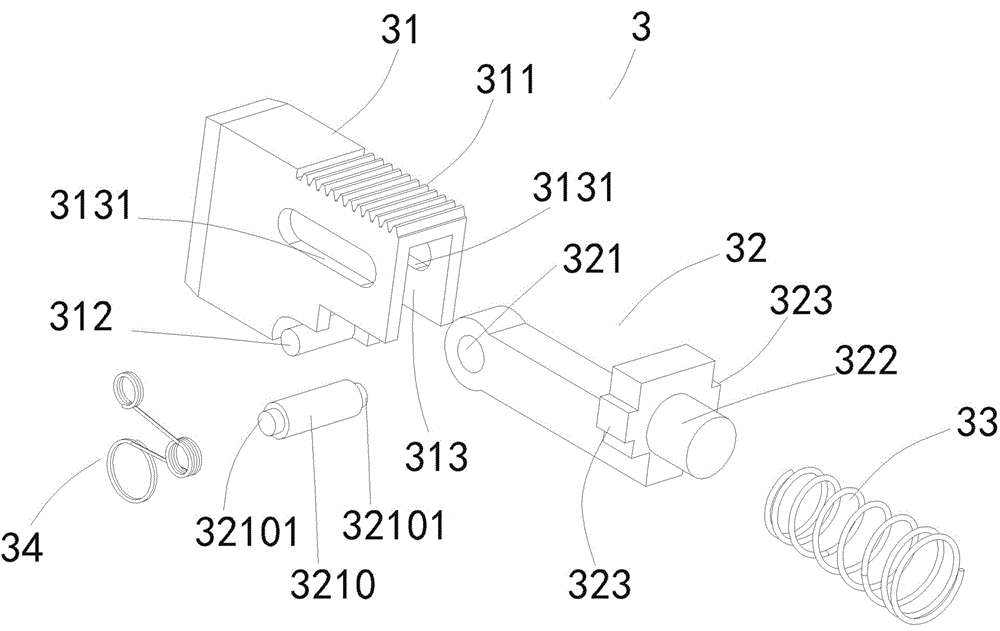

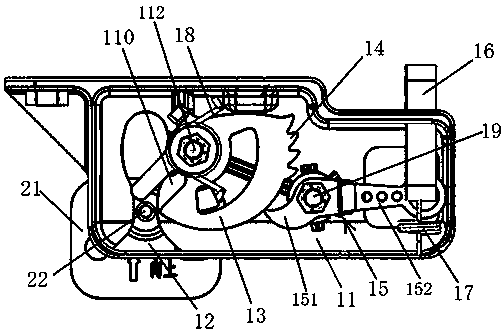

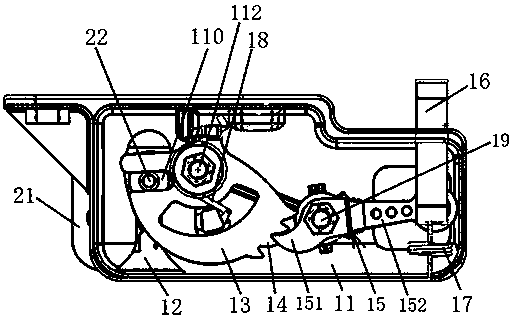

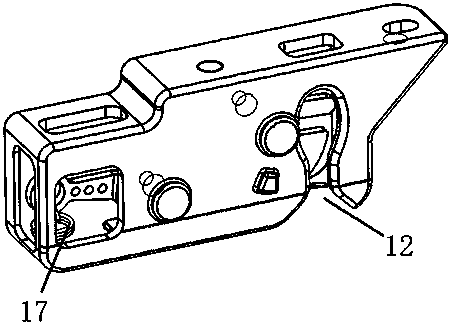

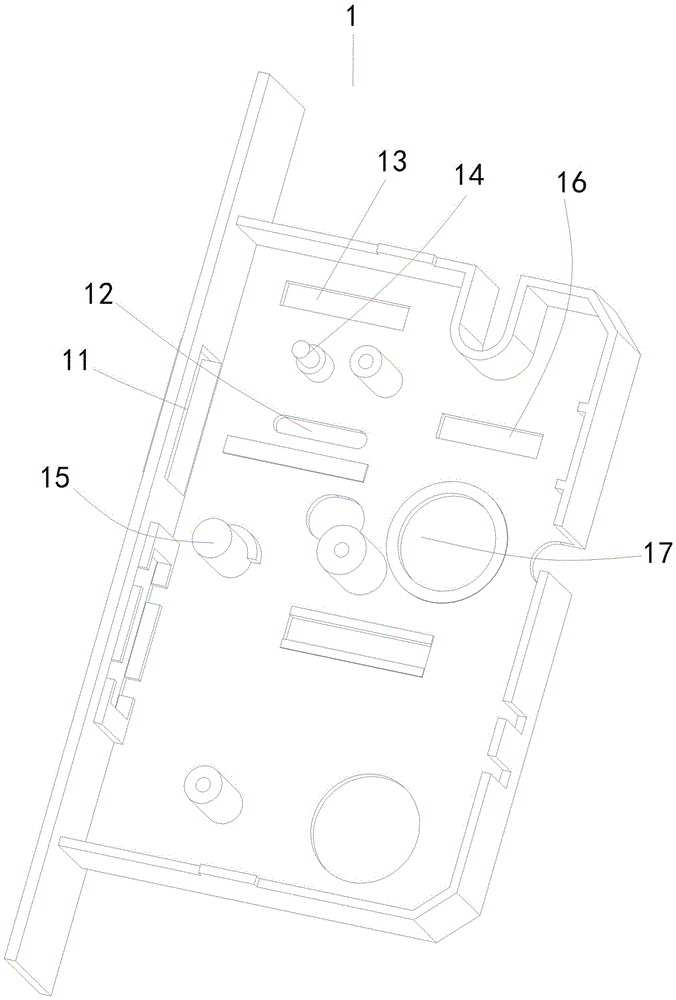

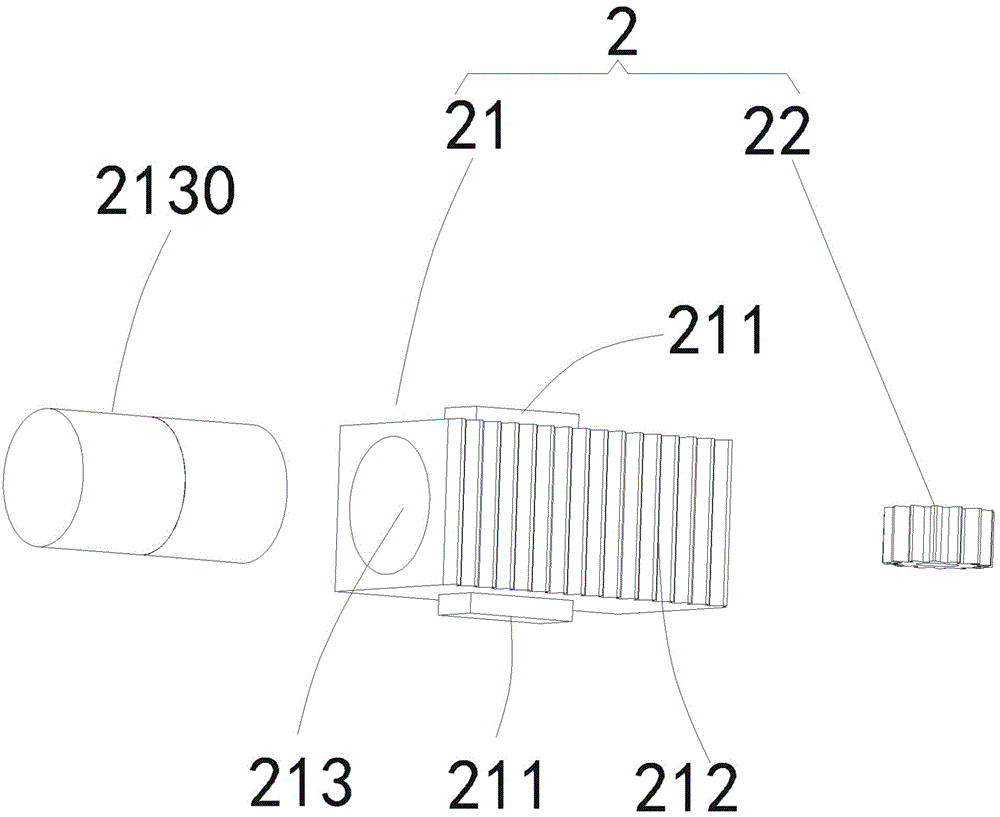

Magnetic silent lock body

ActiveCN104314381AEasy to useGood transmission effectNon-mechanical controlsEngineeringTorsion spring

The invention relates to a hardware door lock fitting, and discloses a magnetic silent lock body. The magnetic silent lock body is provided with a box bottom assembly, a driving assembly, a deadbolt assembly, a buckling box assembly and a handle stirrer, wherein the driving assembly consists of a slide block, a gear and a three-circle torsion spring; the deadbolt assembly consists of a deadbolt, a deadbolt pull rod and a reset spring; the top of the deadbolt is provided with a rack B; the box bottom assembly is provided with a gear positioning column; the slide block is provided with a rack A and a magnet positioning hole; the deadbolt is provided with a rack B; a magnet B is arranged in the buckling box assembly; the magnet A is fixedly embedded into the magnet positioning hole in the slide block; the slide block is arranged in the box bottom assembly; the gear passes through the gear positioning column, and is meshed with the rack A and the rack B simultaneously. During door closing, the deadbolt extends outwards under the same-pole repellant force of the magnet A and the magnet B. The movement of the lock body is driven by the gear and the racks, and the overall movement process is stable and reliable without collision, so that the use handfeel of the lock body is improved, and a silencing effect is achieved.

Owner:GUANGDONG MINGMEN LOCKS IND

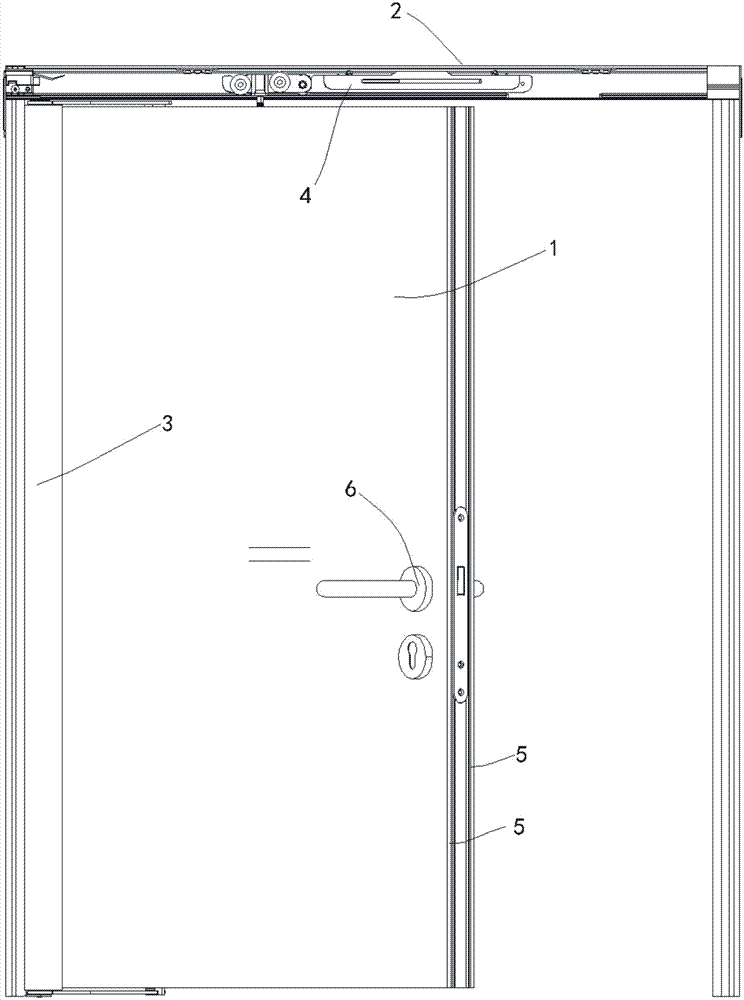

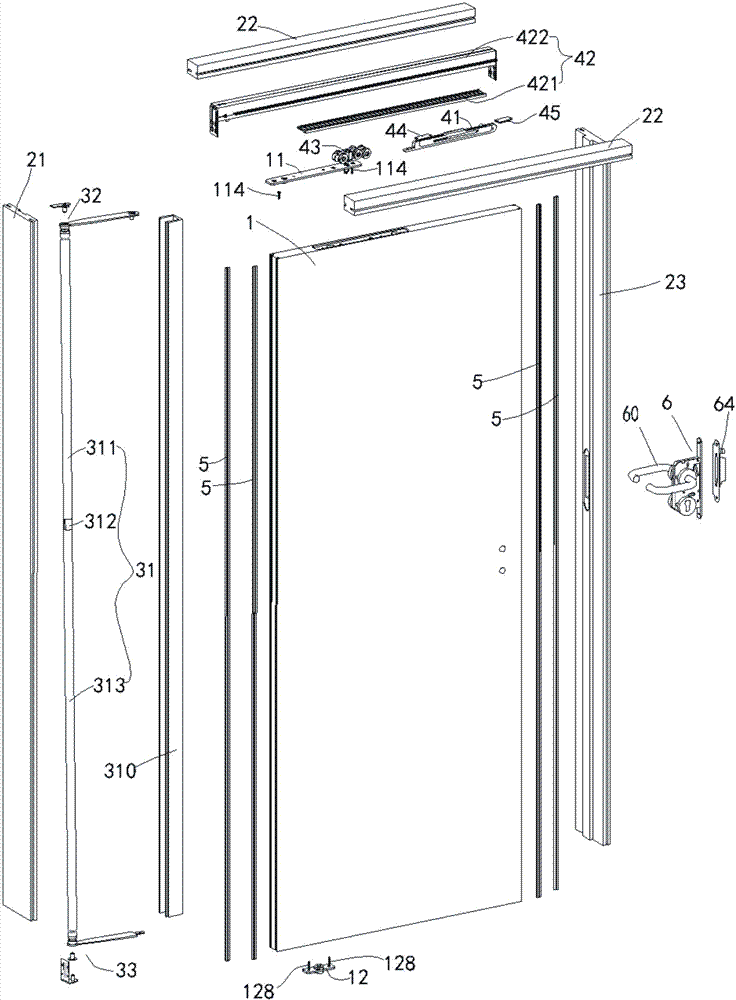

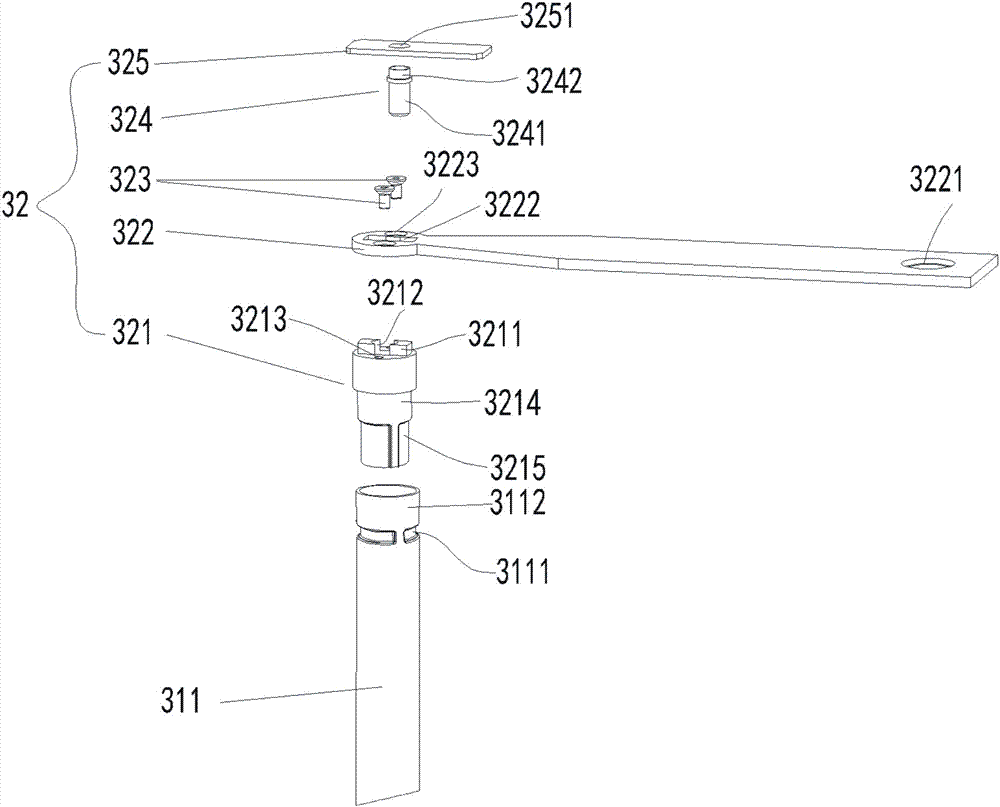

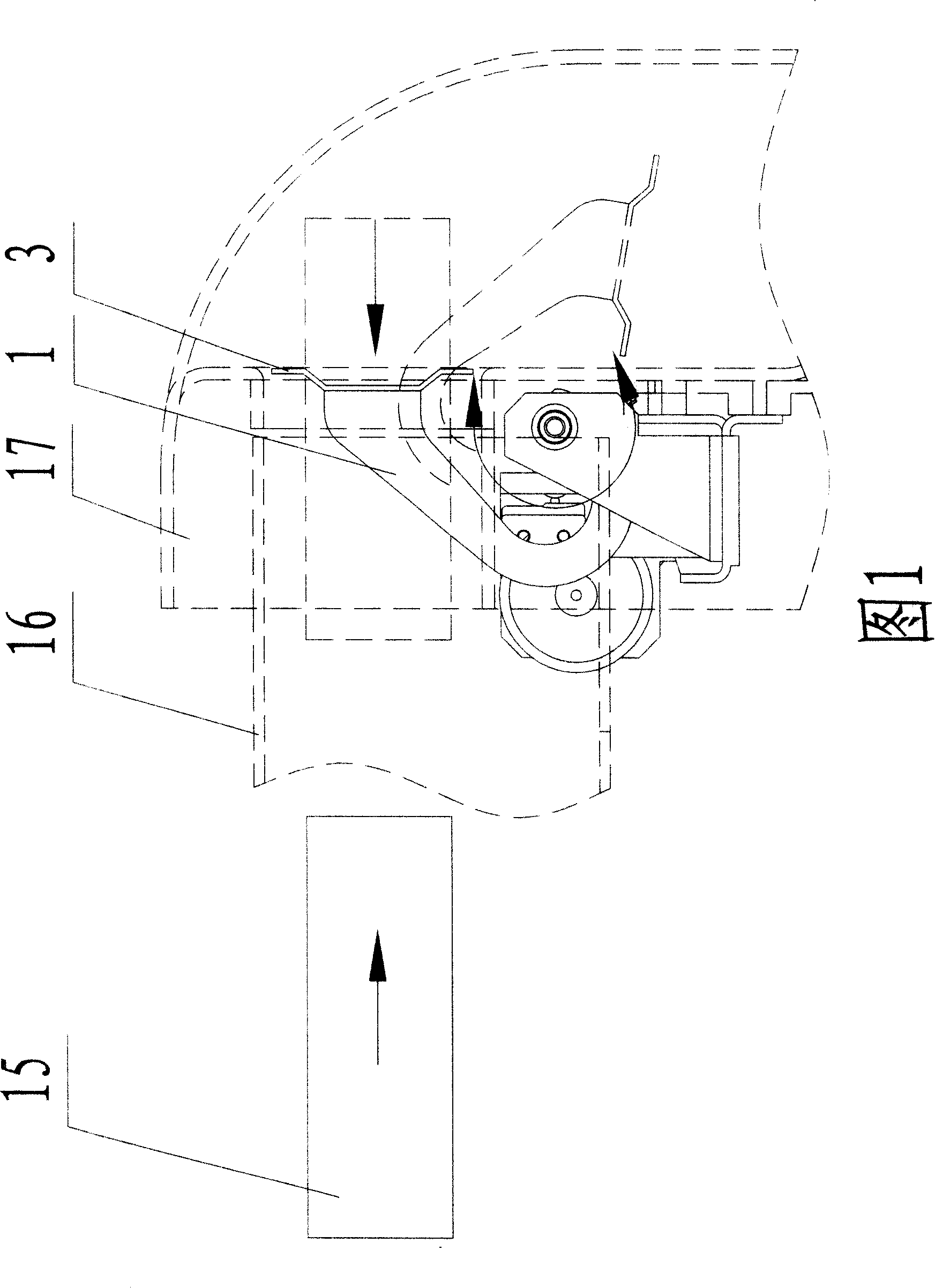

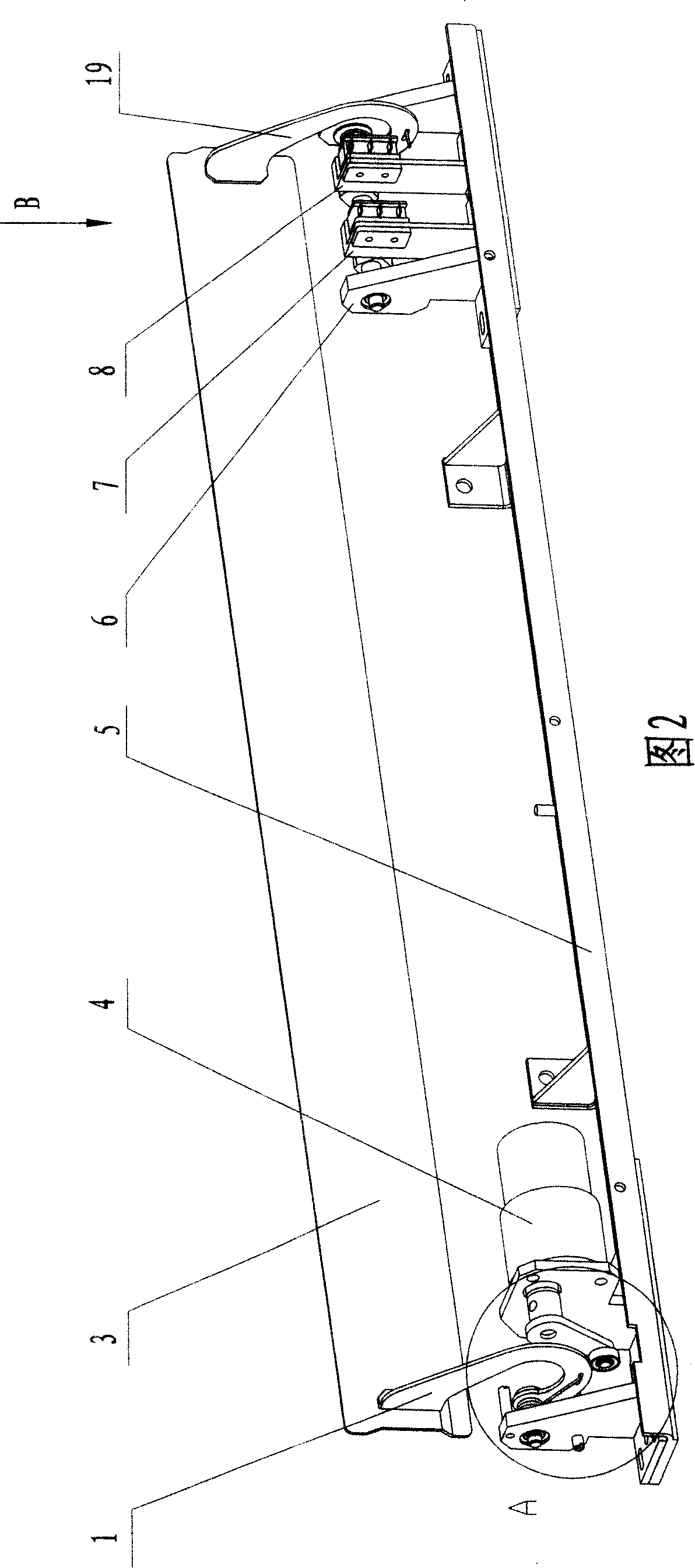

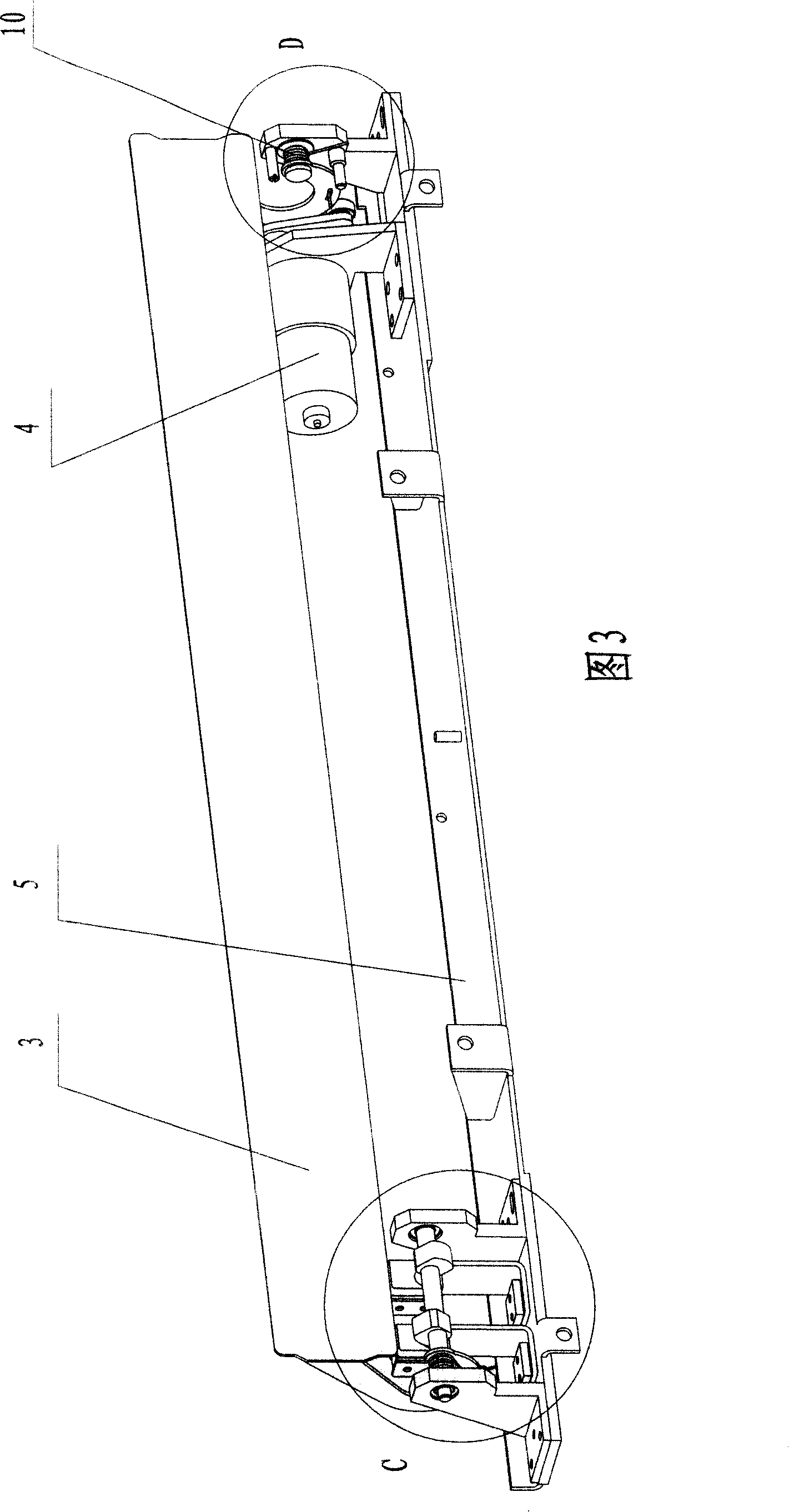

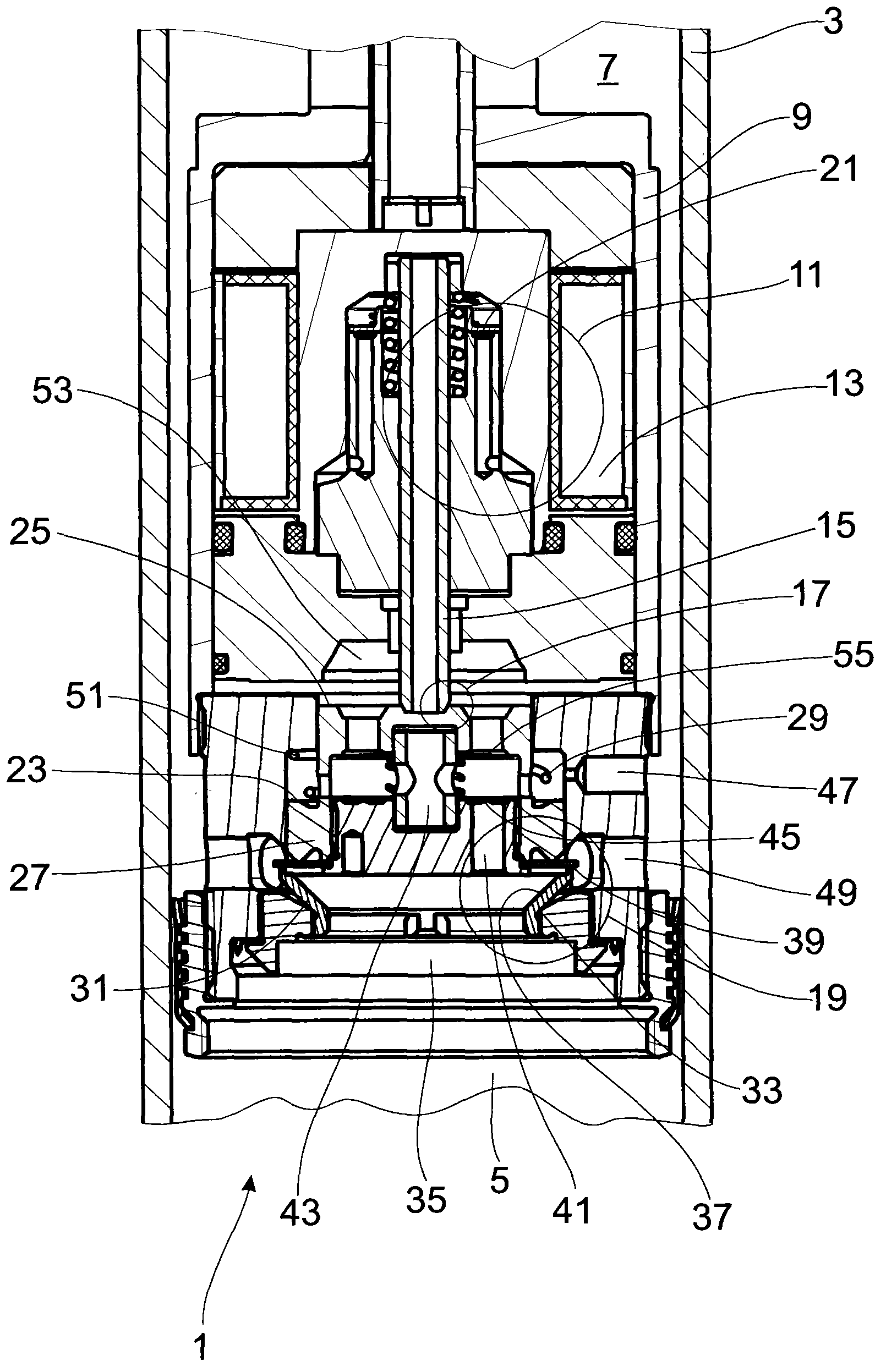

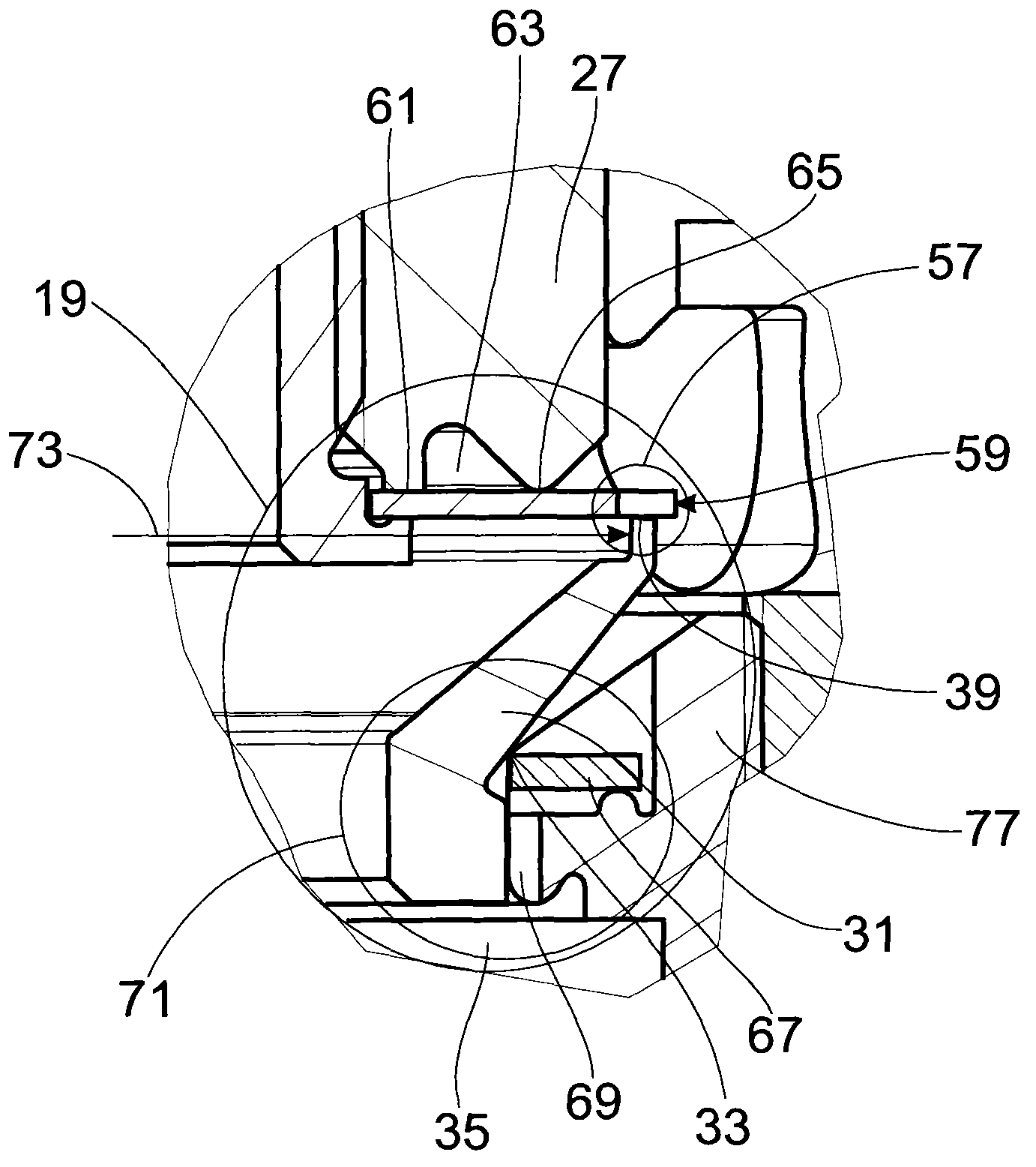

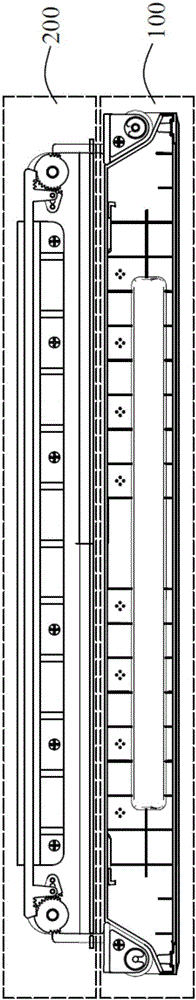

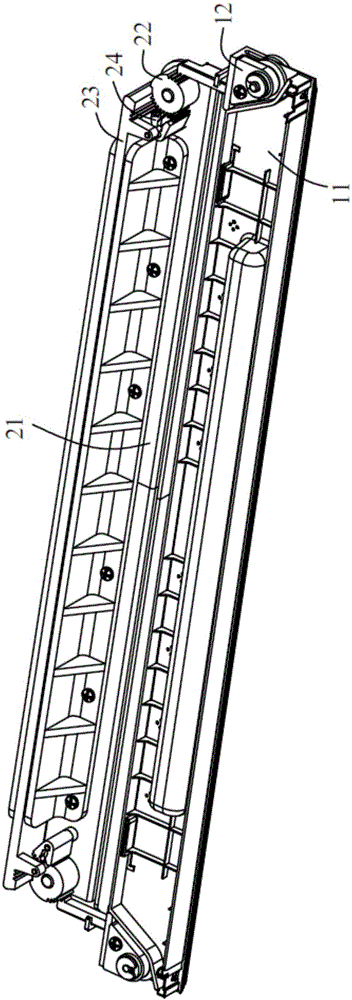

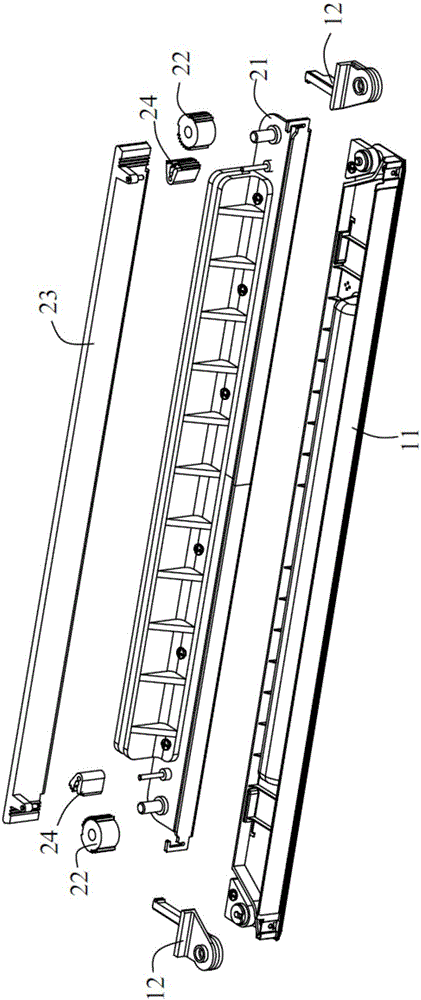

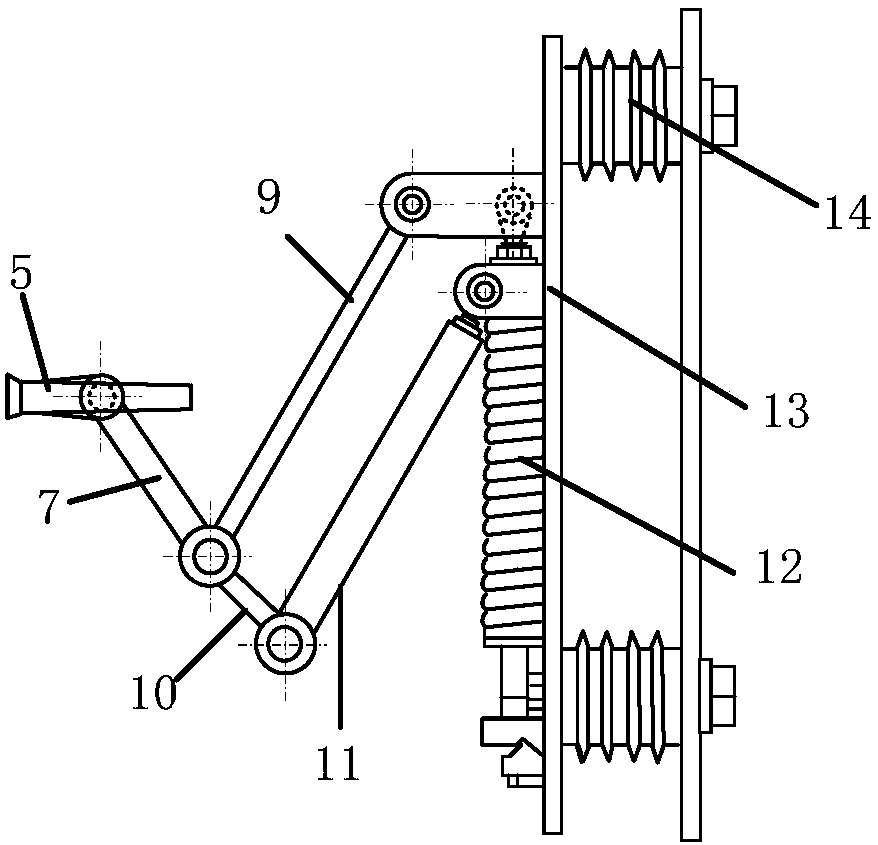

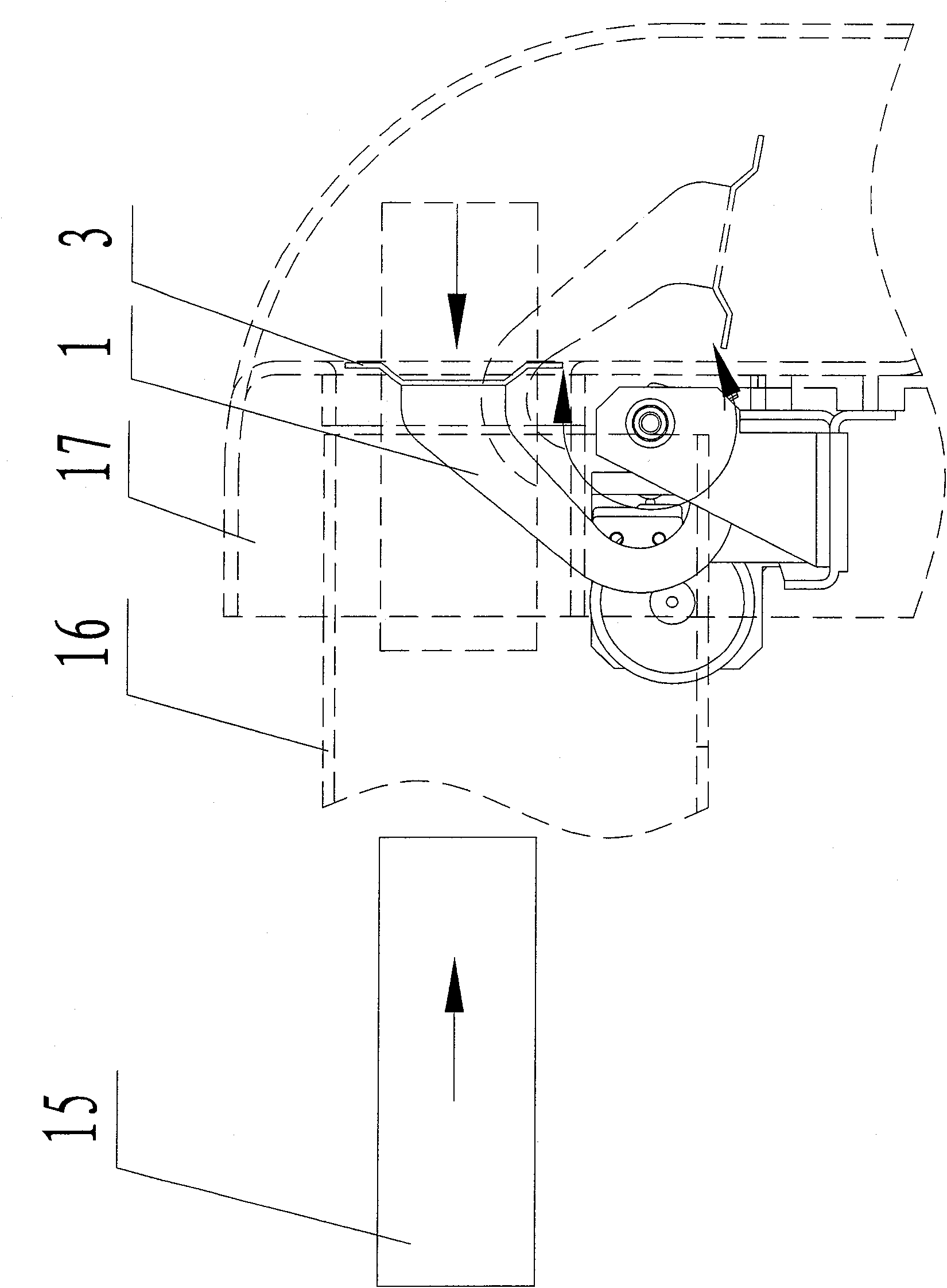

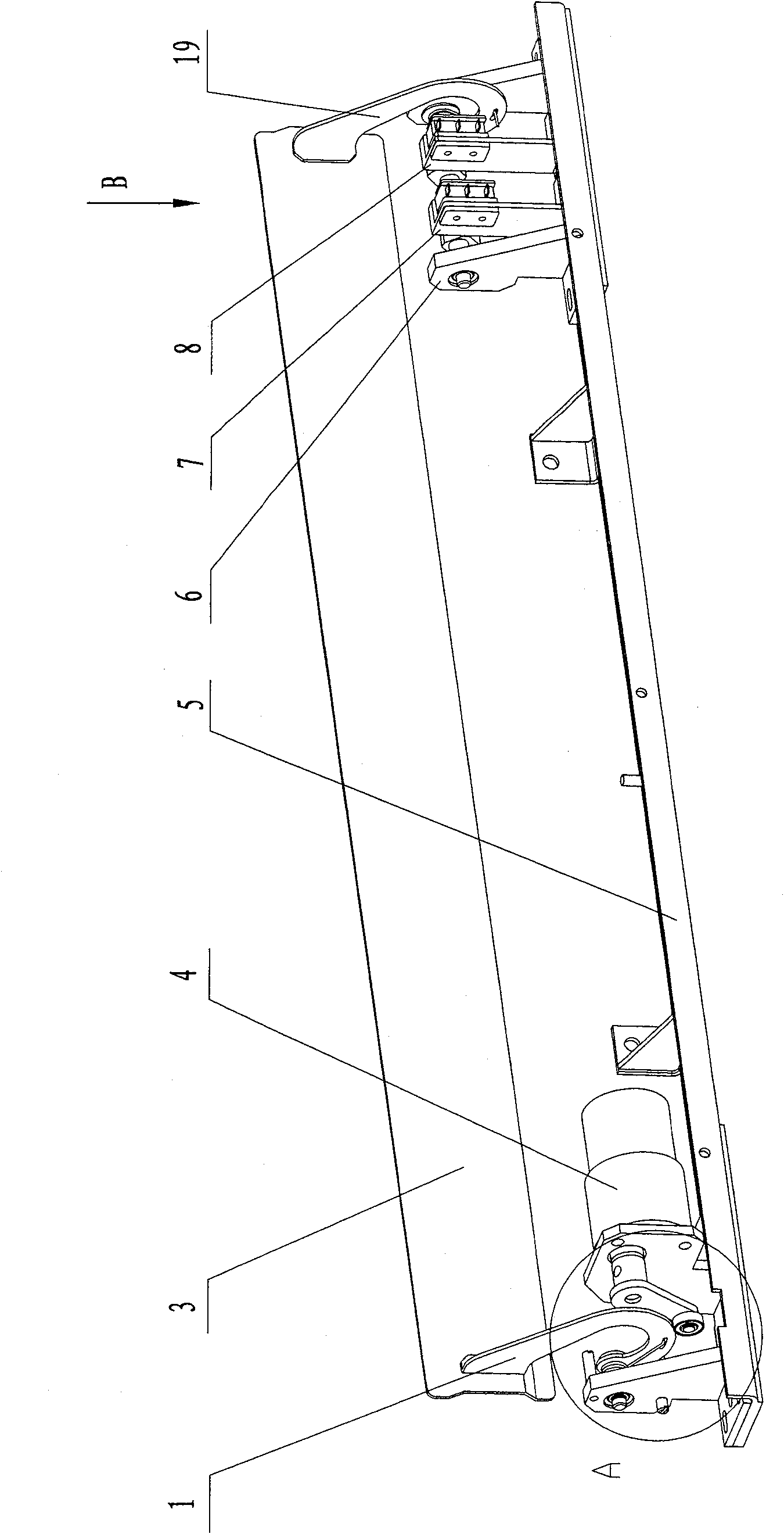

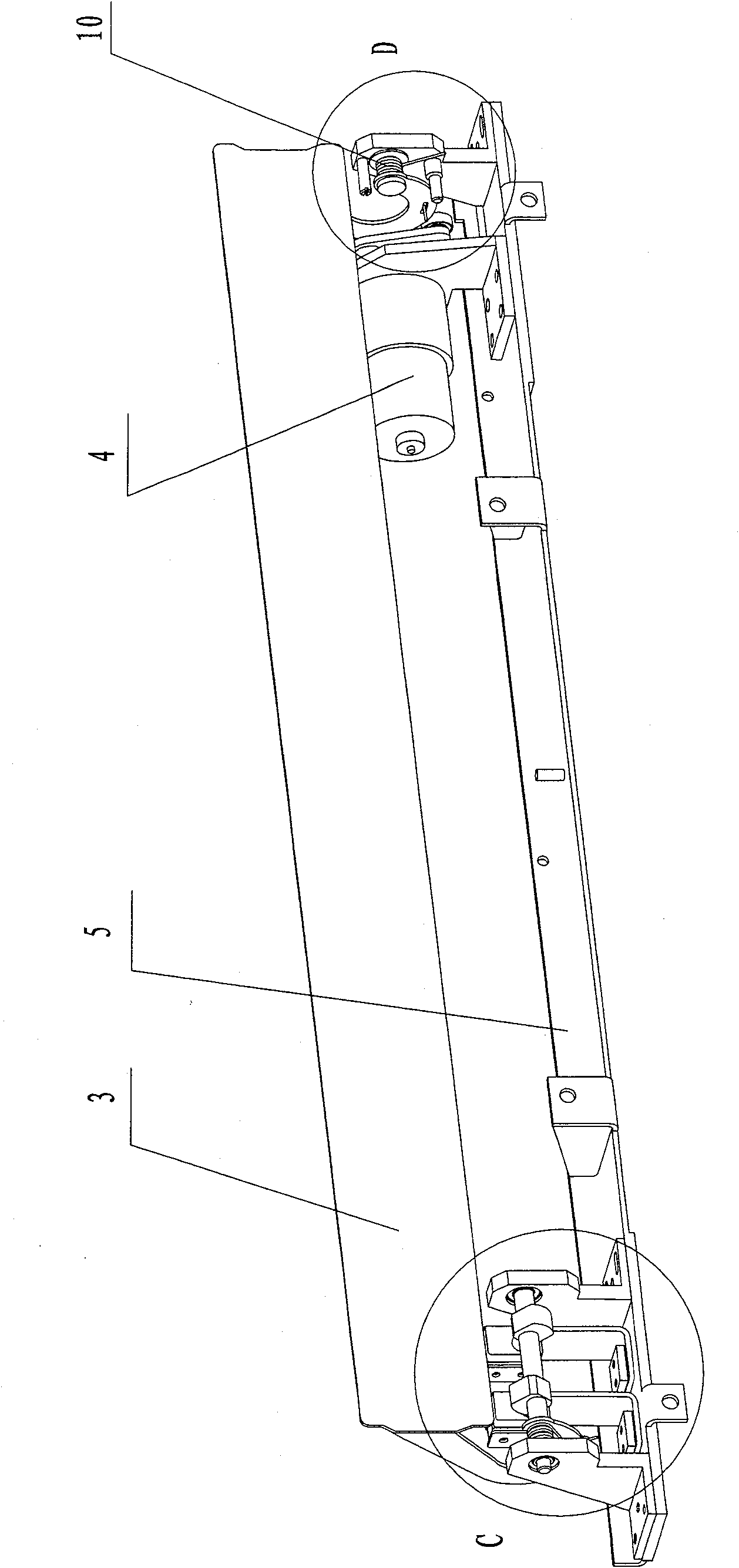

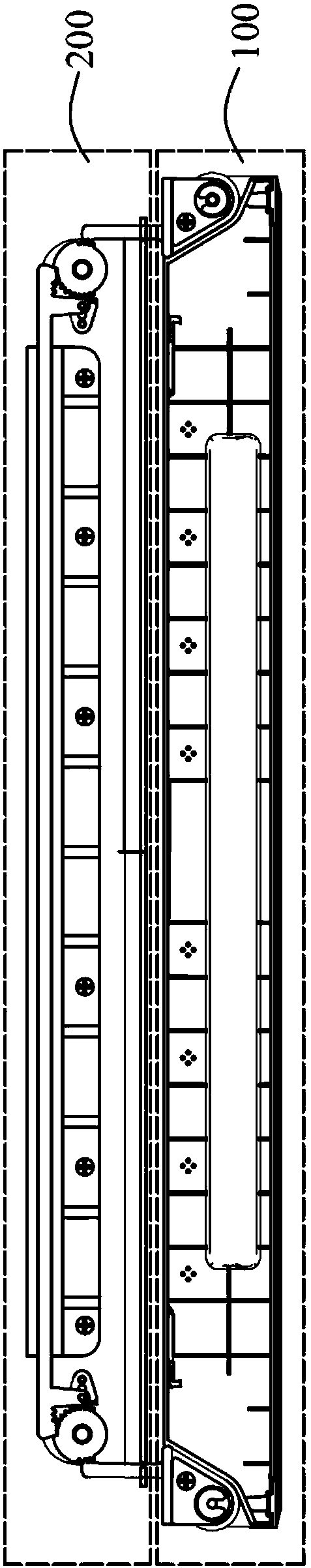

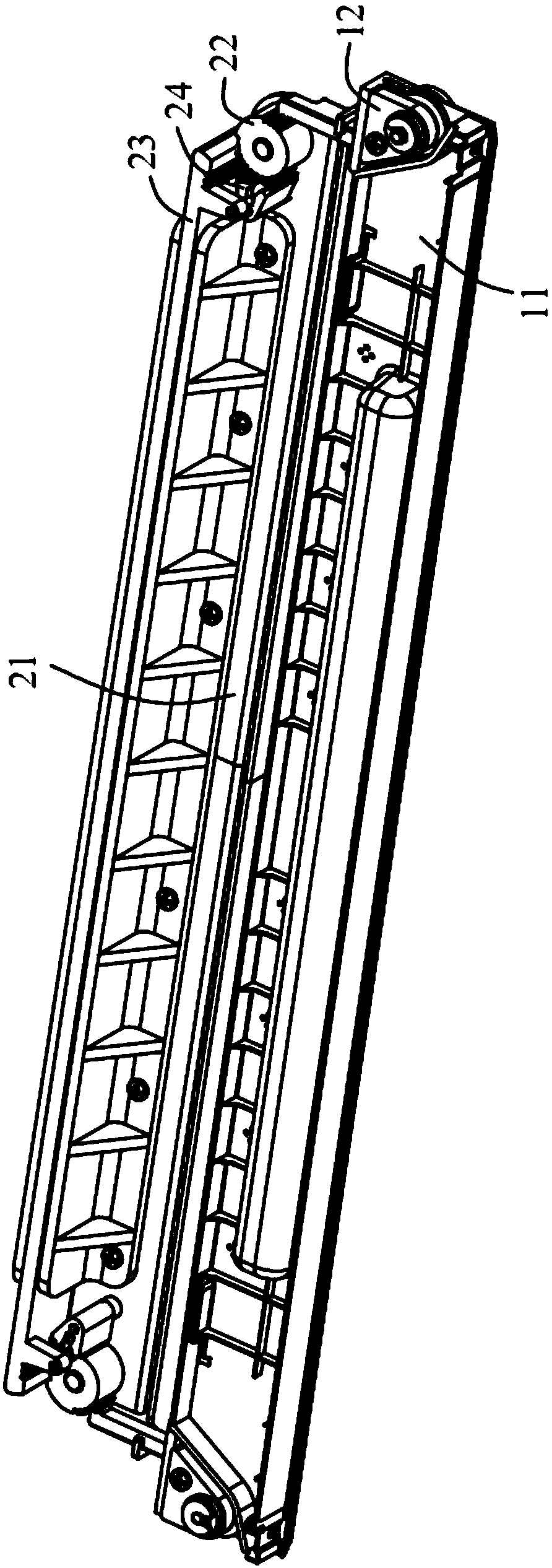

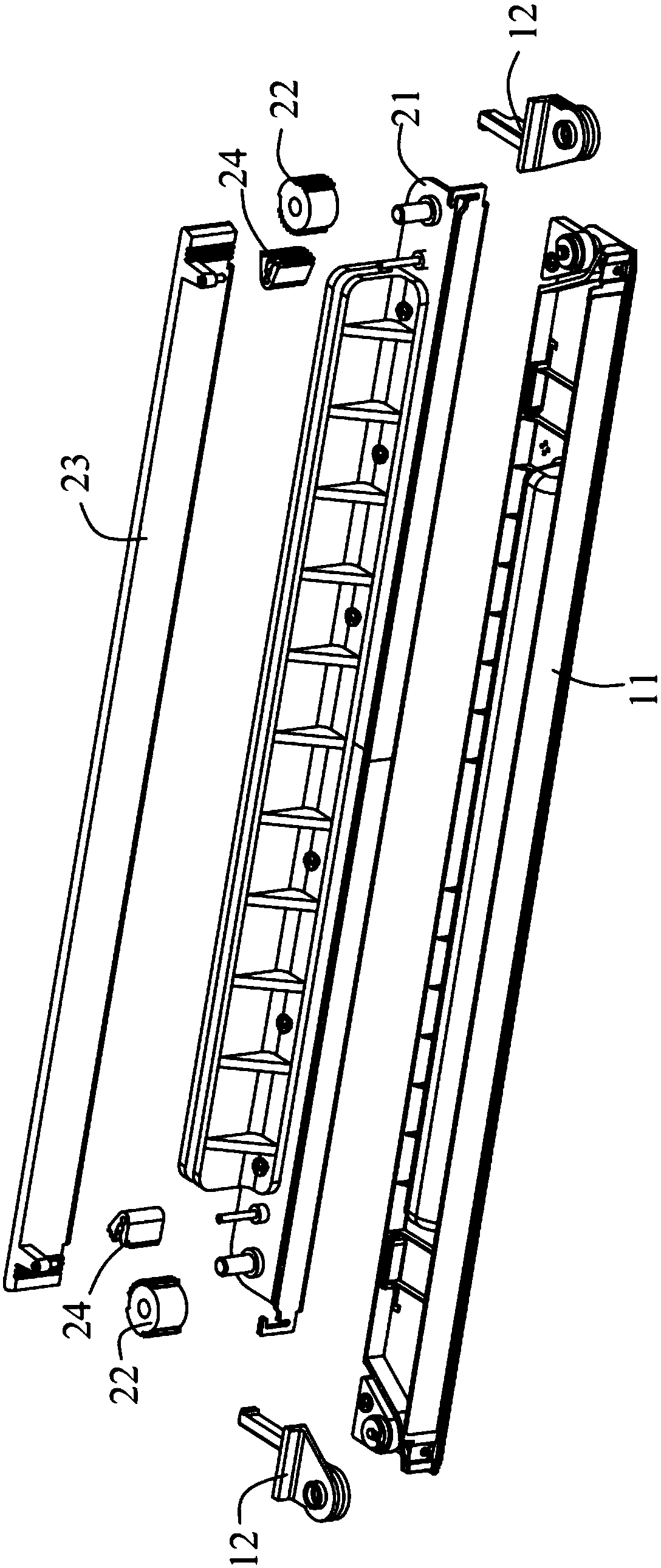

Noiseless vertical hinged lateral overturned door system

ActiveCN104328990AEliminate impact noiseReduce the impactWing arrangementsWing suspension devicesEngineeringPulley

The invention relates to a vertical hinged lateral overturned door system, and provides a noiseless vertical hinged lateral turned door system. An overturn mechanism is arranged between a door leaf and a rotating shaft vertical plate of a door frame, so that the door leaf is overturned laterally in the process of horizontally pushing a door, and a door-opening sweeping space is reduced; meanwhile, a buffer component is arranged in the overturn mechanism, and friction during rotation is reduced; damping pulley mechanism is arranged between a lintel horizontal plate and the door leaf, and collision between the door leaf and the door frame is eliminated in the door opening and door closing travels; side edges of the door leaf is provided with sealing strips to further reduce the collision between the door leaf and the door frame and achieve a soundproof effect; the locking end of the door leaf is provided with a noiseless lock body, and noise in the locking and unlocking process is avoided. According to the scheme, the noise generated in the door using process is comprehensively eliminated, and home and office environments are silenced.

Owner:GUANGDONG MINGMEN LOCKS IND

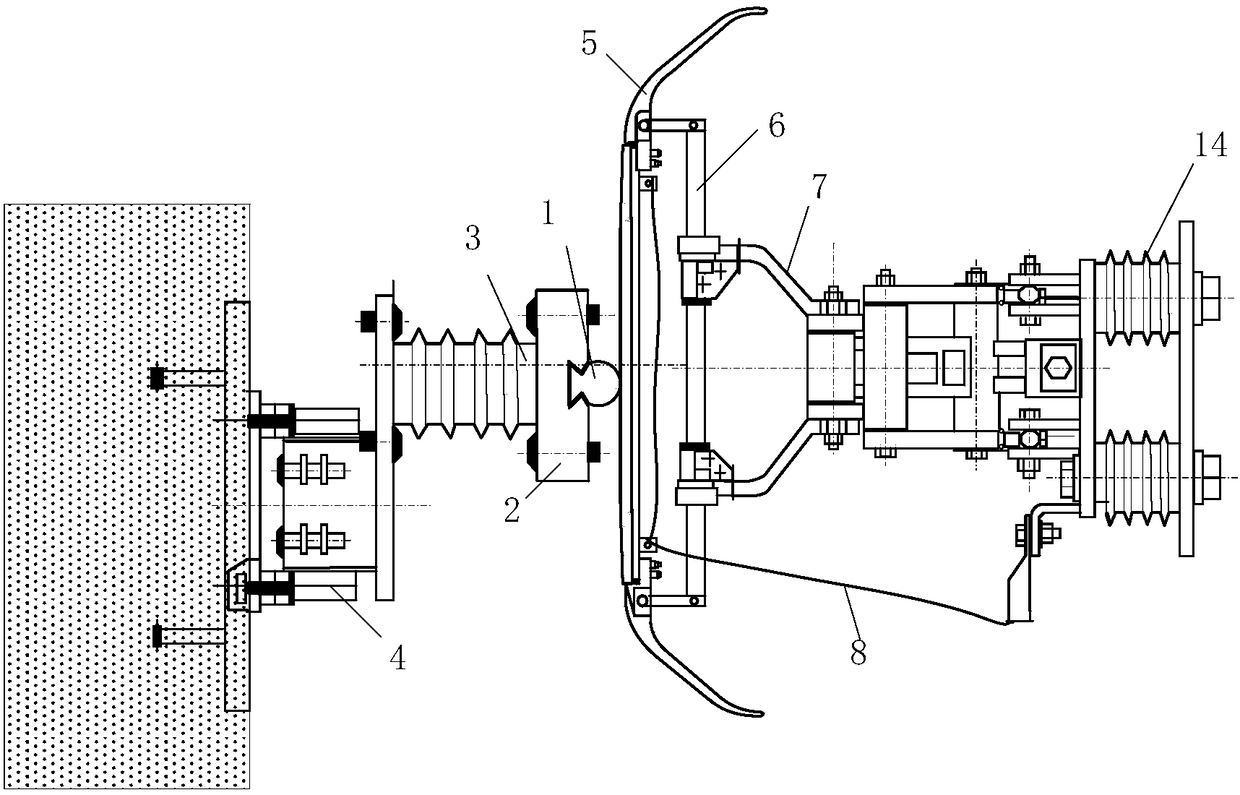

X ray machine spot film system electric door device

InactiveCN101211100ANo impact noiseImpact noise is not generatedRadiation diagnosticsPhotographyX-rayEngineering

The invention relates to a spot film system of a X-ray machine, in particular to an electrically operated door device of the spot film system of the X-ray machine, which comprises rocker arms, a spot film door fixed thereon and a motor arranged on a support board; wherein the motor is arranged at one end of the support board and is connected with a first rocker arm of the end via a swing rod; the other end of the support board is provided with a door rotating shaft and an angle positioning device which synchronizes with the door rotating shaft, a second rocker arm of the end is arranged on the door rotating shaft; and torsion springs are arranged on the first and the second rocker arms. The rotation of the motor of the invention is controlled by two travel switch components, the operation is balanced and noiseless, and has no adverse effects on the spot film system; furthermore, the occupying space is small.

Owner:NEUSOFT MEDICAL SYST CO LTD

Adjustable damping valve arrangement

InactiveCN103511543ANo impact noiseGood damping force transitionSpringsShock absorbersEngineeringActuator

Owner:ZF FRIEDRICHSHAFEN AG

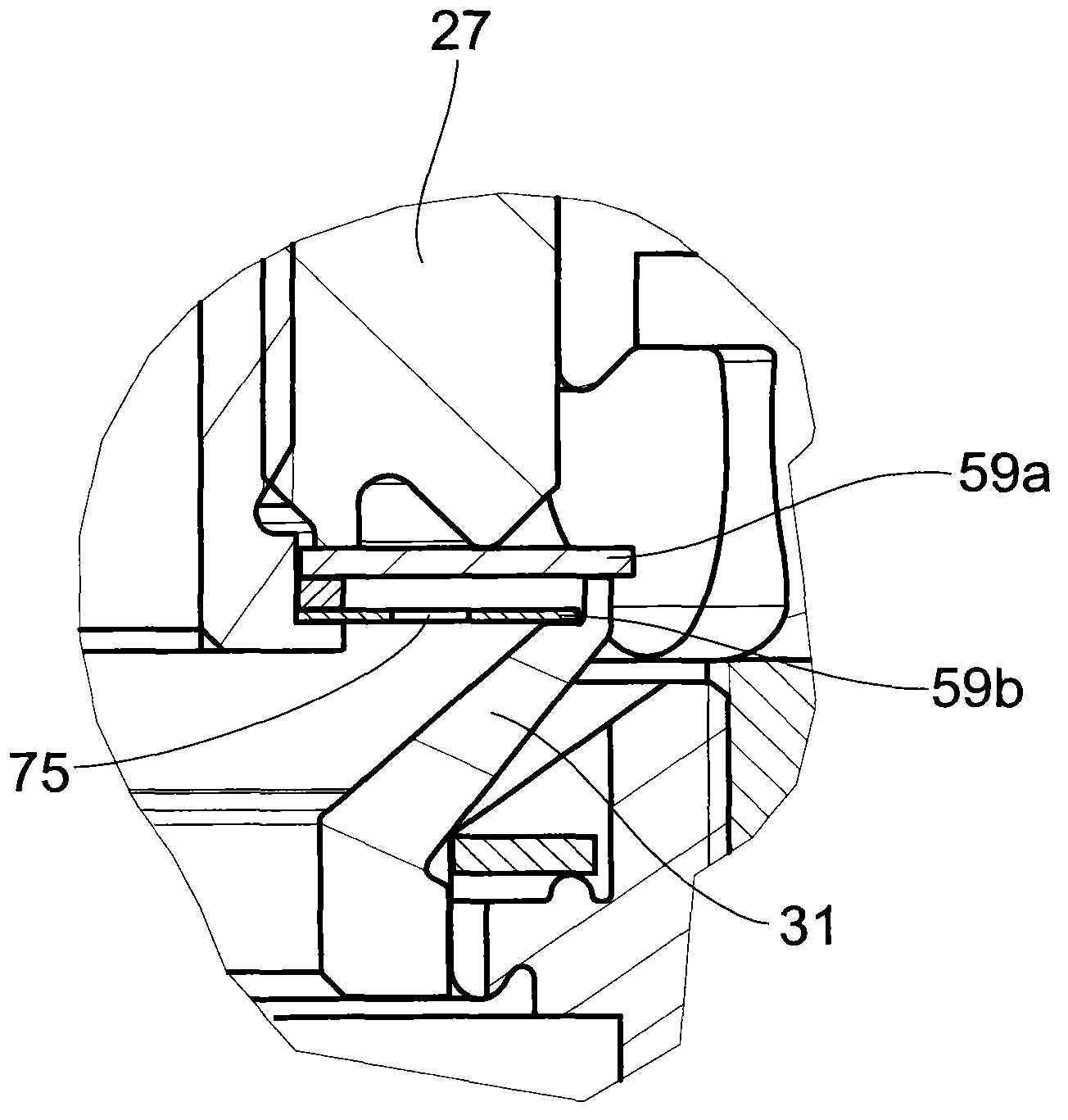

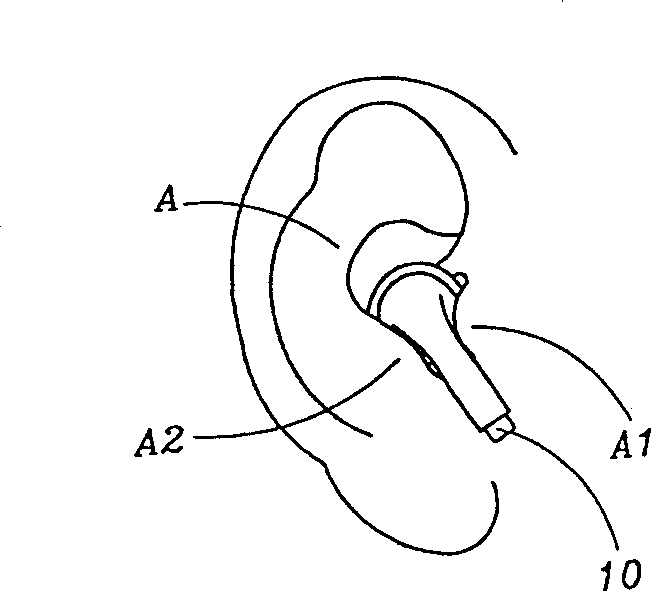

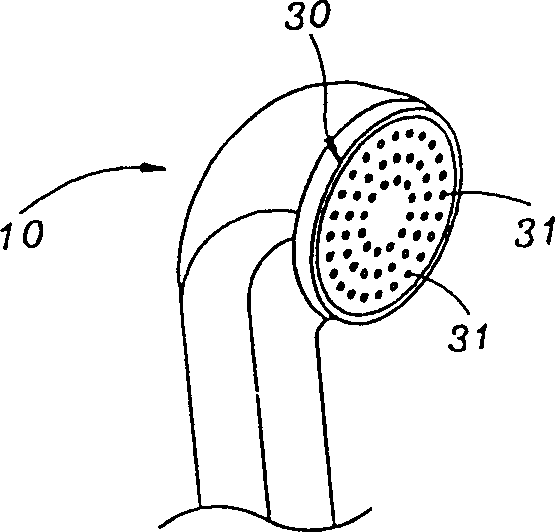

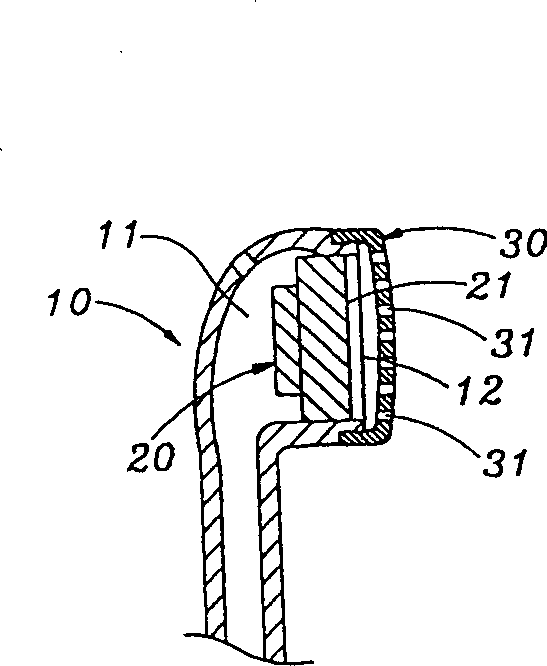

Earphone without impulse noise and surrounding blockande

InactiveCN1358401AAvoid lostProtect hearing abilityIntra aural earpiecesDeaf-aid setsInterior spaceHigh intensity

The present invention is to provide an earphone without impulse noise and surrounding blockade consists of an earphone housing having a sound chamber inside thereof and a loudspeaker mounted therein, wherein a plurality of sound outlet meshes is mounted in the front end of the earphone housing, and a proper distance is given between the front end of the earphone housing and the loudspeaker mounted therein, wherein a plurality of sound inlet meshes is mounted on and encircling the earphone housing within the proper distance; and the lower impulse noise output end according to two output ends of the loudspeaker is faced to the sound outlet meshes; via the design. The present invention can prevent not only the impulse noise directly impact to the middle ear but also the damage of the middle ear and the cause of conductive hearing loss.

Owner:COTRON

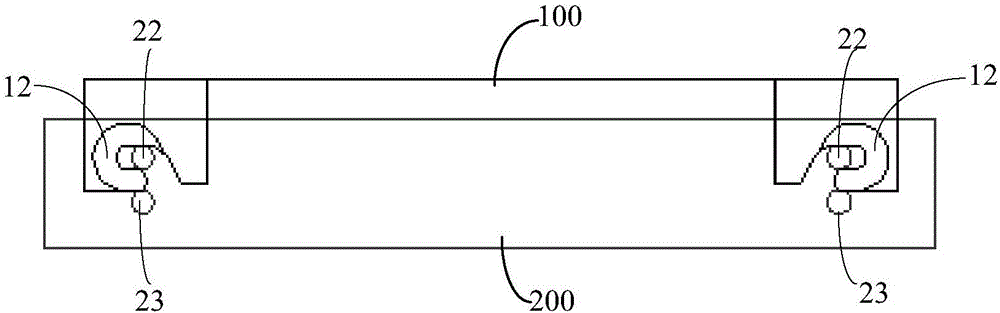

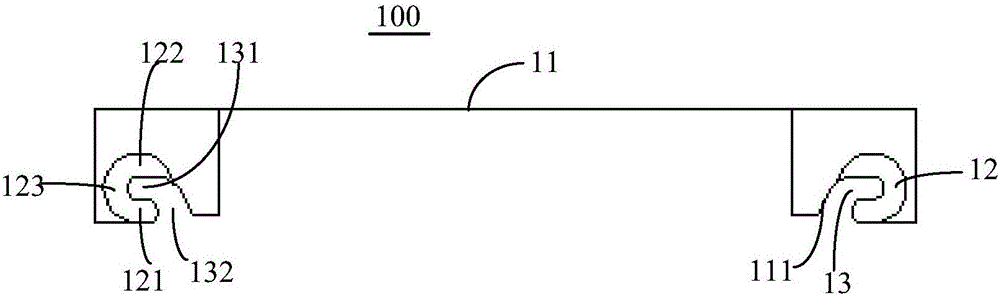

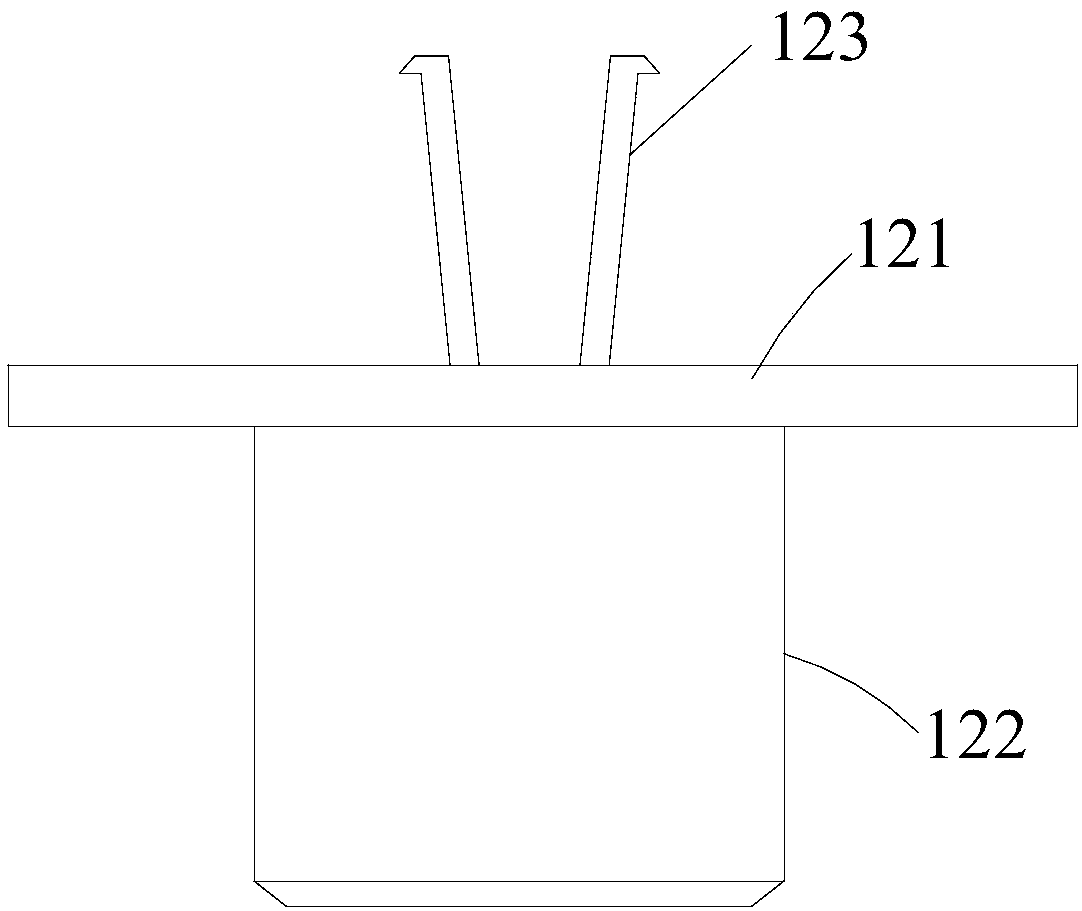

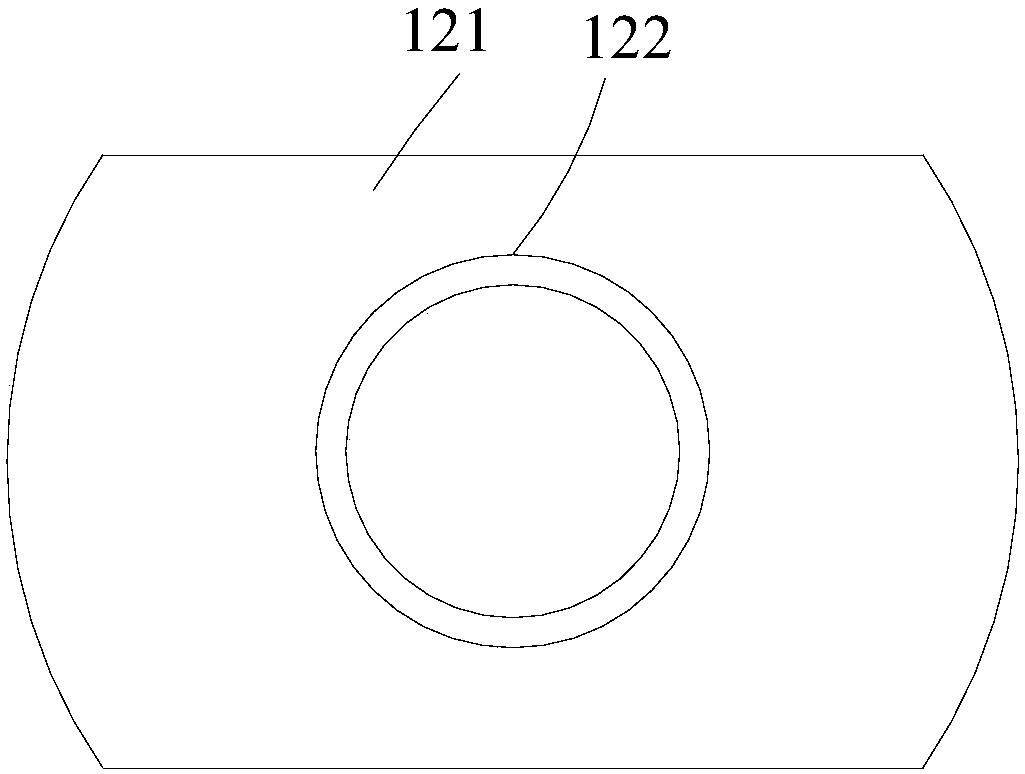

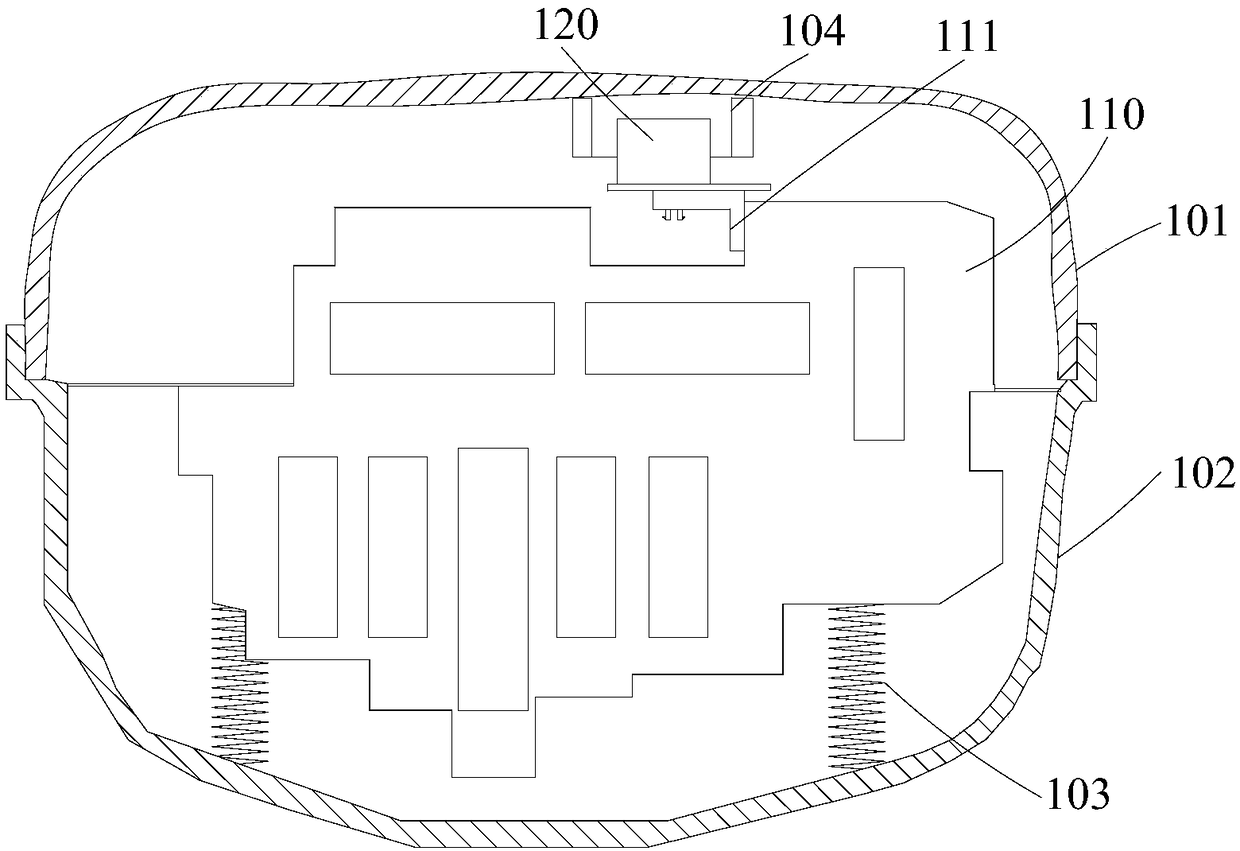

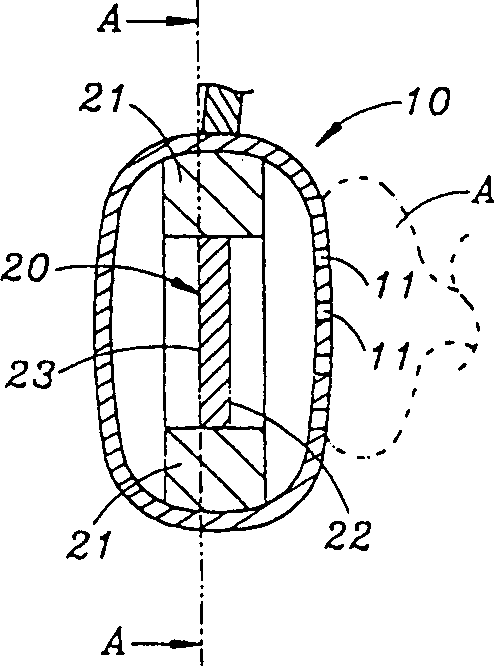

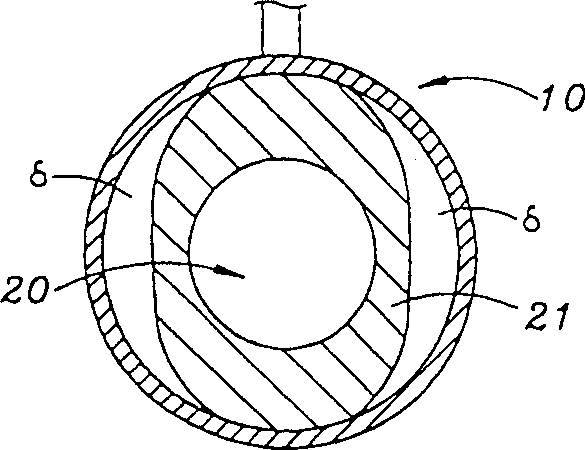

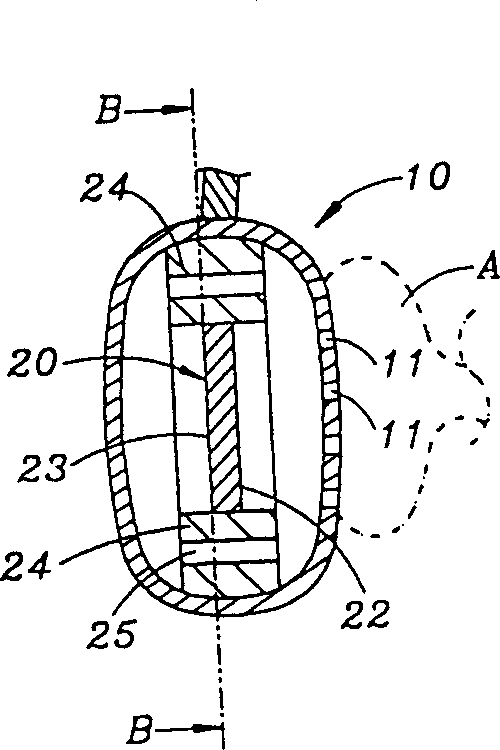

Caliper brake for elevator installations

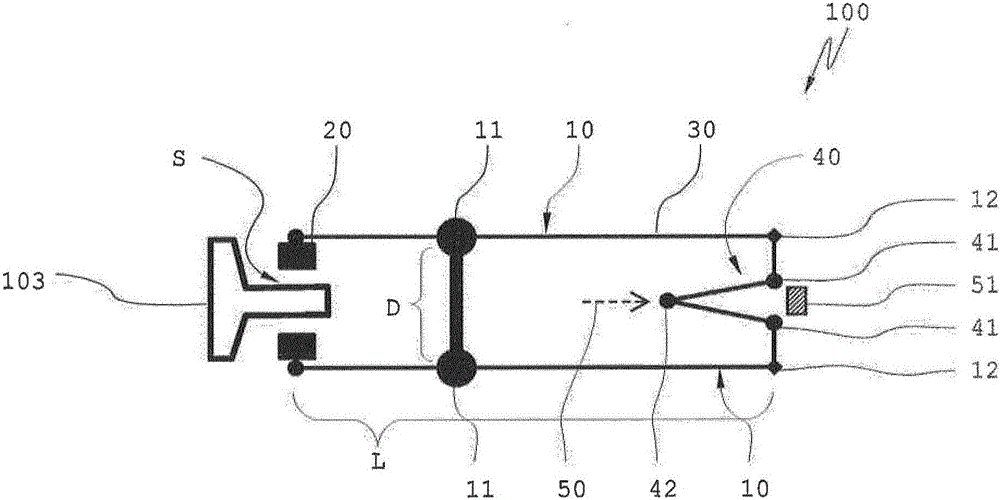

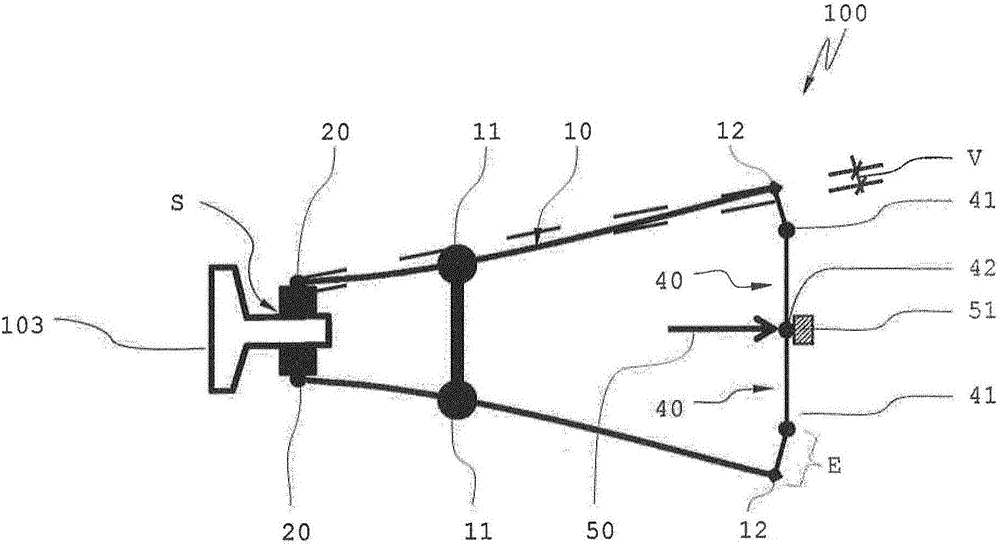

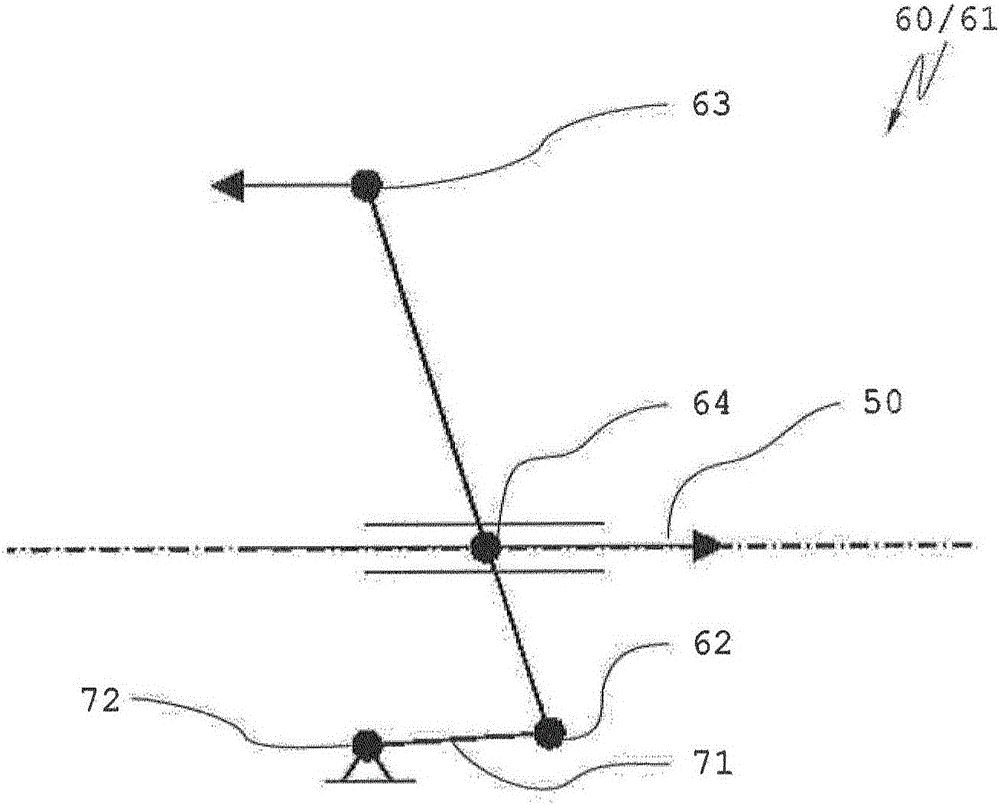

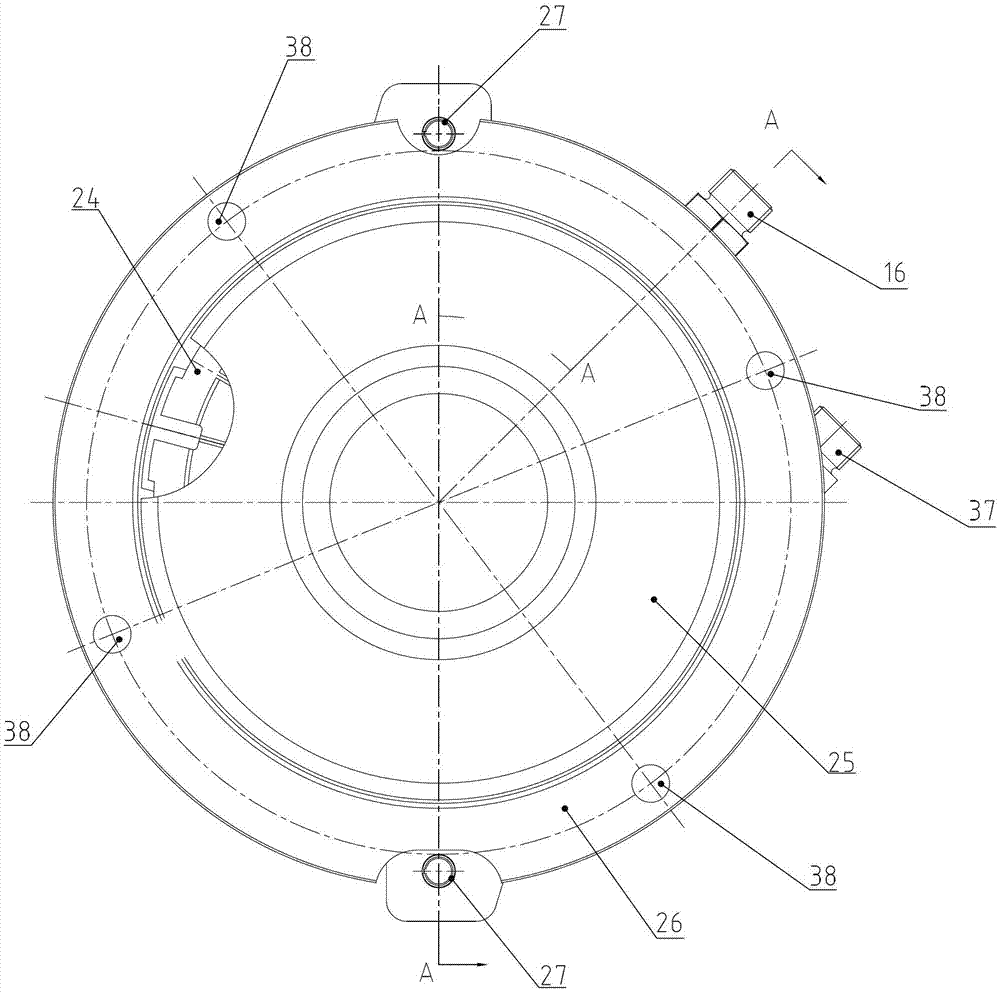

The invention relates to a caliper brake (100) for elevator installations, comprising at least one and preferably two brake calipers (10). Each brake caliper comprises at least one brake pad (20) and a brake arm (30) as well as a fulcrum (11). At least one brake caliper can be pivoted in at least one stand-by position and in a braking position. At least one brake arm (30) is resilient and is preferably at least partly designed as a leaf spring.

Owner:INVENTIO AG

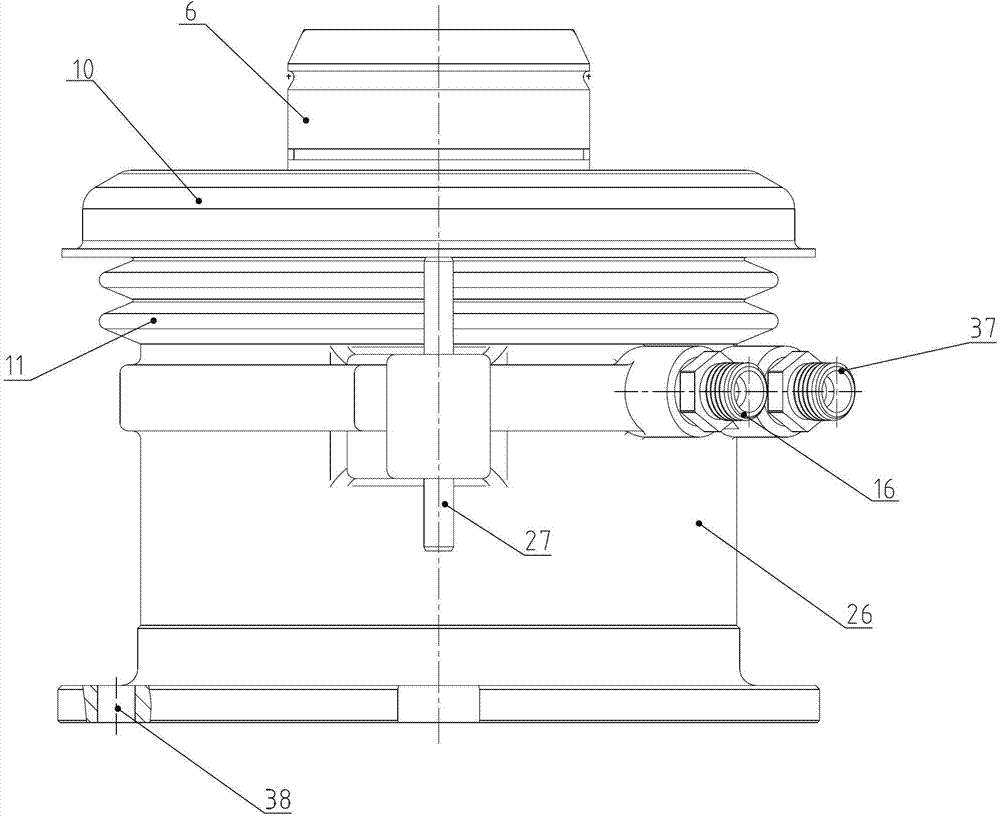

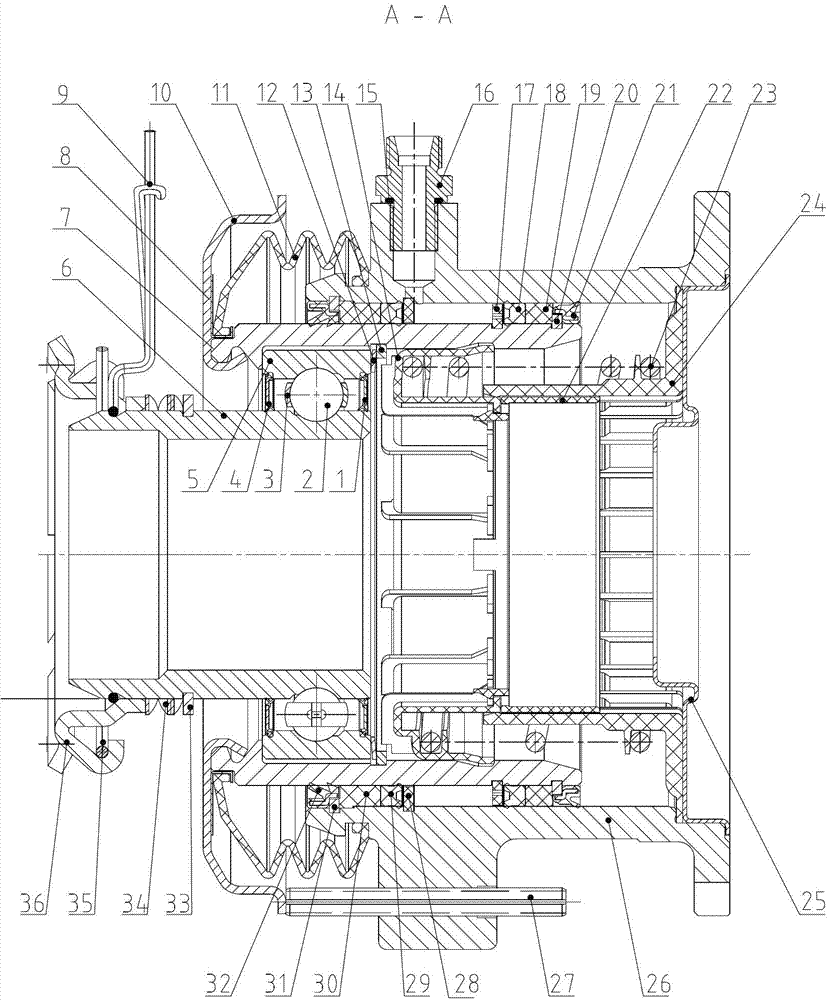

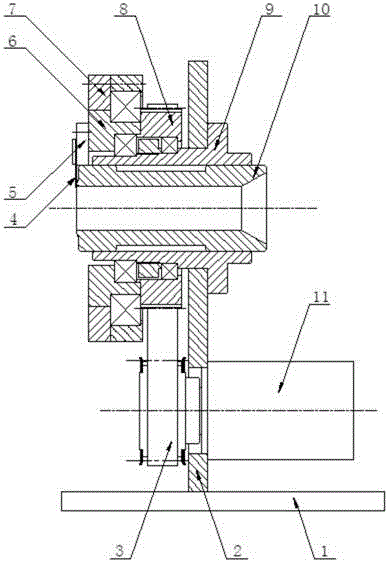

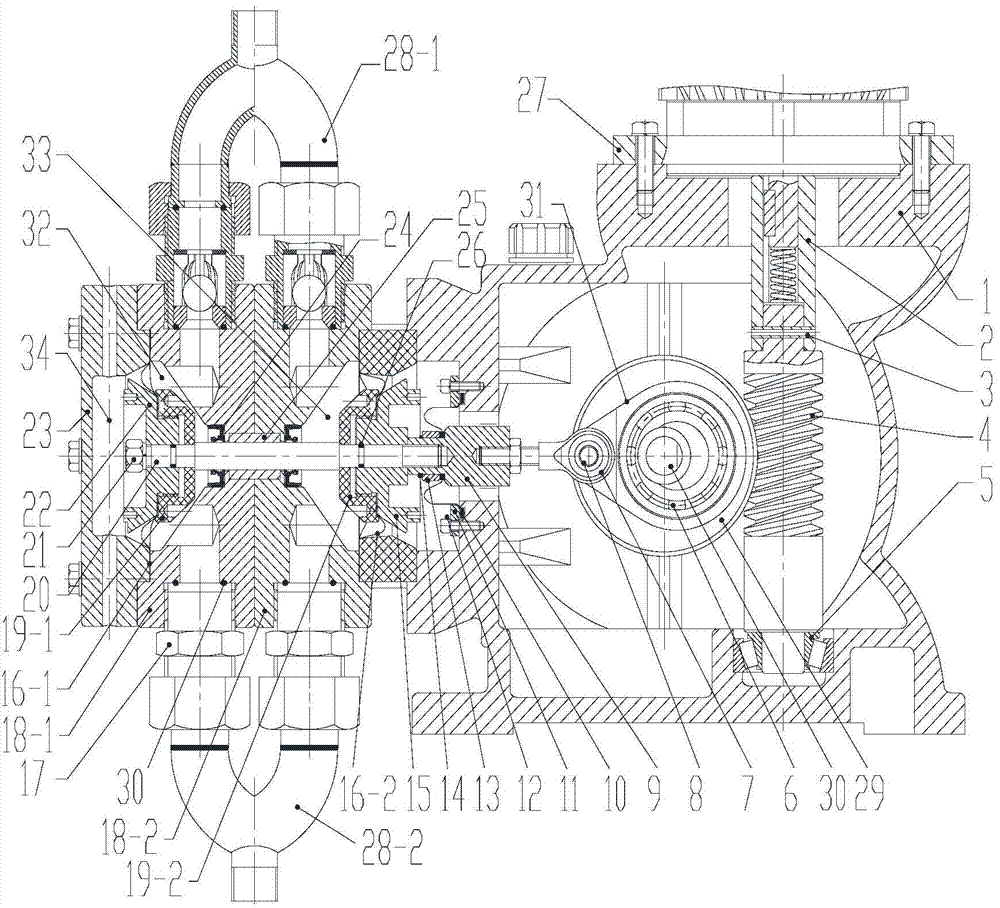

Hydraulic pressure automodulation pulling-type clutch release bearing assembly

ActiveCN103174770ASimple structureCompact structureFluid actuated clutchesBearing componentsPiston ringEngineering

The invention relates to a hydraulic pressure automodulation pulling-type clutch release bearing assembly, in particular to a pulling-type clutch release bearing assembly used for medium heavy-duty cars, and belongs to the technical field of an automobile clutch. The pulling-type clutch release bearing assembly comprises a piston and a cylinder body. A cylinder body dustproof sealing ring, a cylinder body snap ring, a cylinder body plastic space ring, a cylinder body hydraulic pressure sealing ring and a cylinder body ring are sequentially installed on an inner circle surface of the left end of the cylinder body from left to right. A piston dustproof sealing ring, a piston snap ring, a piston plastic space ring, a piston hydraulic pressure sealing ring and a piston ring are sequentially placed on an outer circle surface of the right end of the piston from right to left. The pulling-type clutch release bearing assembly is simple, compact and reasonable in structure, abrasion-free, impact noise-free, stable in separating, good in operation and convenient to shift, and speed can be changed conveniently.

Owner:WUXI MINLIAN AUTOMOBILE PARTS CO LTD

Automatic hose cutting-off device

The invention provides an automatic hose cutting-off device. The automatic hose cutting-off device comprises a support frame, a transmission mechanism, a guide mechanism and a cutting-off mechanism; the support frame comprises a supporting plate and a fixed sleeve penetrating through the supporting plate; the transmission mechanism comprises an inner moving coil rotatably sleeving the fixed sleeve and an outer moving coil rotatably sleeving the inner moving coil; the inner moving coil drives the outer moving coil to rotate together by use of a limiting bump fixedly arranged on the inner moving coil; the guide mechanism is fixedly arranged on the outer moving coil and comprises a guide slider; the cutting-off mechanism comprises a blade holder, and a blade fixedly arranged on the blade holder; one end of the blade holder is arranged on and hinged to the inner moving coil and used for enabling the blade to cut a hose back and forth in the radial direction. The automatic hose cutting-off device is capable of eliminating bumping noise while cutting the hose and protecting the hose against deformation during continuous cutting, and applicable to cutting the hoses of various diameters.

Owner:南通市通州区三槐机械制造有限公司

Leftward and rightward door opening mechanism and refrigerator

ActiveCN106016927AOpen smoothlyClose smoothlyLighting and heating apparatusHingesRefrigerator carGear drive

Owner:HAIER SMART HOME CO LTD

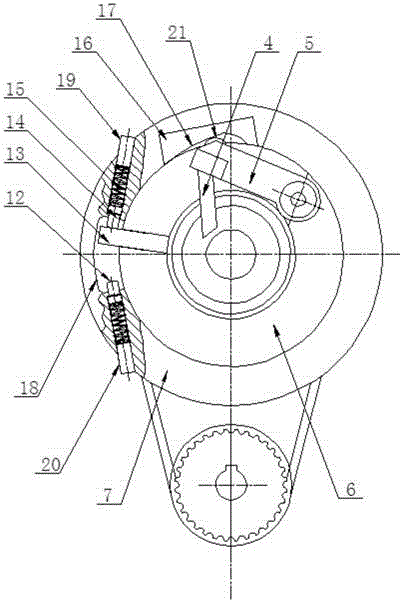

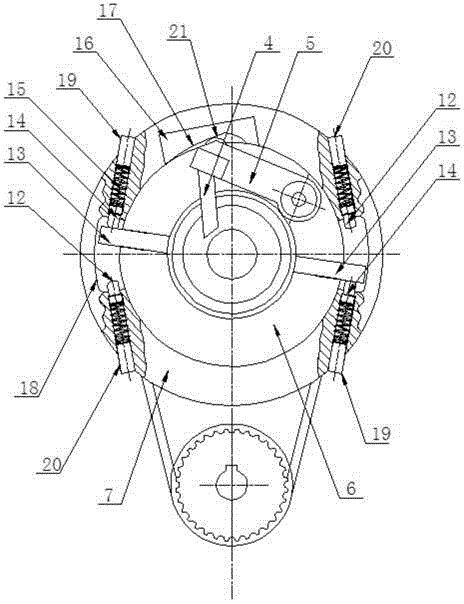

Slide-block type reversing clutch

InactiveCN101639102AGood mechanical fitLarge torque transmissionFreewheel clutchesDrive shaftEngineering

The invention relates to a slide-block type reversing clutch mainly consisting of a left transmission wheel, a left transmission wheel, a bush and slide block components. The left transmission wheel and the right transmission wheel are supported on the bush by bearings. The slide block components are radially assembled on the bush in a sliding manner and positioned inside rims of the left transmission wheel and the right transmission wheel. Inner walls of the rims of the transmission wheels are provided with unidirectional progressive sliding grooves which can be form pallet tennon transmission fit by alternating with the slide block components. Only the change of the rotation direction of a driving shaft can realize transmission clutch switch so as to alternately drive the left transmission wheel or the right transmission wheel to rotate. The slide-block type reversing clutch can bear and transfer great power by using the slide block components as transmission clutch parts, and avoidthe phenomenon of transmission slip or seizure. The invention has the remarkable advantages of stable transmission fit, light and flexible reversing separation and no collision noise during clutchingoperation, can prolong the service life of the clutch by folds and has a good market prospect.

Owner:代绍康

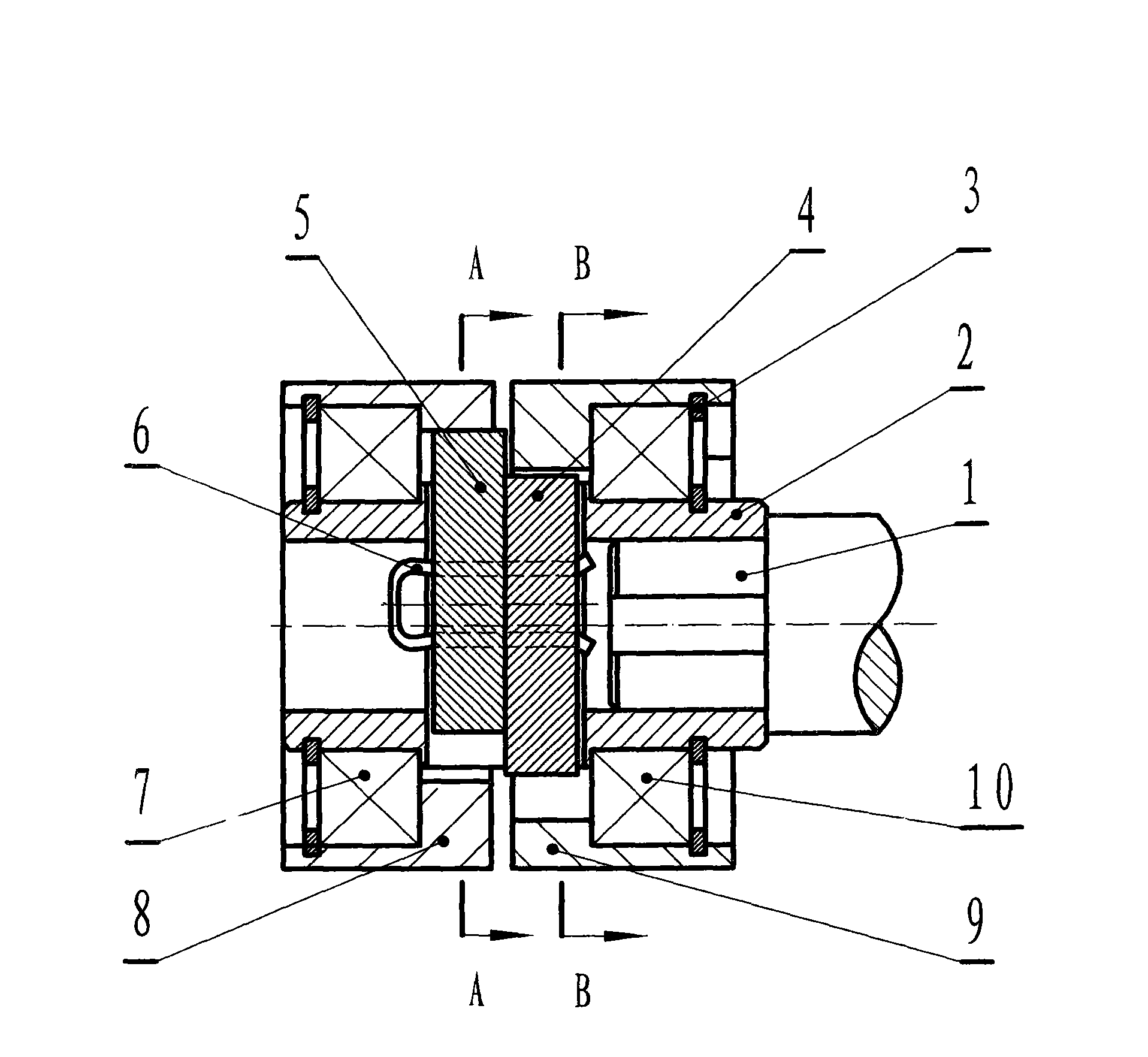

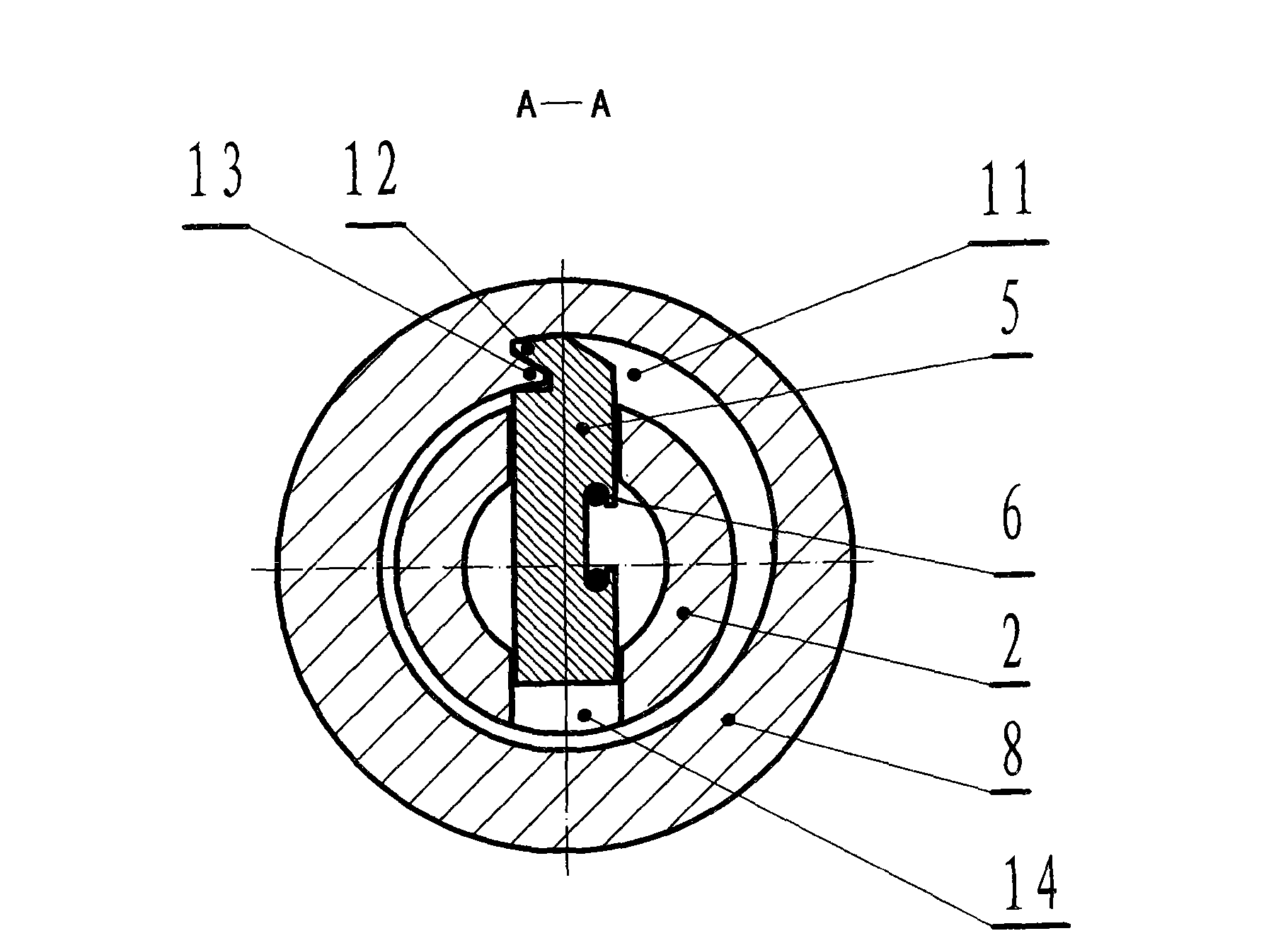

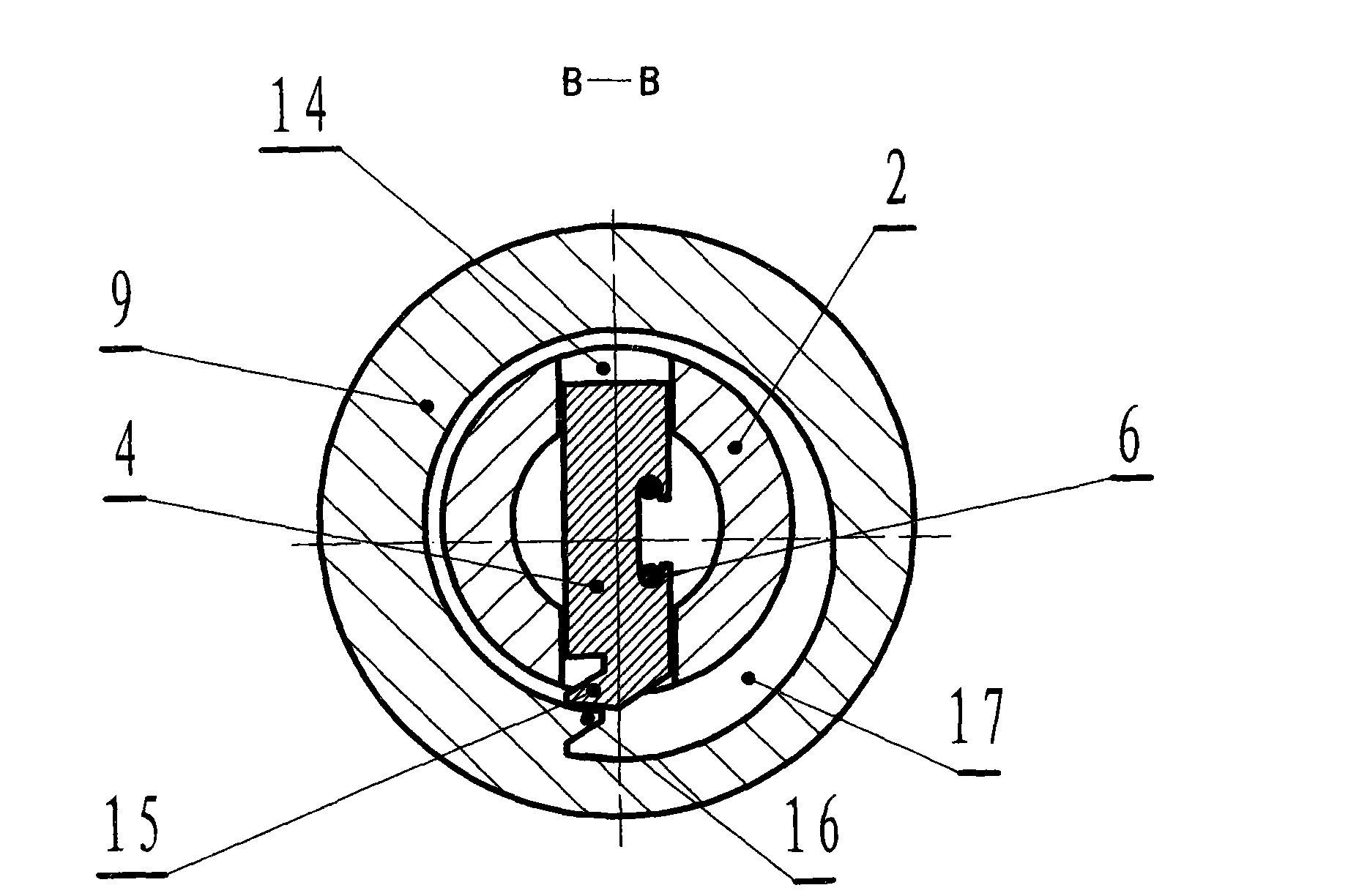

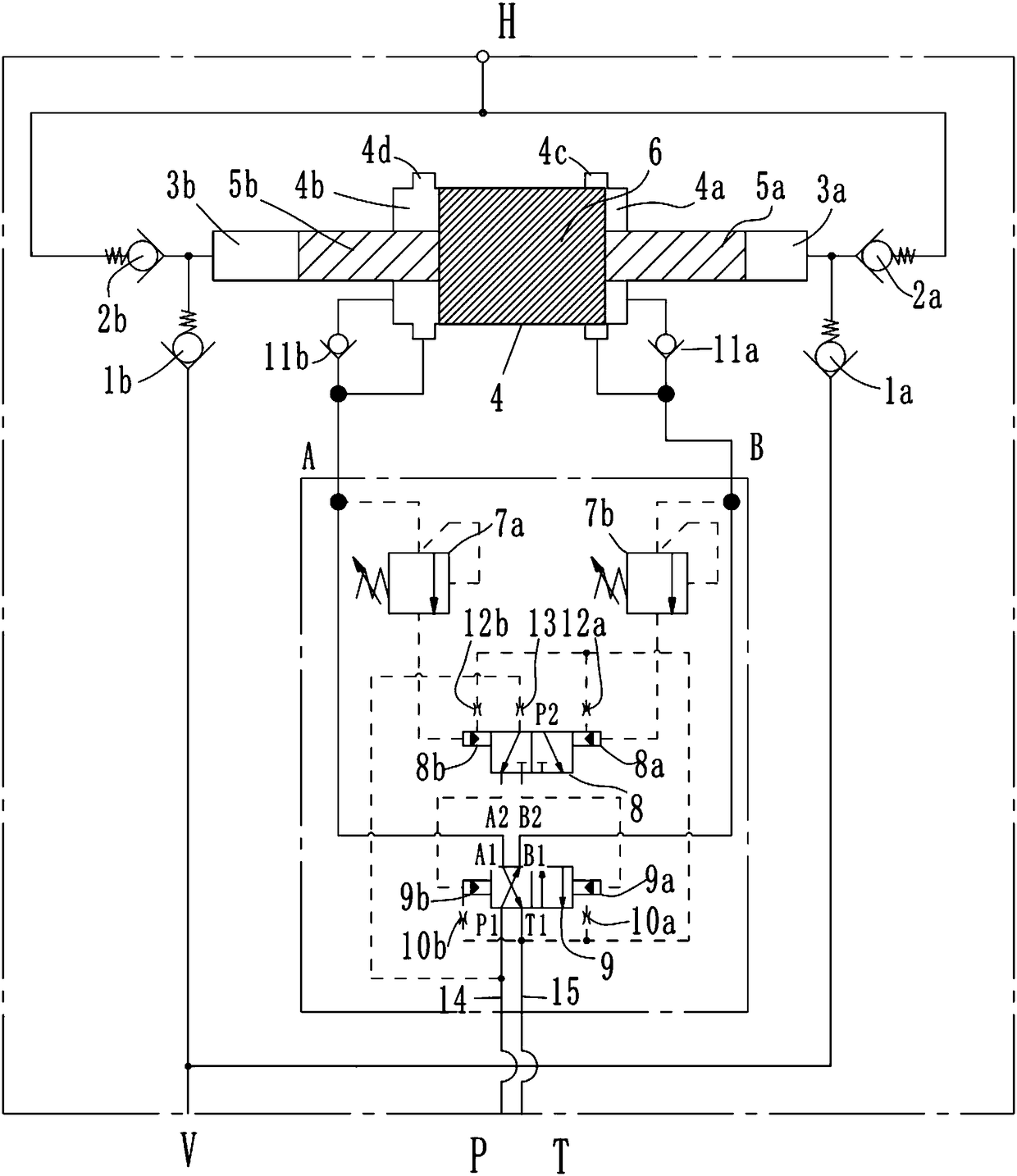

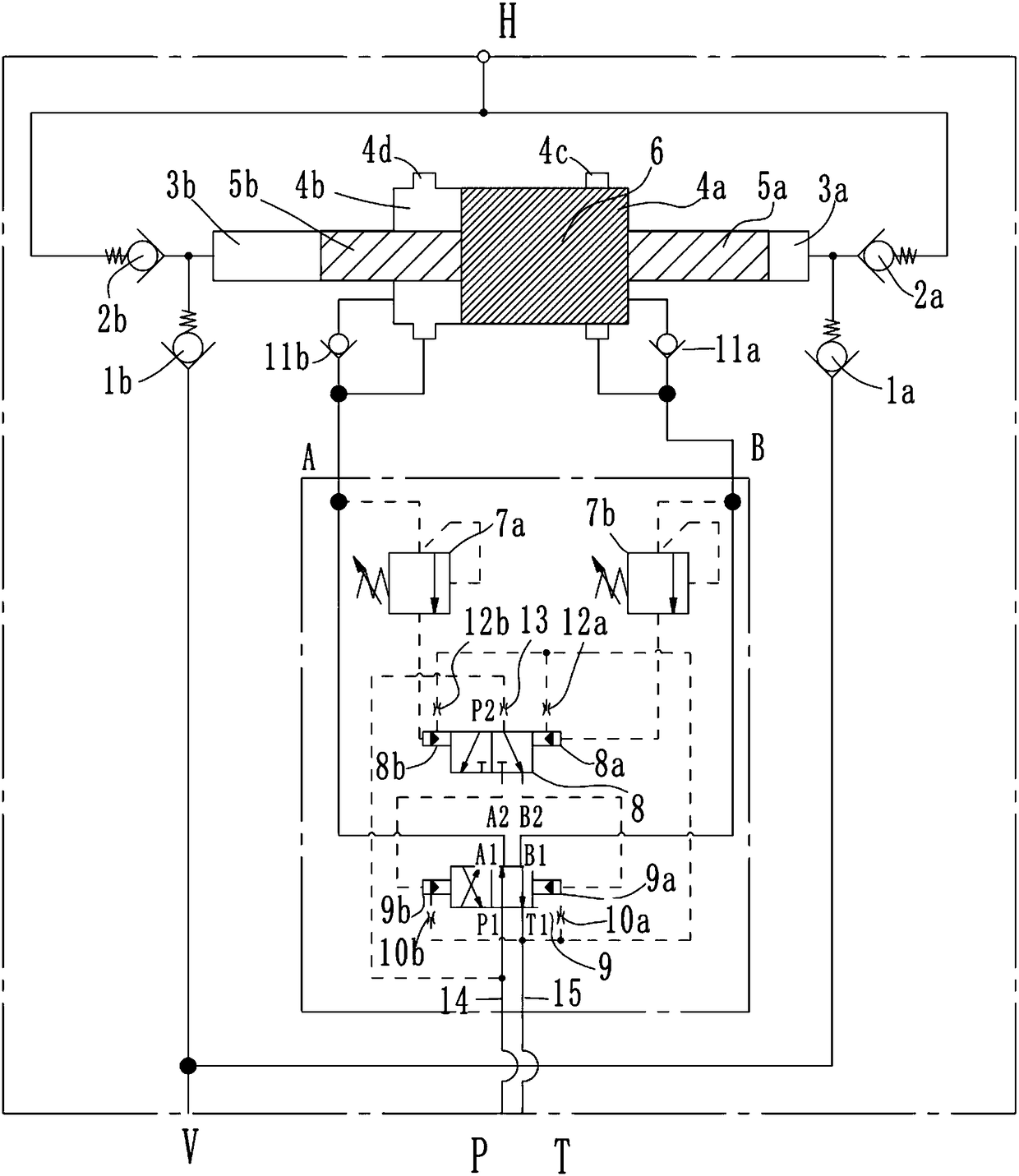

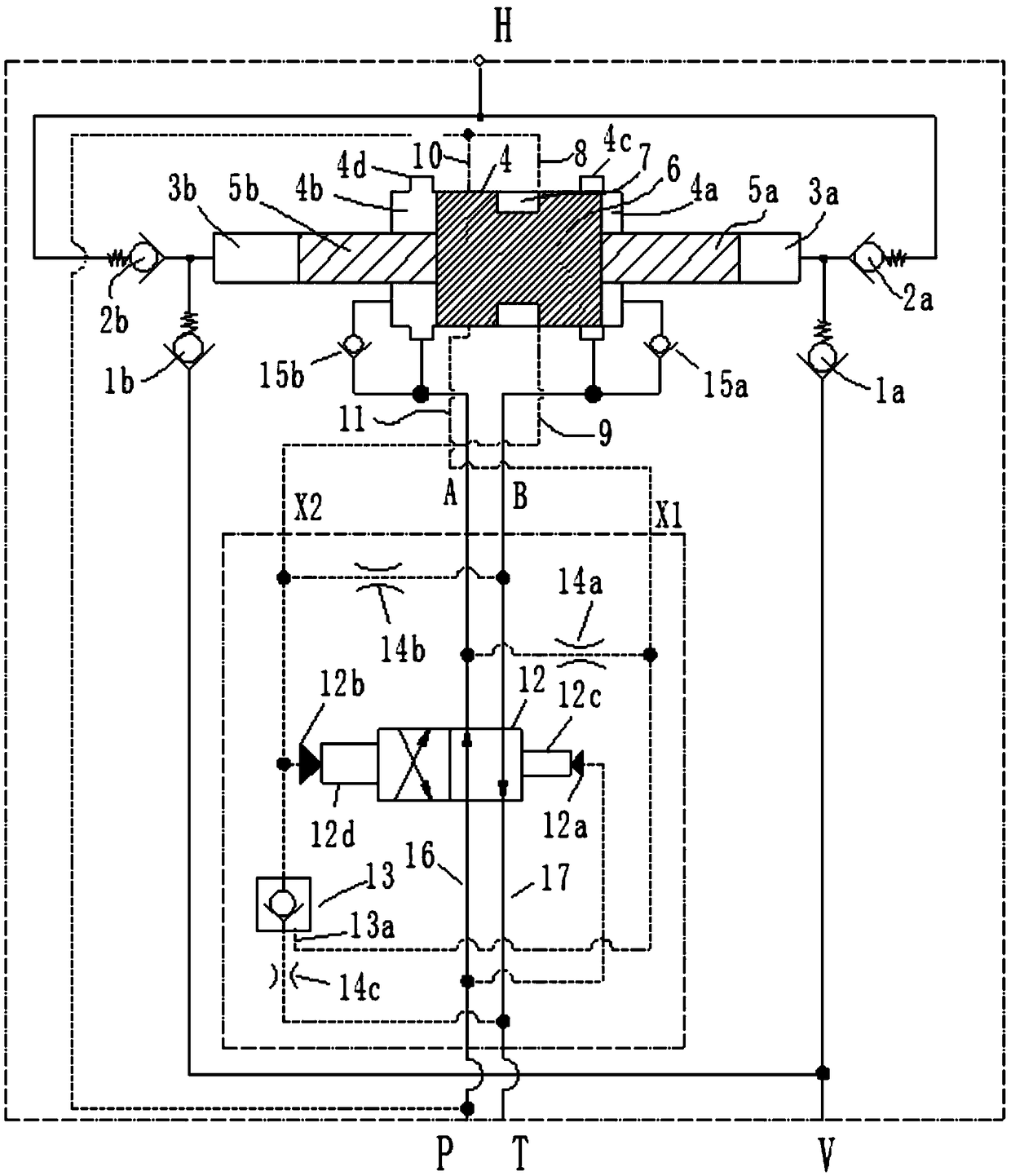

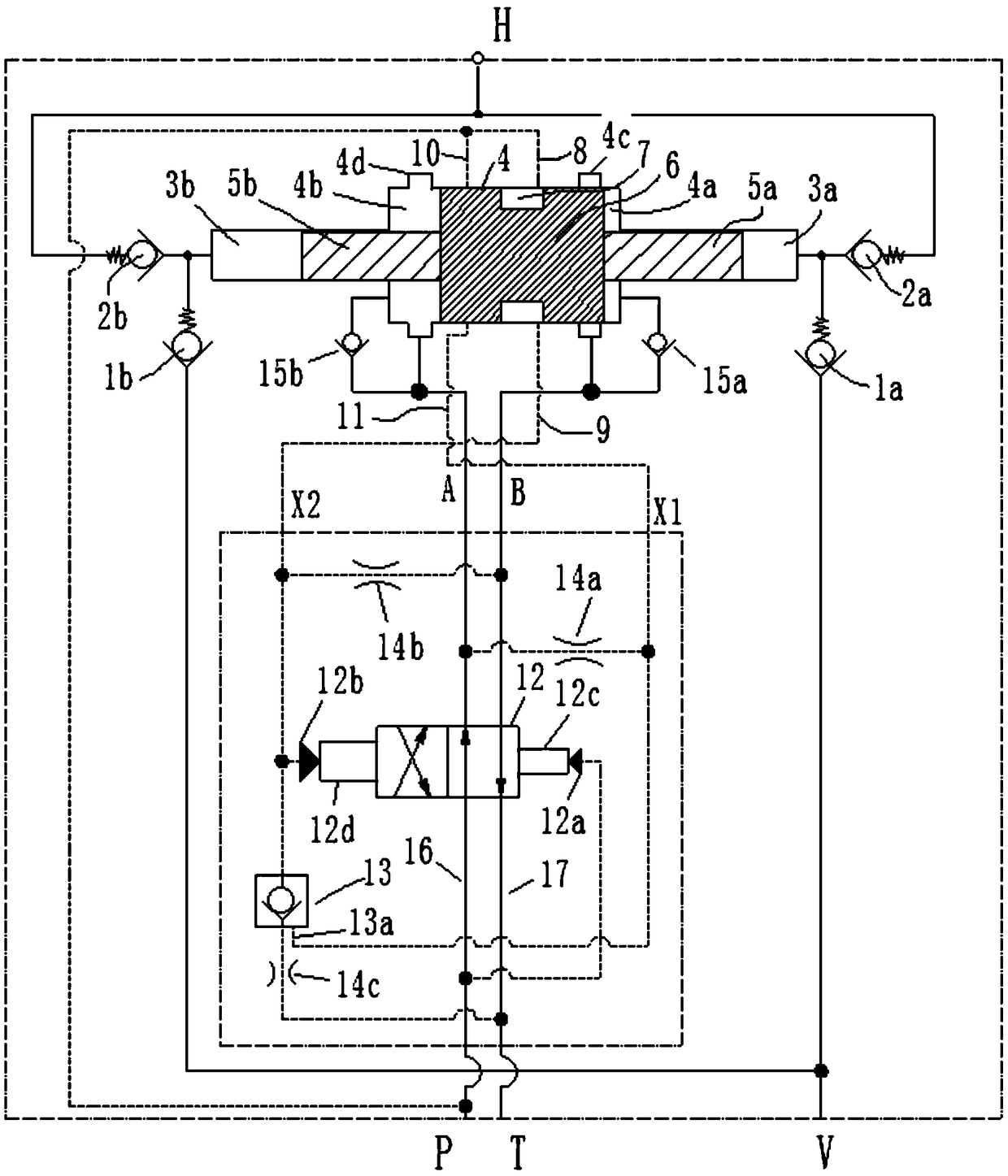

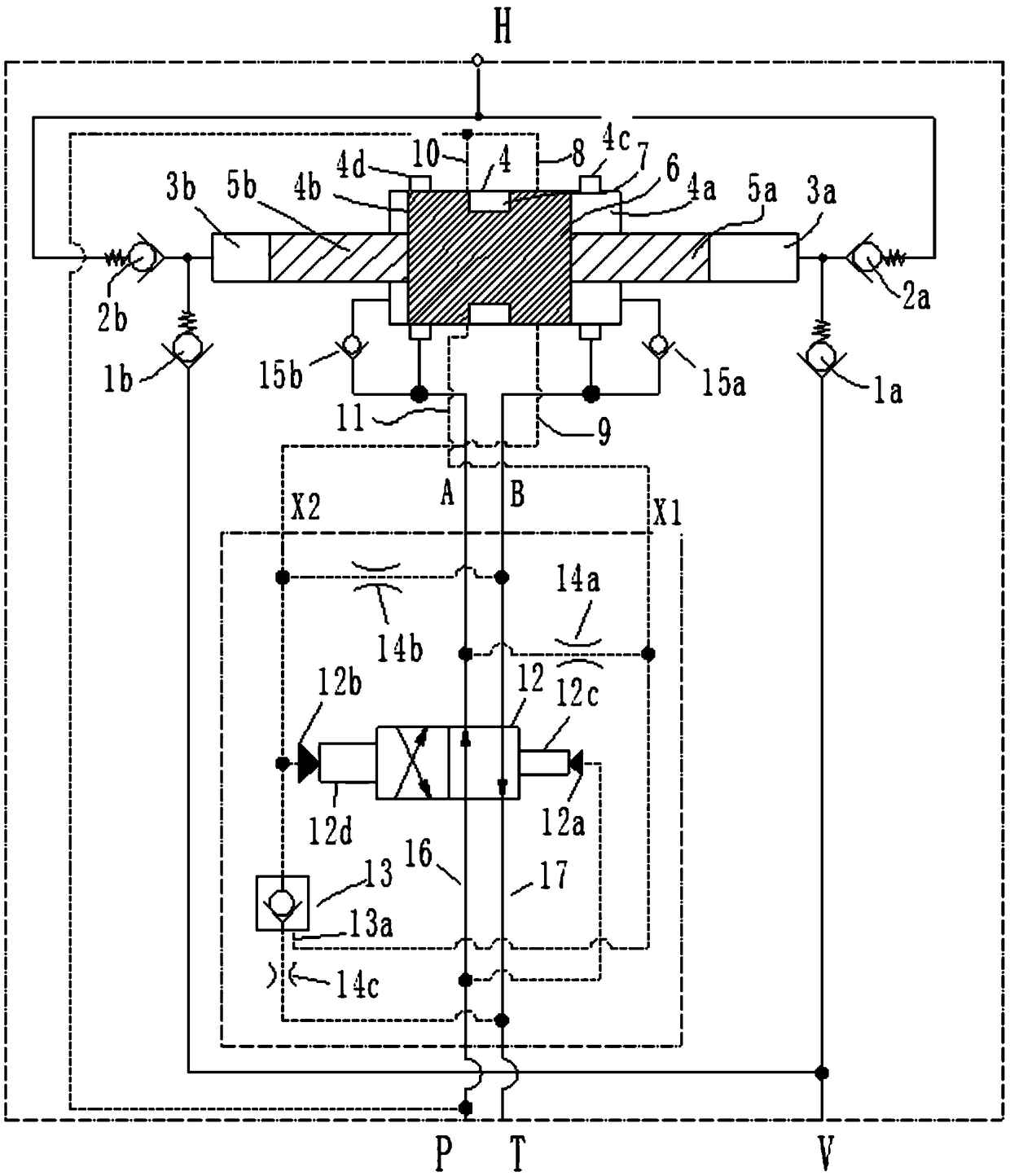

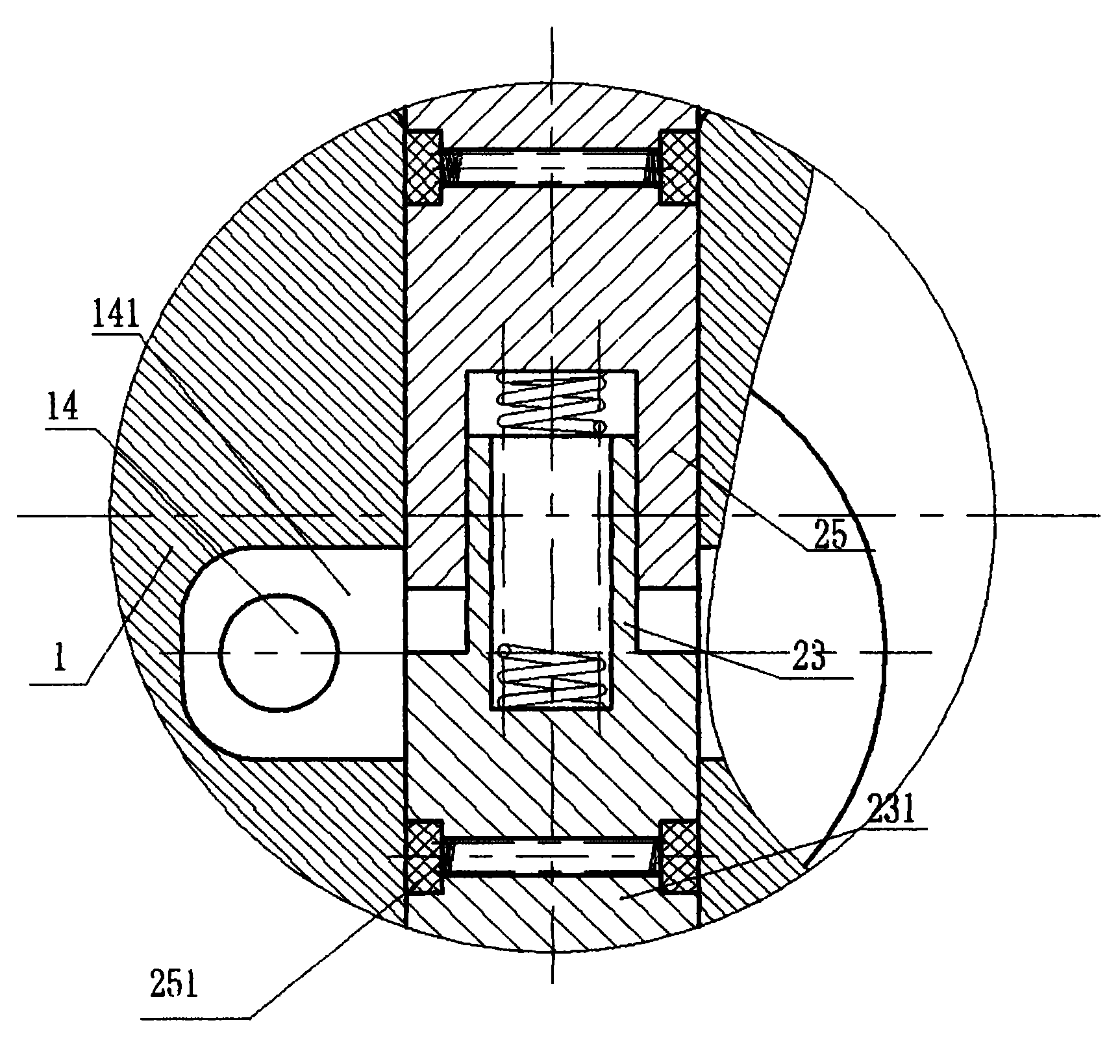

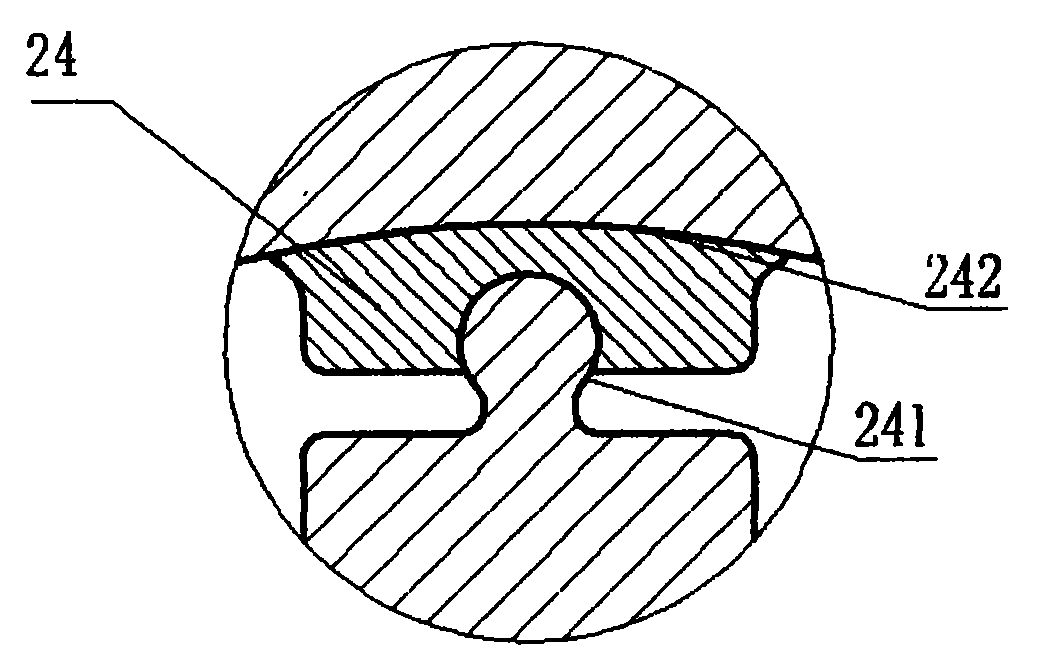

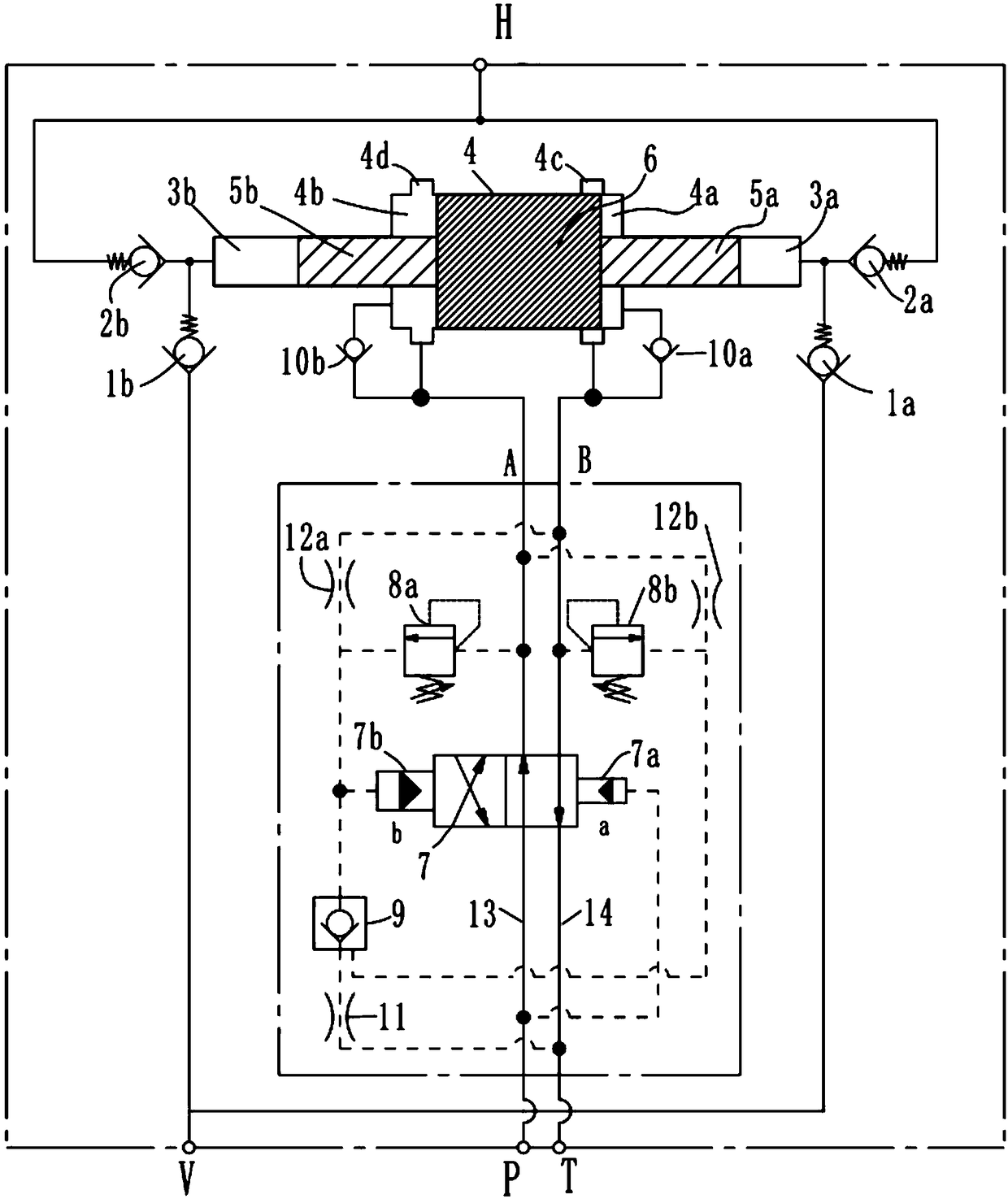

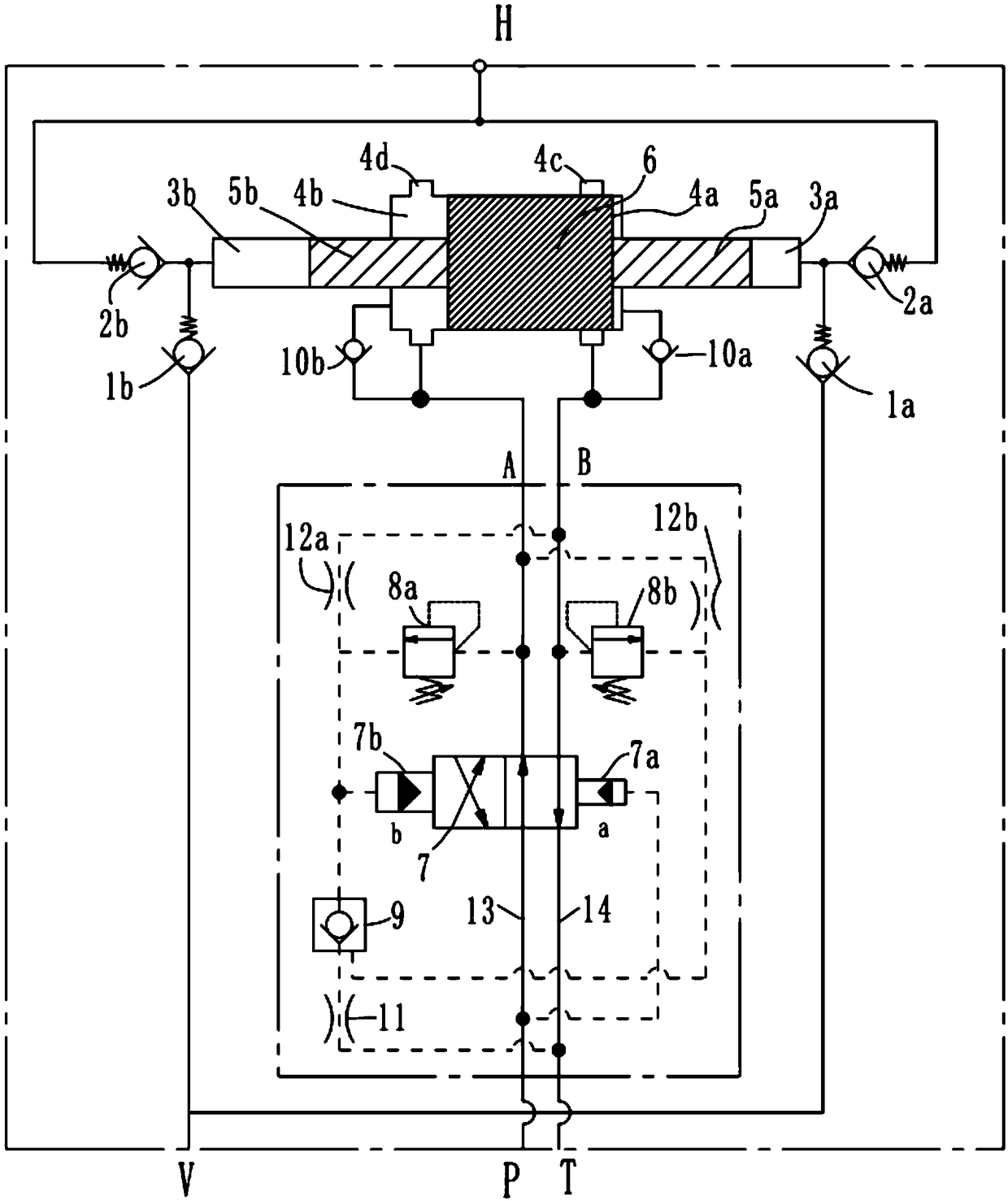

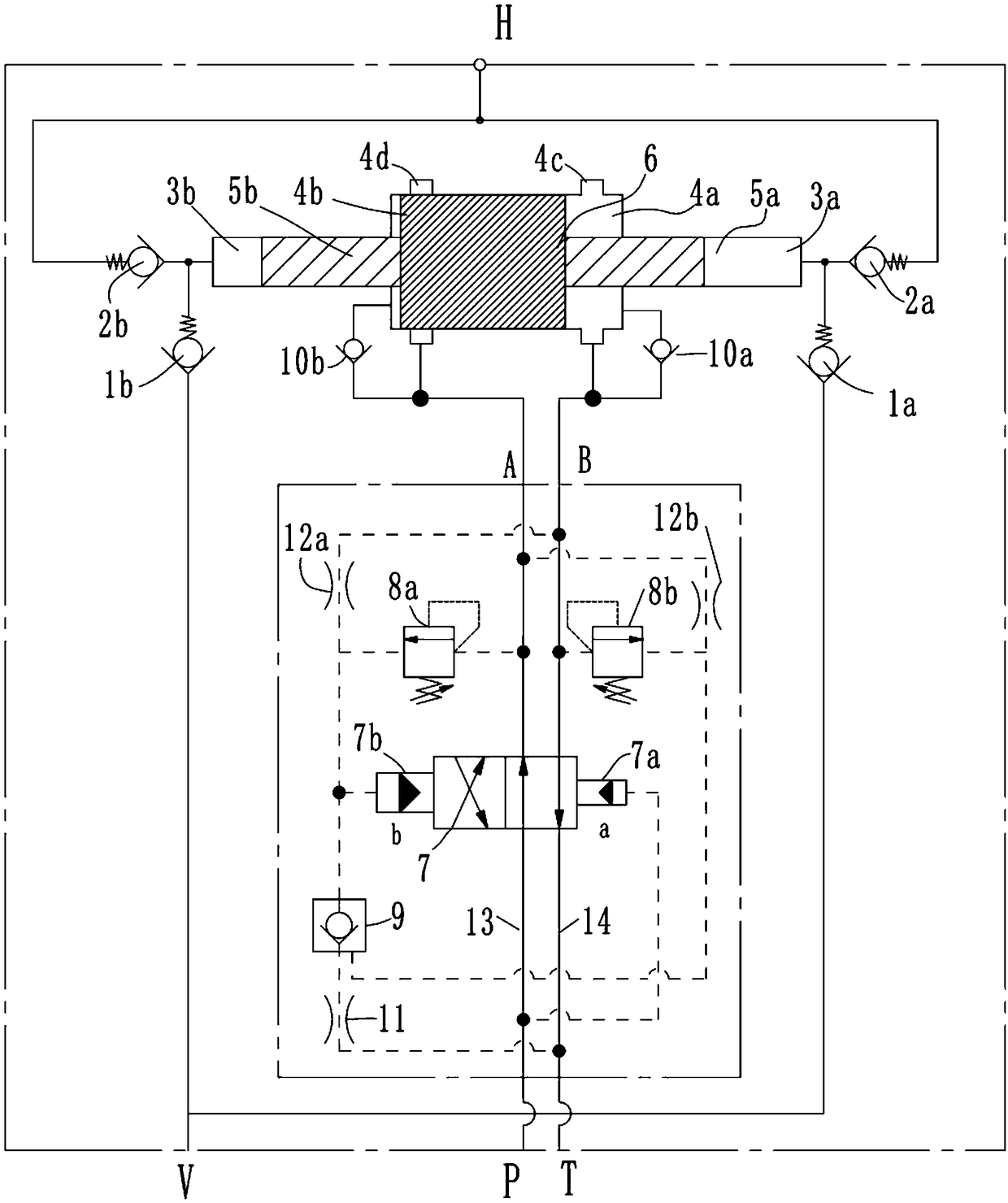

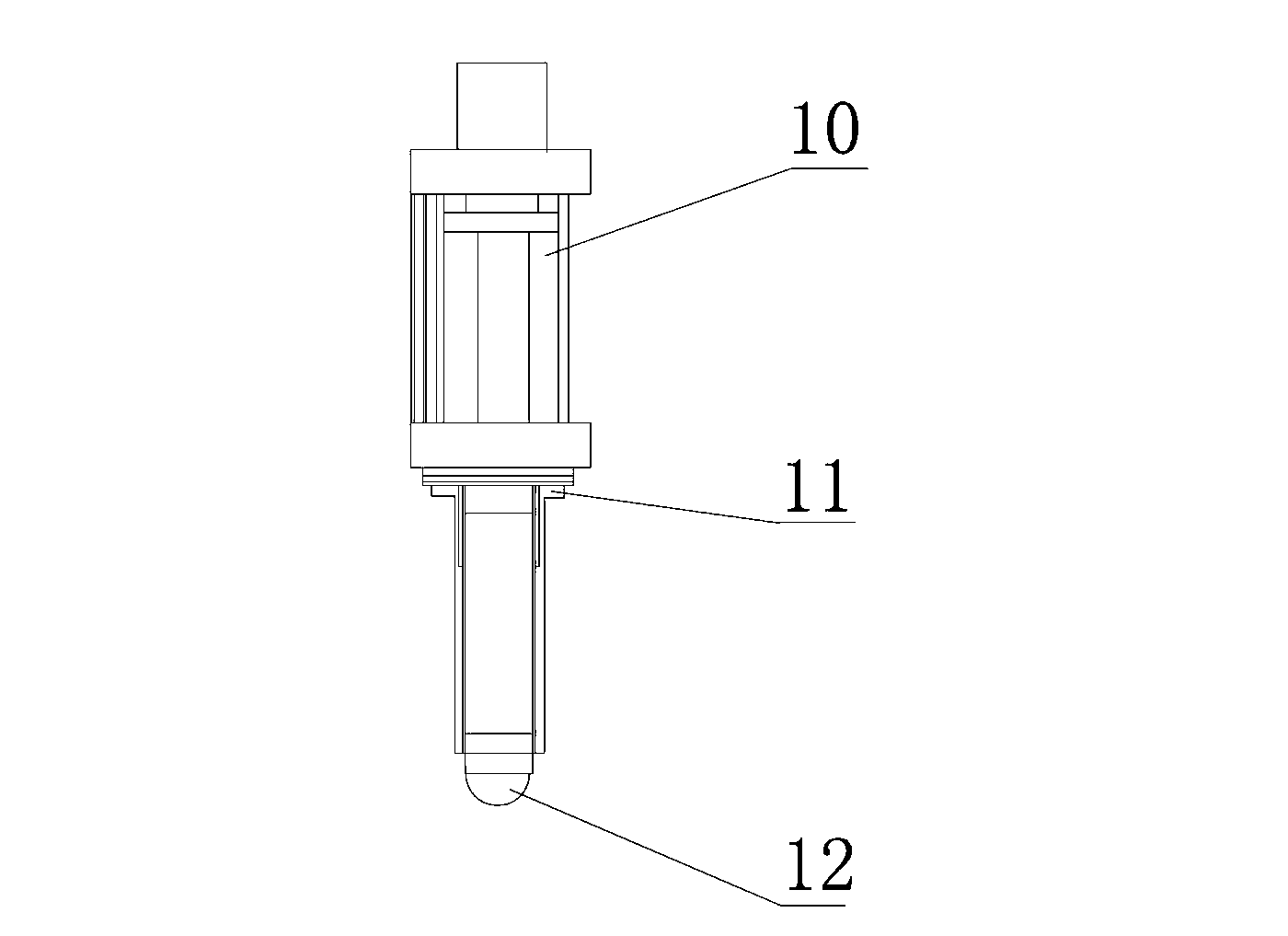

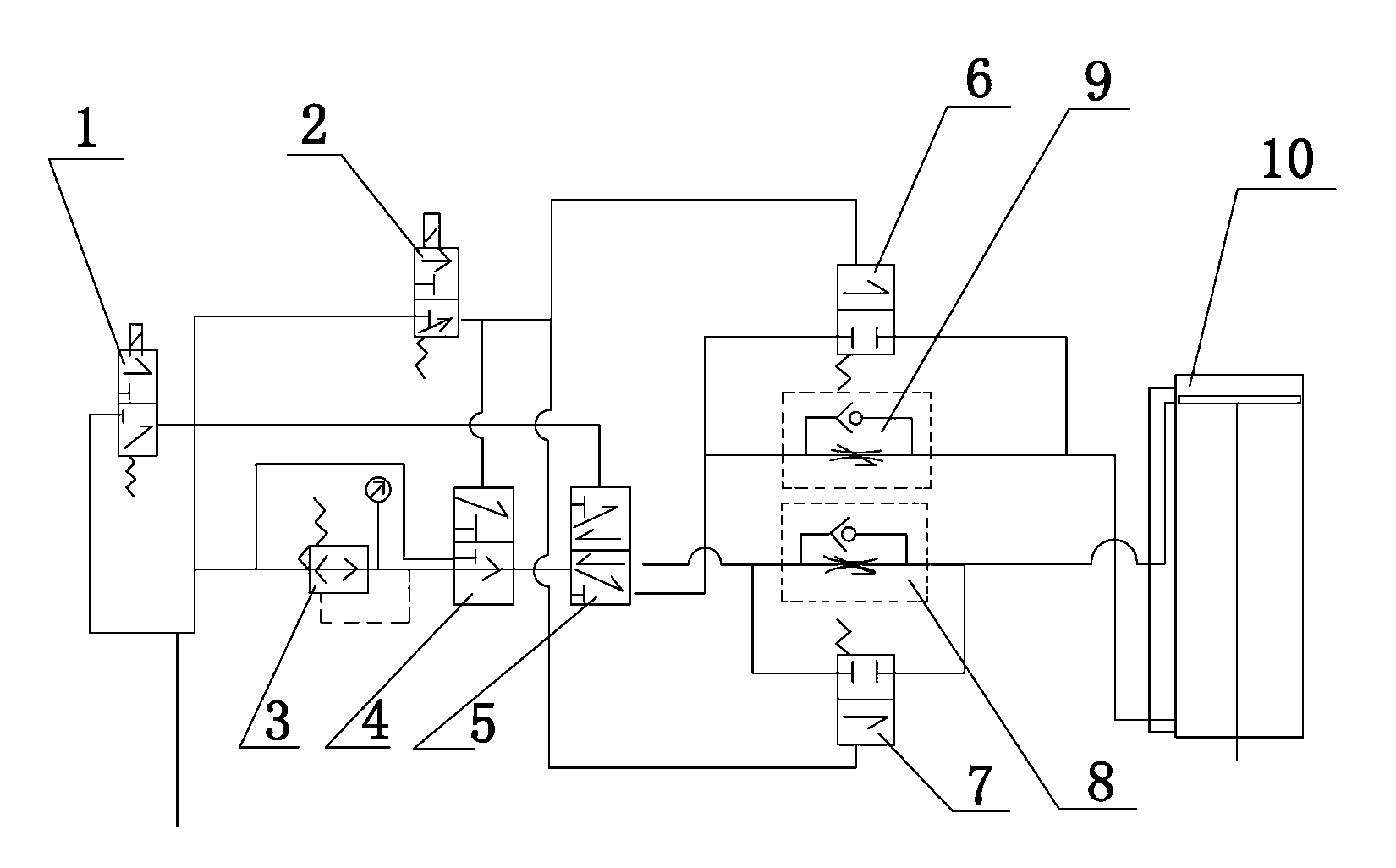

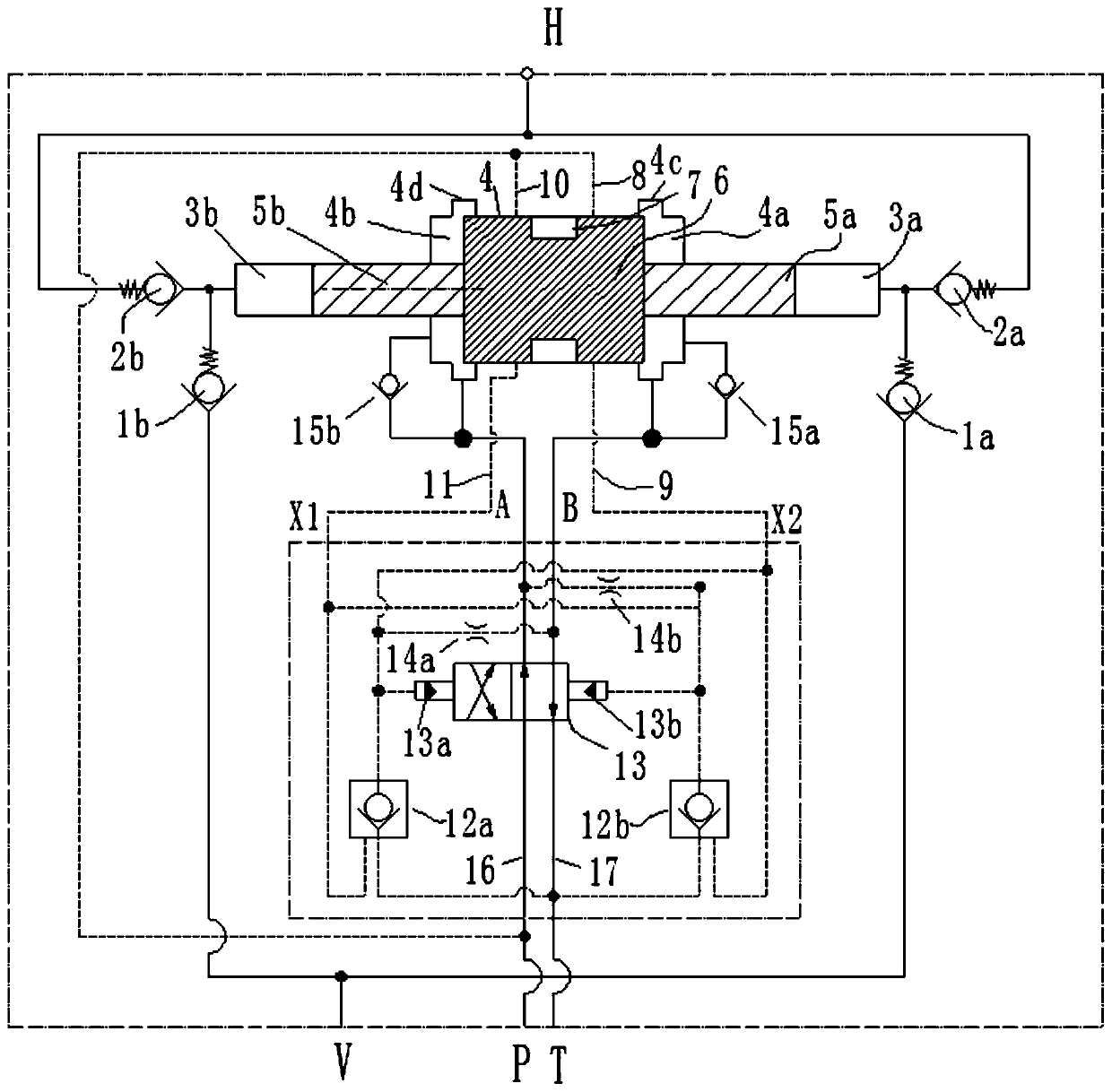

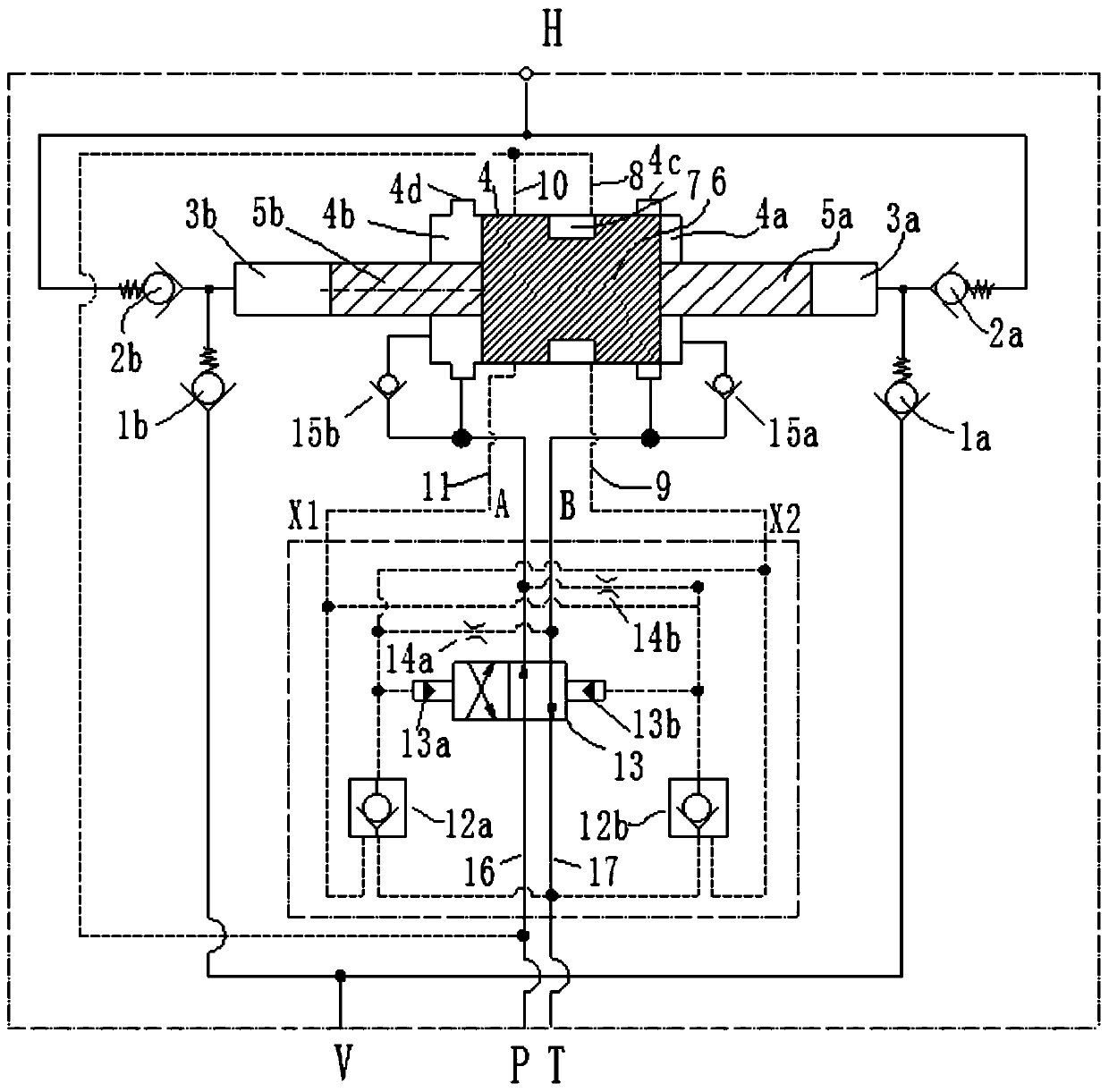

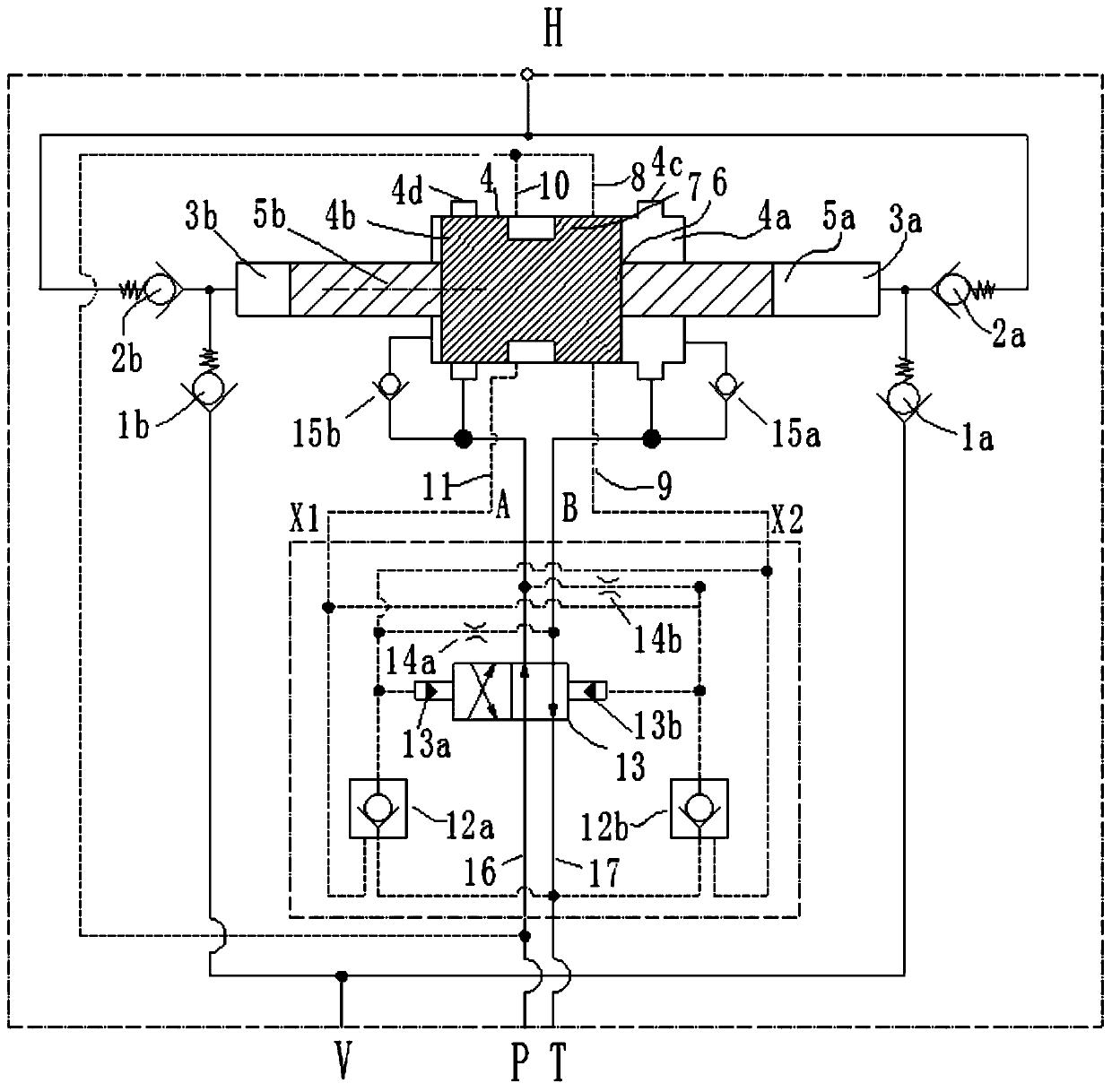

Hydraulic drive fracturing pump

ActiveCN108425665AAvoid collisionLow efficiencyPositive displacement pump componentsFluid removalLow noiseEngineering

The invention discloses a hydraulic drive fracturing pump. The pump is provided with an oil inlet P, an oil return port P, a liquid inlet V and a high pressure oil outlet H. The pump includes a pressure cylinder and a pilot operated directional control valve. The pressure cylinder includes a low pressure cylinder, a low pressure piston, a left high pressure plunger, a right high pressure plunger,a left high pressure cylinder and a right high pressure cylinder; when the low pressure piston moves left to the position where the low pressure piston fully covers a first through runner, the pilot operated directional control valve is triggered to reverse, and the low pressure piston is braked by a closed left piston cavity; when the low pressure piston moves right to the position where the lowpressure piston completely covers a second through runner, the pilot operated directional control valve is triggered to reverse, and the low pressure piston is braked by a closed right piston cavity;the fracturing pump has the advantages of simple structure, no need of electric control, and low noise.

Owner:阿奥艾斯能源科技成都有限公司

Left and right door opening mechanism and refrigerator

ActiveCN106766586AOpen smoothlyClose smoothlyLighting and heating apparatusCooling fluid circulationEngineeringRefrigerated temperature

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

Limiting structure for compressor

PendingCN108252899APrevent trip springAvoid knocking noisePositive displacement pump componentsPositive-displacement liquid enginesRefrigeration compressorEngineering

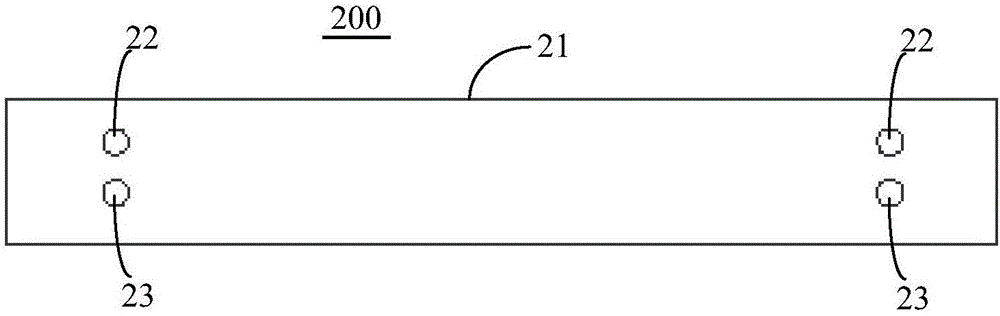

The invention provides a limiting structure for a compressor, belonging to the field of refrigeration compressors. The limiting structure comprises a shell and a machine core located in the shell, wherein a plurality of pressure springs are arranged between the machine core and the shell, a limiting pin is further arranged on the machine core, a limiting ring is arranged on the inner side of the shell, and the limiting pin is inserted into the limiting ring. The limiting structure has an all-dimensional limiting function, the release of the springs can be prevented, and the metal impact noisecan be prevented; and the limiting structure is simple and easy to assemble.

Owner:黄石东贝压缩机有限公司

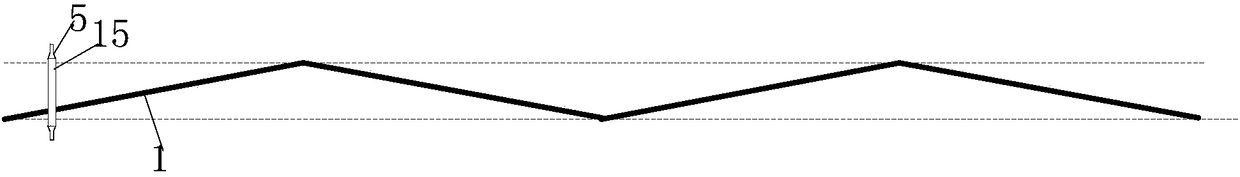

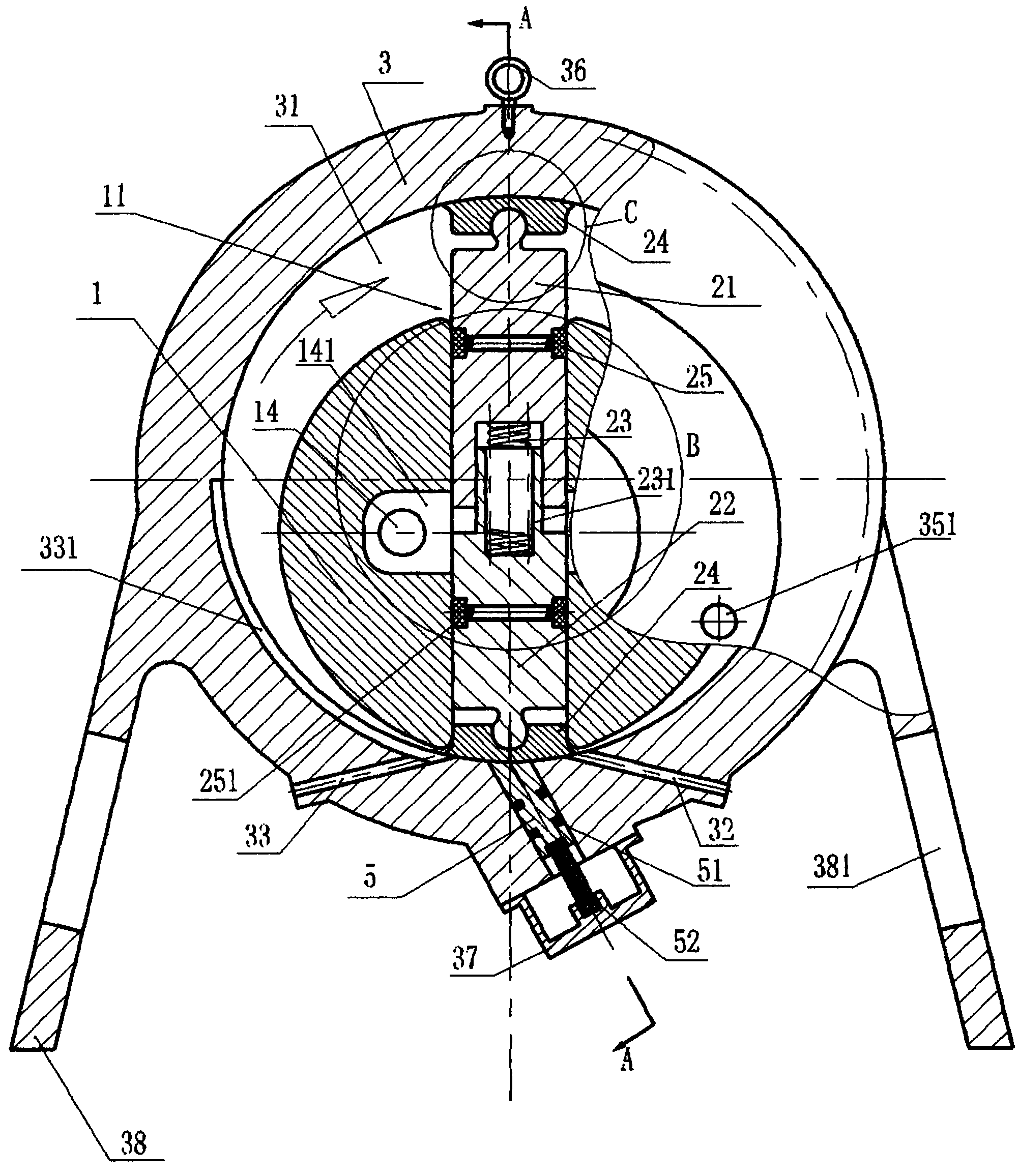

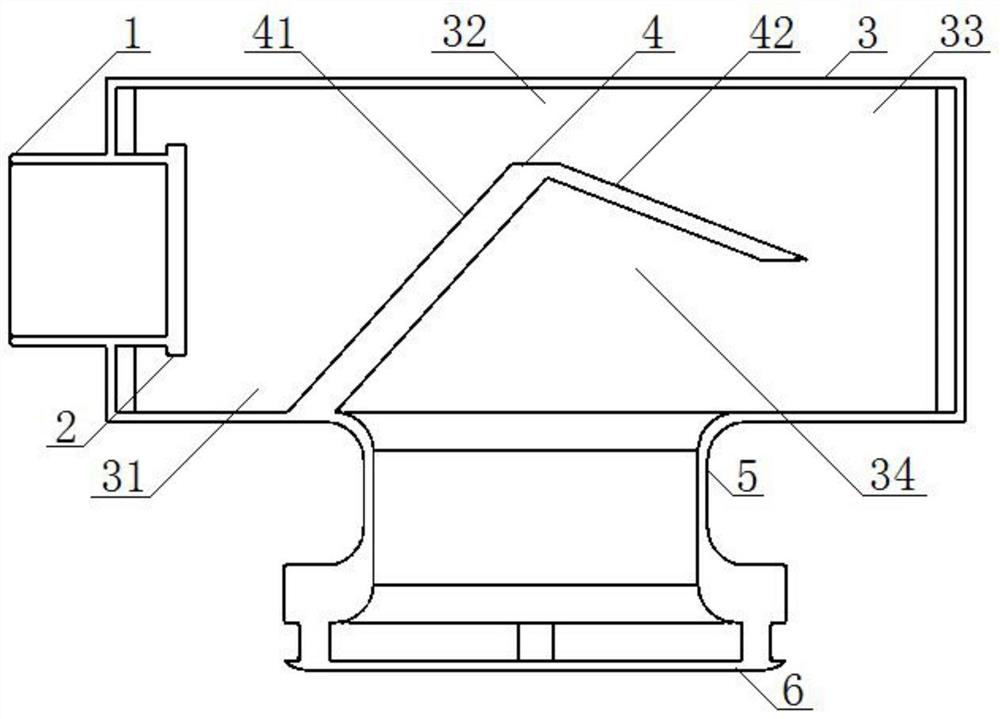

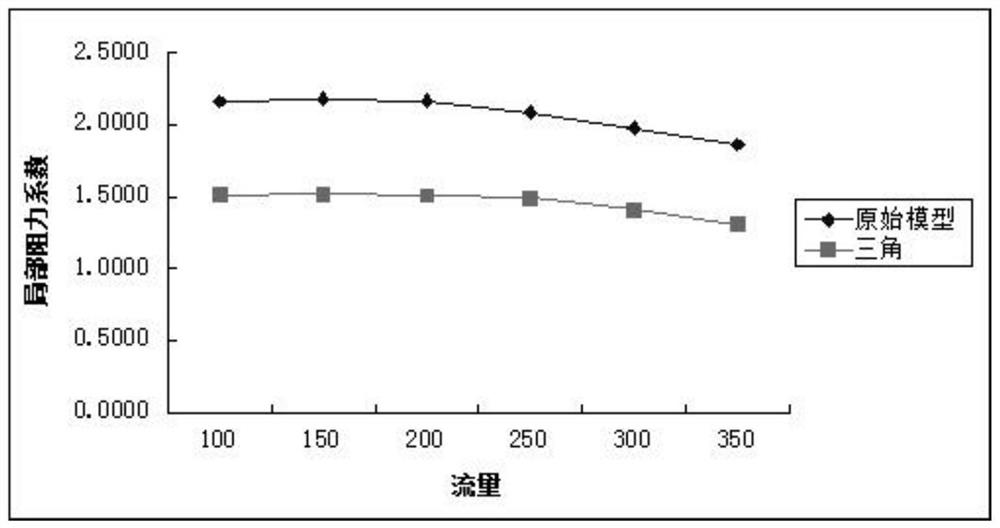

Low-noise current collecting system for medium-and low-speed maglev train

The invention relates to a low-noise current collecting system for a medium-and low-speed maglev train. The system comprises a ground power supply unit and a lateral current collector. The ground power supply unit comprises a power supply contact line laid below a maglev guide rail and along the lateral side of a rail beam, a current collecting face of the lateral current collector is in an arch current collecting structure, and slide contact current collection between the arch current collecting structure and the power supply contact line is realized. Compared with the prior art, the system has advantages that the noise level and probability of occurrence of impulsive noise in a current collecting process of the maglev train can be lowered, loss of the current collector is reduced, reliability and comfort of the system are improved, and system maintenance cost is reduced.

Owner:上海启喆科技有限公司

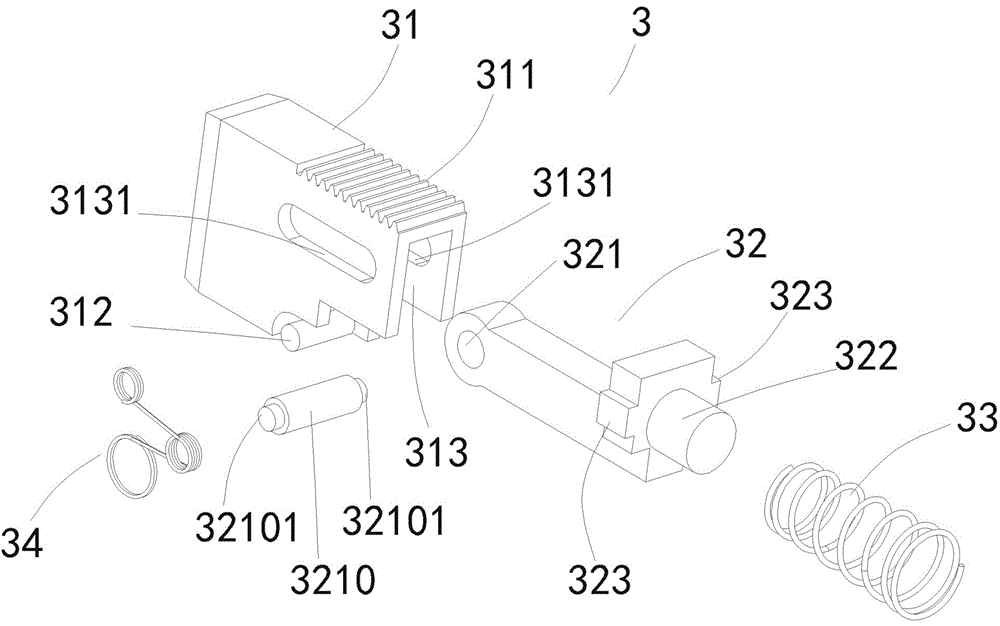

Storage bed unlocking device

The invention discloses a storage bed unlocking device. The storage bed unlocking device comprises a stop pin assembly which is arranged in a bed box, and a lock assembly which is arranged on a framework, wherein the lock assembly comprises a base, an adjusting ratchet wheel and a locking ratchet; the adjusting ratchet wheel is connected with a torsion spring, and is fixed on the base through a revolving shaft; the adjusting ratchet wheel is provided with an opening; the base is provided with a stop pin inlet; when the lock assembly is in an unlocking state, the opening in the adjusting ratchet wheel is coincided with the stop pin inlet of the base; when the lock assembly is in a locking state, the opening in the adjusting ratchet wheel is staggered away from the stop pin inlet of the base; the locking ratchet is connected with the base through a revolving shaft; the locking ratchet is provided with a short arm and a long arm; the short arm is matched with the adjusting ratchet wheel;the long arm is connected with a starting-resetting mechanism. The storage bed unlocking device does not produce noise during operation, has a multi-gear locking function, can still be locked under the situation of upward-downward deviation of the stop pin due to mounting error, and is easy and safe to operate.

Owner:SUSPA (NANJING) CO LTD

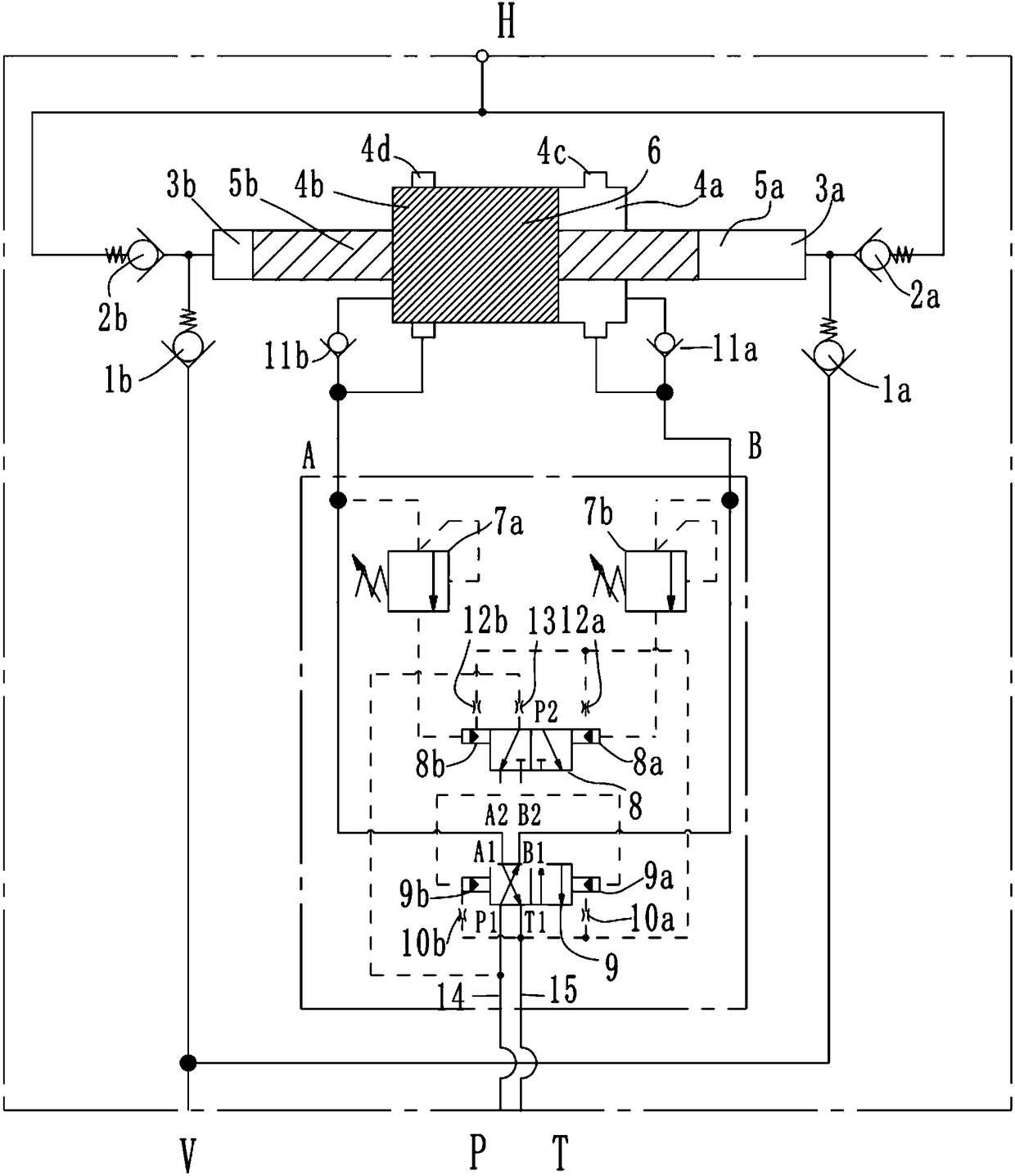

Hydraulic mud pump

The invention discloses a hydraulic mud pump which is provided with an oil inlet P, an oil return opening T, a pulp inlet V and a high-pressure pulp outlet H, and comprises a pressure cylinder and a hydraulic operated directional valve assembly. The pressure cylinder comprises a low pressure cylinder, a low pressure piston, a left high pressure plunger, a right high pressure plunger, a left high pressure cylinder and a right high pressure cylinder; a first oil inlet passageway, a second oil inlet passageway, a first control passageway and a second control passageway are arranged on the low pressure cylinder; an annular communicating groove is formed in the low pressure piston; when the low pressure piston leftwards moves to a position completely covering a first through-flow groove, the first oil inlet passageway and the first control passageway communicate through the communicating groove, the hydraulic operated directional valve assembly is controlled to reverse, and the low-pressurepiston is braked through a sealed left piston cavity; and when the low pressure piston rightwards moves to a position completely covering a second through-flow groove, the second oil inlet passagewayand the second control passageway communicate through the communicating groove, the hydraulic operated directional valve assembly is controlled to reverse, and the low-pressure piston is braked through a sealed right piston cavity. The hydraulic mud pump not only is simple in structure, but also has no need to be electrically controlled, and has low noise.

Owner:高建国

High-efficiency positive displacement pump

ActiveCN104763619AImprove work efficiencyAvoid collisionPositive displacement pump componentsFlexible member pumpsWork periodWork cycle

The invention provides a high-efficiency positive displacement pump. The high-efficiency positive displacement pump comprises a case, a motor, a worm, a worm gear, an eccentric shaft, a shaft and a pump head; the motor is connected with the worm rod by use of a worm sleeve; the lower end of the worm is positioned and connected with the case by use of a bearing; the worm drives the worm gear to rotate; the worm drives the eccentric shaft to rotate; the eccentric shaft drives the shaft to reciprocate in the pump head; the pump head comprises a left pump head and a right pump head, the two of which are arranged oppositely and connected by use of a sliding sleeve. Compared with the prior art, the high-efficiency positive displacement pump has the beneficial effects that the dual-pump head structure is adopted so that a liquid can be suctioned and discharged twice in one working period of the connecting rod, and the working efficiency is doubled in contrast with the prior art, the impact problem of engagement is overcome, the impact of toothed surfaces is avoided and no impact noise is generated, and therefore, the service life of the pump can be prolonged to a large extent.

Owner:邱列扬 +1

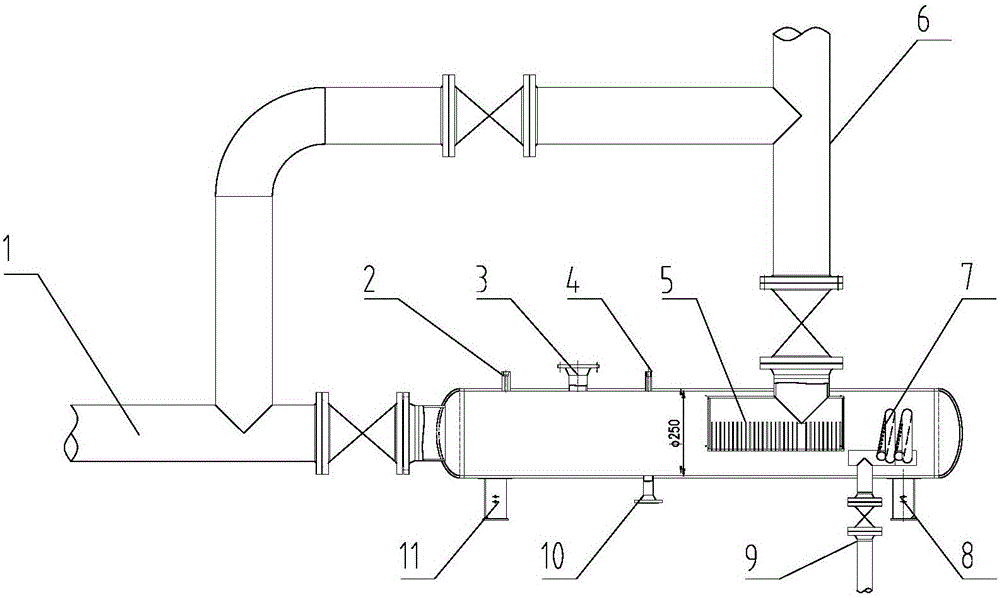

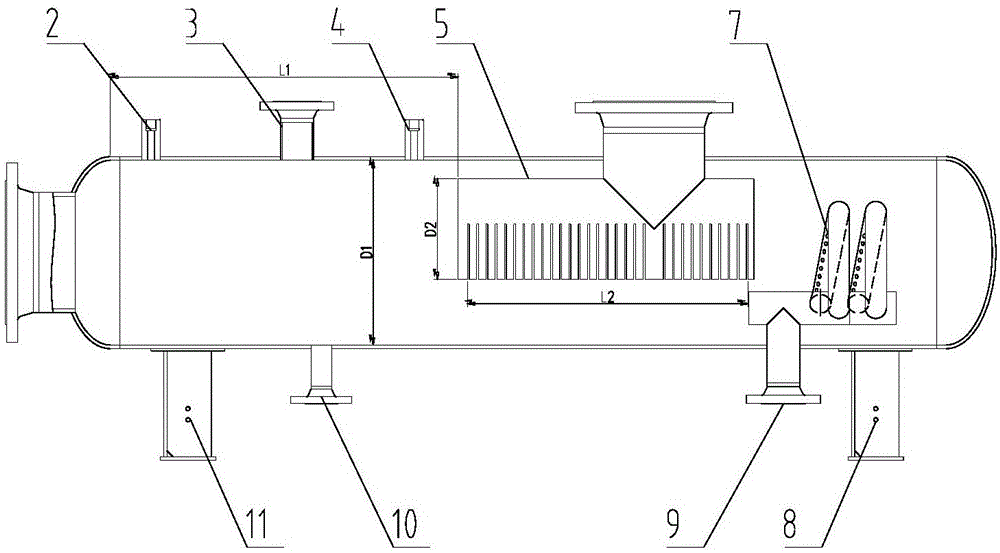

Steam mixer

ActiveCN106268404ARelieve stress shockReduce pressure shockFlow mixersTransportation and packagingEngineeringWater hammer

The invention discloses a steam mixer. The top of one end of a heater shell is connected with a main steam pipe through a flow regulating valve, the other end of the heater shell is connected with a steam mixing pipe through a sluice valve or a stopping valve, the main steam pipe is connected with the steam mixing pipe through a sluice valve or a stopping valve, the bottom of the heater shell is connected with a steam heating pipe through a flow regulating valve, the main steam pipe extends into the heater shell and is provided with main steam distributing pipes, the main steam distributing pipes are evenly distributed in the axial direction of the heater shell, airflow is parallel to the radial direction of the heater shell, and the steam heating pipe extends into the heater shell and is provided with a combined spraying pipe. Large-flow saturated steam and superheated steam with the roughly-matched pressure are mixed in the device, and micro-superheating steam with the certain micro superheat degree is formed; water hammer impacting generated when steam is delivered through a pipe network can be effectively reduced, and the steam mixer is simple, convenient to use and maintain and low in running noise, and is an energy-saving device for mixing steam.

Owner:青岛康泰重工机械有限公司

Earpiece without impulse and high frequency noise

InactiveCN1376374AImprove qualityEliminate high frequency noiseSupra/circum aural earpiecesDeaf-aid setsInterior spaceThroat

A "cover-mounted receiver structure with no impact noise and no high-frequency noise", comprising a receiver body and a horn placed in the inner space of the receiver body, wherein one side of the receiver body is pierced At least one sound hole is provided, a ring of sounding board is set on the peripheral surface of the horn, and an appropriate position on one side of the sounding board is fixed on the inner wall of the receiver body, and the two sides of the loudspeaker are The relatively low intensity value of the sound pressure on the side of the voice power output end is output towards the sound outlet of the receiver body; when people wear it to listen to music (Music) or receive voice (Voice), in addition to effectively preventing high-intensity The sound pressure impacts the ear, and at the same time, the superposition and interference of two sound waves with different high and low intensity sound pressures can be used, so that people can obtain a high-quality clear sound field without noise.

Owner:林仲宇

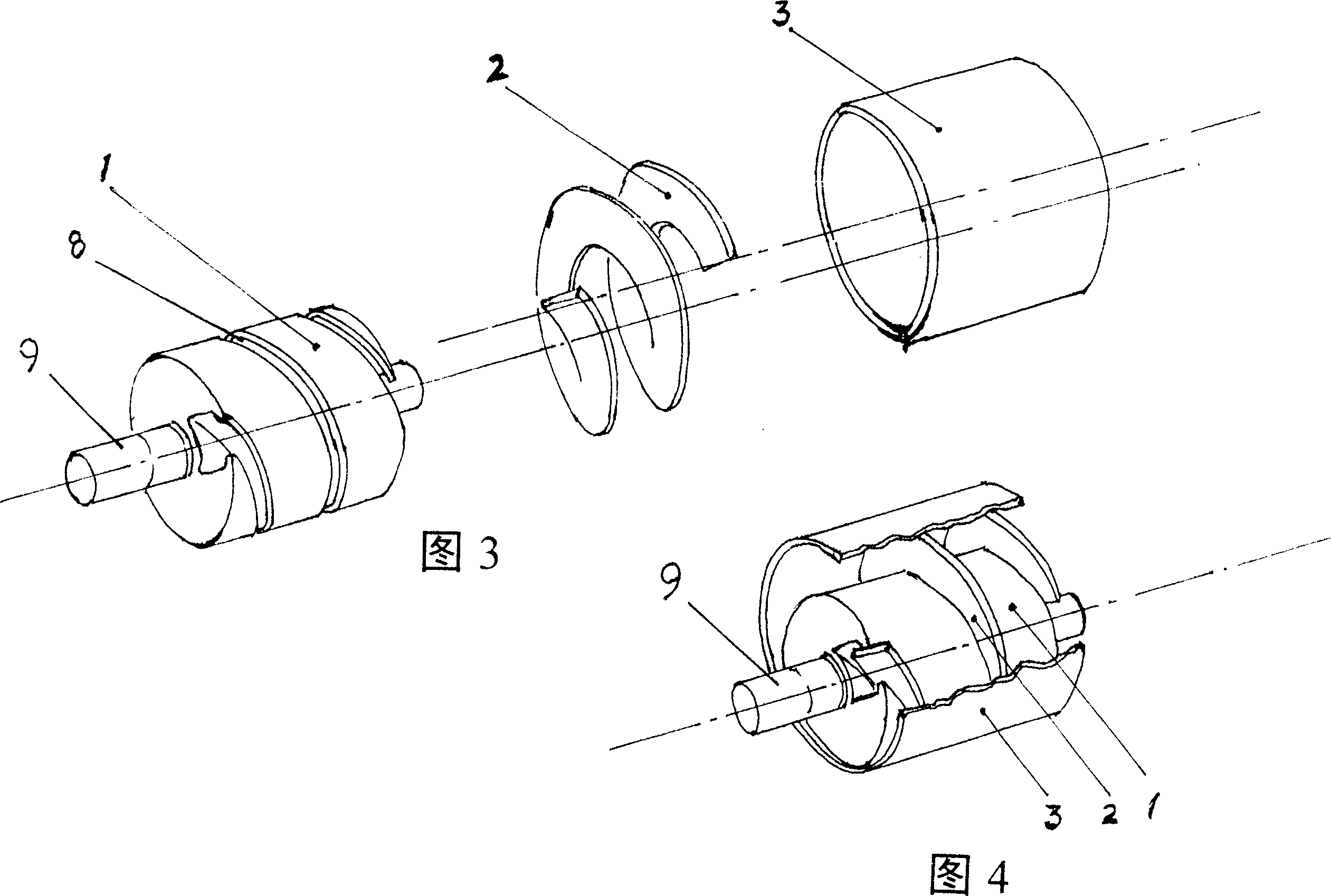

Rotation impeller blade pump

InactiveCN1447028AGuaranteed accuracyExtended service lifeRotary piston pumpsRotary piston liquid enginesImpellerEngineering

This invention relates to a rotary vane pump includes a rotor, a shell, medium inlet, medium pump outlet, in which, a screw slot is on the rotor, a screw rotary vane is inserted on the slot with follower slecve between the shell and the vane, the spindle nose of the rotor and the screw vane central line are of off-center structure. This invention has advantages of mechanicam pumps.

Owner:彭德高

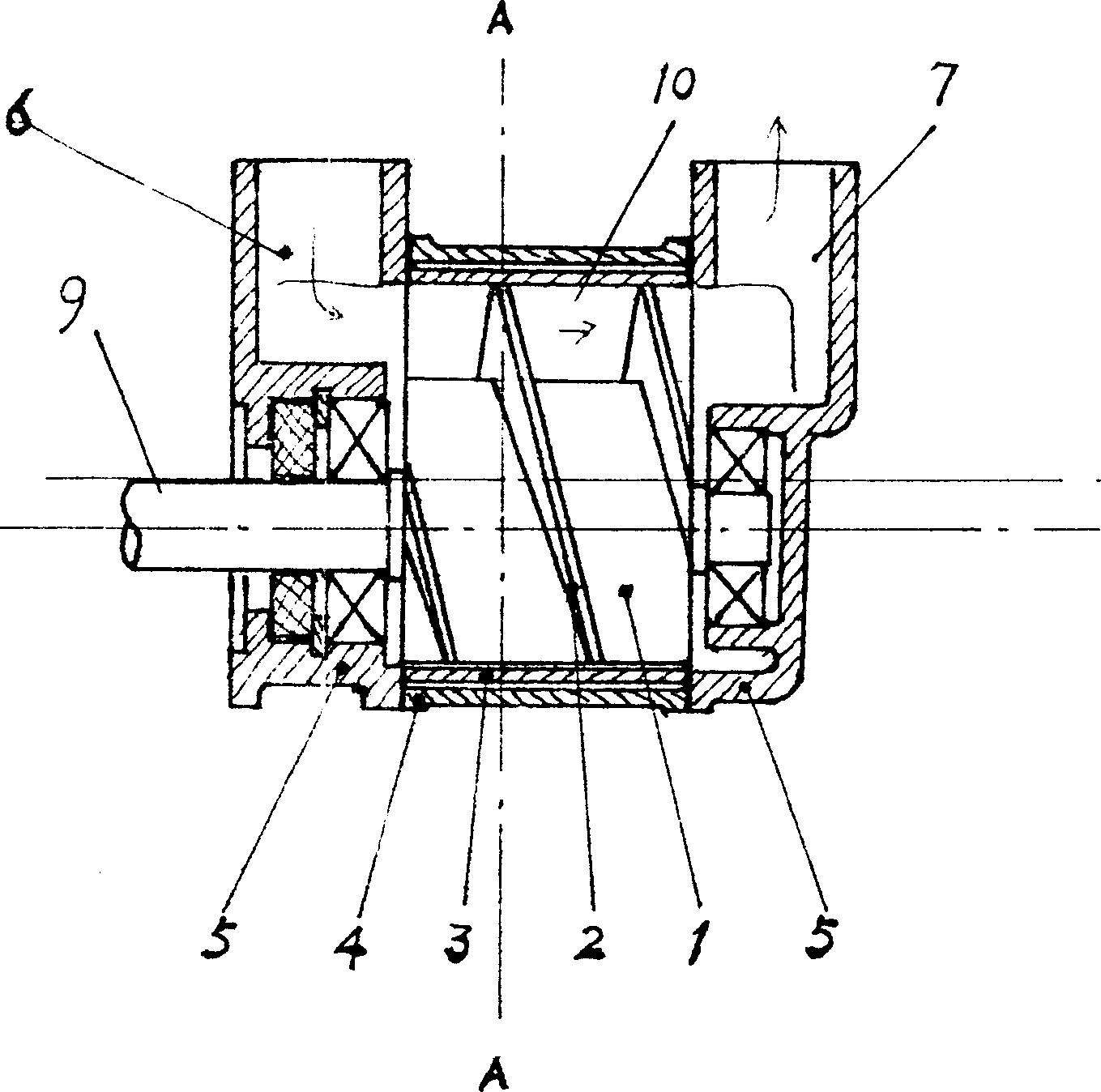

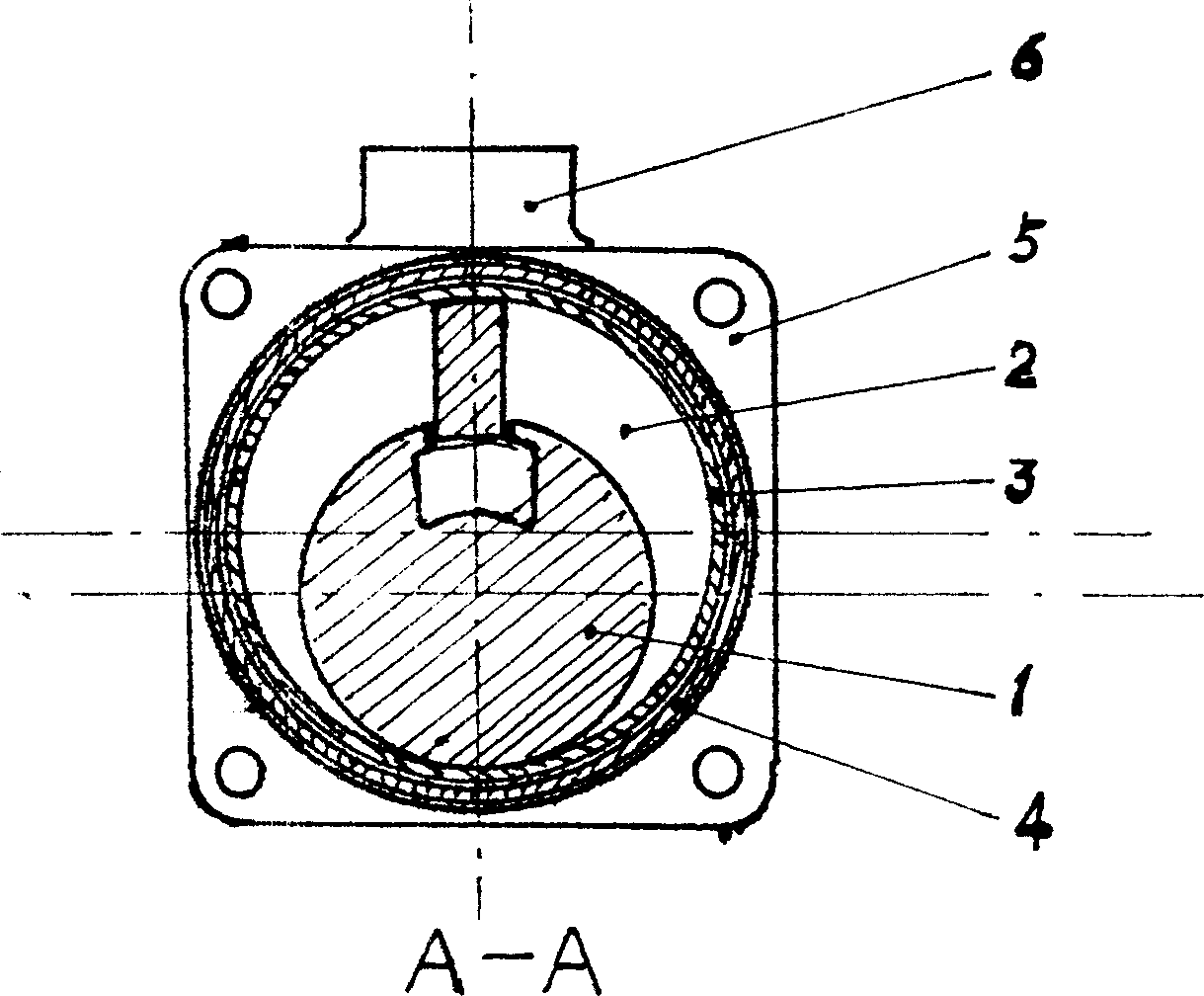

Rotation type air compressor

InactiveCN104131976ANo impact noiseWon't get angrySealing arrangement for pumpsRotary piston pumpsAxial compressorReciprocating motion

The invention discloses a rotation type air compressor which comprises a rotor, a shell, an air inlet and an air outlet, wherein a shell chamber which can compress air is formed between the rotor and the shell; the rotor is arranged inside the shell chamber in an eccentric manner; an airtight contact part is arranged between one side of the rotor and the lower side of the shell chamber; the air inlet and the air outlet are respectively formed in two sides of the airtight contact part; end part sealing devices are arranged at two ends of the shell chamber; a rotor groove is formed in the rotor; a tongue piece device which makes reciprocation movement inside the rotor groove is arranged in the rotor groove; the end part of a tongue piece of the tongue piece device is always in airtight contact with the inner wall of the shell chamber of the shell and can compress the air inside the shell chamber when the rotor rotates. When the air compressor operates, as the rotor is arranged in the eccentric manner, one side of the rotor is in airtight contact with the shell chamber, and the tongue piece device makes reciprocation movement inside the rotor groove when the rotor rotates, the air sealed in the shell chamber is compressed, high pressure air is discharged from the air outlet, meanwhile, the air is sucked in through the air inlet, and the purpose of acquiring compressed air is achieved in the circulation and reciprocation movement.

Owner:王喜来

Hydraulically-driven mud pump

The invention discloses a hydraulically-driven mud pump. The hydraulically-driven mud pump is provided with an oil inlet port P, an oil return port T, a mud inlet port V and a high-pressure mud outletport H. The hydraulically-driven mud pump comprises a pressurization cylinder and a hydraulically-controlled reversing valve assembly, wherein the pressurization cylinder comprises a low-pressure cylinder, a low-pressure piston, a left high-pressure plunger, a right high-pressure plunger, a left high-pressure cylinder and a right high-pressure cylinder, and a first through-flow groove and a second through-flow groove are formed in the low-pressure cylinder; when the low-pressure piston moves to the left and reaches to a position that the low-pressure piston completely shields the first through-flow groove, the low-pressure piston brakes through an airtight left piston cavity, and triggers the hydraulically-controlled reversing valve assembly to act to reverse; and when the low-pressure piston moves to the right and reaches to a position that the low-pressure piston completely shields the second through-flow groove, the low-pressure piston brakes through an airtight right piston cavity, and triggers the hydraulically-controlled reversing valve assembly to act to reverse. The hydraulically-driven mud pump is simple in structure, does not need to be controlled through electronic control, and is low in noise.

Owner:阿奥艾斯海洋工程(上海)有限公司

Tank-use adaptive shell-pressing device

The invention relates to a tank-use adaptive shell-pressing device comprising a gas cylinder and a hammer. The device is characterized in that a composite valve block in which speed regulation and pressure regulation valve parts are integrated is arranged on the bottom of the gas cylinder; and a gas source enters the cavity of the gas cylinder through the speed regulation and pressure regulation valve parts in the composite valve block, and pushes a piston rod to move up and down. The tank-use adaptive shell-pressing device also comprises a lower-part guiding device used for ensuring the smooth operation of the shell-pressing hammer. The lower-part guiding device which is composed of a slide sleeve and a guiding cylinder is arranged below the gas cylinder. According to the device, traditional impact shell-beating is changed into slow shell-pressing, and shell-pressing is automatically changed into impact shell-beating after meet resistance. Therefore, air consumption is greatly reduced, and energy consumption is saved. The device has the characteristics of smooth operation, long service life, damage resistance, low maintenance volume, and reduced labor intensity.

Owner:SHENYANG BOYU TECH

A magnetic mute lock body

The invention relates to a hardware door lock fitting, and discloses a magnetic silent lock body. The magnetic silent lock body is provided with a box bottom assembly, a driving assembly, a deadbolt assembly, a buckling box assembly and a handle stirrer, wherein the driving assembly consists of a slide block, a gear and a three-circle torsion spring; the deadbolt assembly consists of a deadbolt, a deadbolt pull rod and a reset spring; the top of the deadbolt is provided with a rack B; the box bottom assembly is provided with a gear positioning column; the slide block is provided with a rack A and a magnet positioning hole; the deadbolt is provided with a rack B; a magnet B is arranged in the buckling box assembly; the magnet A is fixedly embedded into the magnet positioning hole in the slide block; the slide block is arranged in the box bottom assembly; the gear passes through the gear positioning column, and is meshed with the rack A and the rack B simultaneously. During door closing, the deadbolt extends outwards under the same-pole repellant force of the magnet A and the magnet B. The movement of the lock body is driven by the gear and the racks, and the overall movement process is stable and reliable without collision, so that the use handfeel of the lock body is improved, and a silencing effect is achieved.

Owner:GUANGDONG MINGMEN LOCKS IND

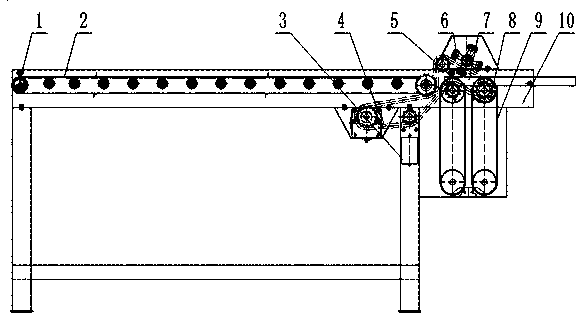

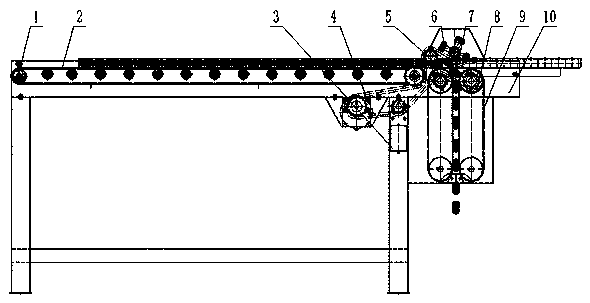

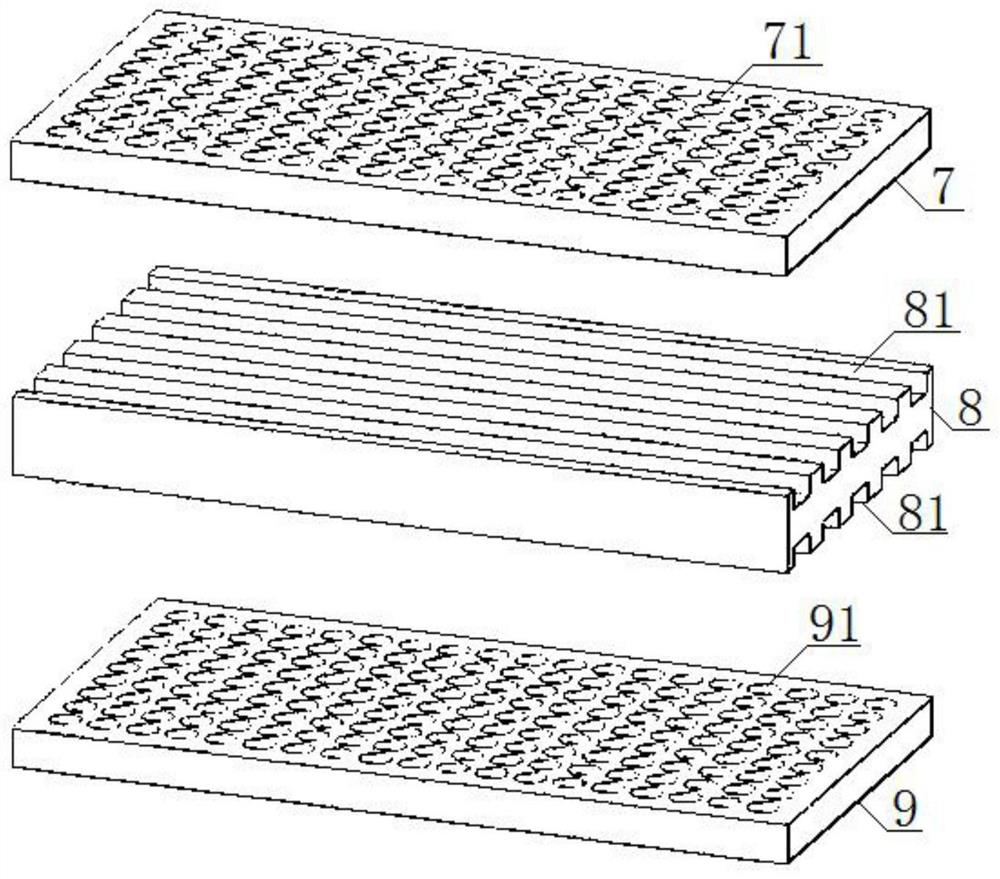

Square cocooning frame rolling cocoon harvester

InactiveCN109197788APlay a guiding roleIt has the function of tightening and guidingAnimal husbandryReciprocating motionSingle cluster

The invention discloses a square cocooning frame rolling cocoon harvester. Displacement sensors are fixed to the head and the tail ends of a transmission device respectively; the tail end displacementsensor is fixed in front of the inlet of the cocoon pressing roller, and the cocoon pressing roller is positioned behind and above the end of a conveyor belt; a controller and wiring harness are fixedly installed on the inner side of a rack, a power switch is arranged on the leg of the rack, and the wiring plug is led out from the leg of the side of the rack; a separating plate is arranged underthe cocoon pressing roller, and has thirteen holes for leaking cocoon strips, which are the same as the number of horizontal rows of cocooning frames; catch rollers are arranged in pairs, vertically arranged under holes in the separating plate in two left and right rows, each row of catch rollers is sleeved with a toothed wire drawing belt, and a blade which is closely attached to the surface is arranged on the inner side of the lower part of the wire drawing belt; sprockets are mounted on the main shaft ends of the two catch rollers. The invention provides a square cocooning frame rolling cocoon harvester on the picking line, which can complete the process of splitting the clusters at a constant speed, and reduces the time and space occupation of a single cluster. At the same time, thereis no reciprocating mechanism, no impact noise, stable machine operation and low power consumption.

Owner:SICHUAN HUINONG MACHINERY

X ray machine spot film system electric door device

InactiveCN100587592CNo impact noiseImpact noise is not generatedRadiation diagnosticsPhotographyX-rayEngineering

Owner:NEUSOFT MEDICAL SYST CO LTD

A hydraulically driven high-pressure grouting pump

ActiveCN108591001BAvoid collisionImprove efficiencyPiston pumpsPositive-displacement liquid enginesLow noiseControl engineering

The invention discloses a hydraulic-driven high-pressure grouting pump. The pump is provided with an oil inlet P, an oil return port T, a slurry inlet V and a high-pressure slurry outlet H, and comprises a pressurization cylinder and a hydraulic control reversing valve assembly; the pressurization cylinder comprises a low-pressure cylinder, a low-pressure piston, a left high-pressure plunger, a right high-pressure plunger, a left high-pressure cylinder and a right high-pressure cylinder, wherein the low-pressure cylinder is provided with a first oil inlet flow channel, a second oil inlet flowchannel, a first control flow channel and a second control flow channel, and an annular communication groove is formed in the low-pressure piston; when the low-pressure piston moves leftwards to the position where the low-pressure piston covers a first through-flow groove completely, the communication groove is used for communicating the first oil inlet flow channel with the first control flow channel to control reversing of the hydraulic control reversing valve assembly, and the low-pressure piston is braked through a closed left piston cavity; and when the low-pressure piston moves rightwards to the position where the low-pressure piston covers the second through-flow groove completely, the communication groove is used for communicating the second oil inlet flow channel with the second control flow channel to control reversing of the hydraulic control reversing valve assembly, and the low-pressure piston is braked through a closed right piston cavity. The high-pressure grouting pumpis simple in structure, electric control is not needed, and the low noise is achieved.

Owner:高军

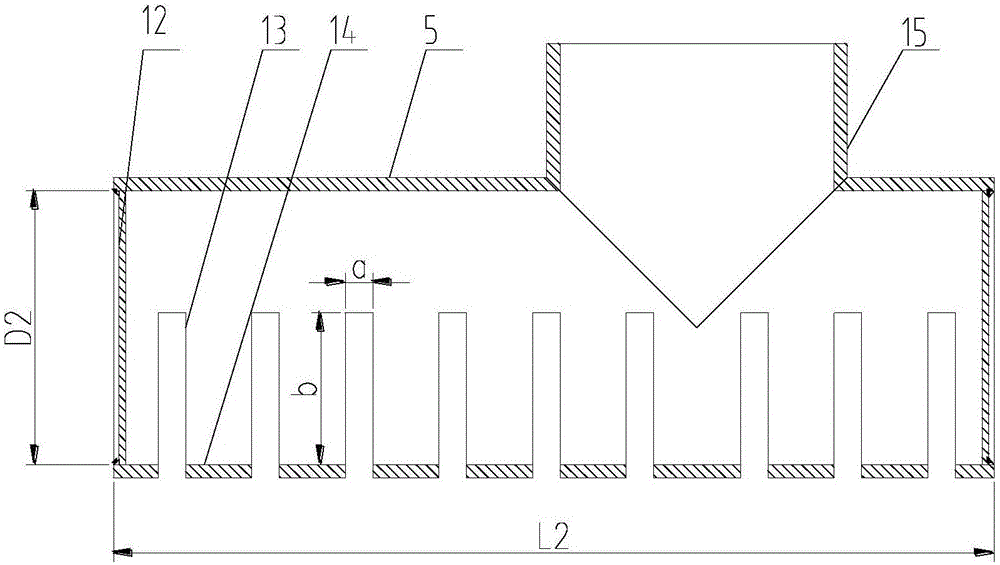

Air distributor and ship air conditioning system

ActiveCN112520005ASuppress turbulenceSuppress eddy currentAuxillariesVessel ventillation/heating/coolingEngineeringMechanics

The invention belongs to the technical field of ship air conditioning systems, and discloses an air distributor and a ship air conditioning system. The air distributor comprises an air inlet mechanism, a pressure stabilizing box, an air outlet mechanism and a flow guide folded plate. The air inlet mechanism and the air outlet mechanism are fixed on the pressure stabilizing box; the flow guide folded plate comprises a first flow guide plate and a second flow guide plate; the first flow guide plate is fixed to the inner wall of the pressure stabilizing box, and an air inlet buffer cavity is formed in the air inlet side in the pressure stabilizing box. The second flow guide plate is fixed to the inner wall of the pressure stabilizing box, and a pressure stabilizing buffer cavity is formed inthe air outlet side in the pressure stabilizing box. The second flow guide plate is connected with the first flow guide plate to form a V-like flow guide cap; an inner cavity of the V-like flow guidecap is communicated with the air outlet mechanism, and the V-like flow guide cap is located above an air outlet of the air outlet mechanism; a flow stabilizing channel is reserved between the air inlet buffer cavity and the pressure stabilizing buffer cavity. According to the air distributor and the ship air conditioning system, noise can be greatly reduced.

Owner:WUCHANG SHIPBUILDING IND

Left and right opening mechanism and refrigerator

ActiveCN106016927BOpen smoothlyClose smoothlyLighting and heating apparatusHingesGear driveGear wheel

Owner:HAIER SMART HOME CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com