Low-noise strong-impact weak-recoil electric hammer drill

A recoil, low-noise technology, used in engineering power tools and mining fields, can solve problems such as harming the health of operators, polluting the environment, and loud noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

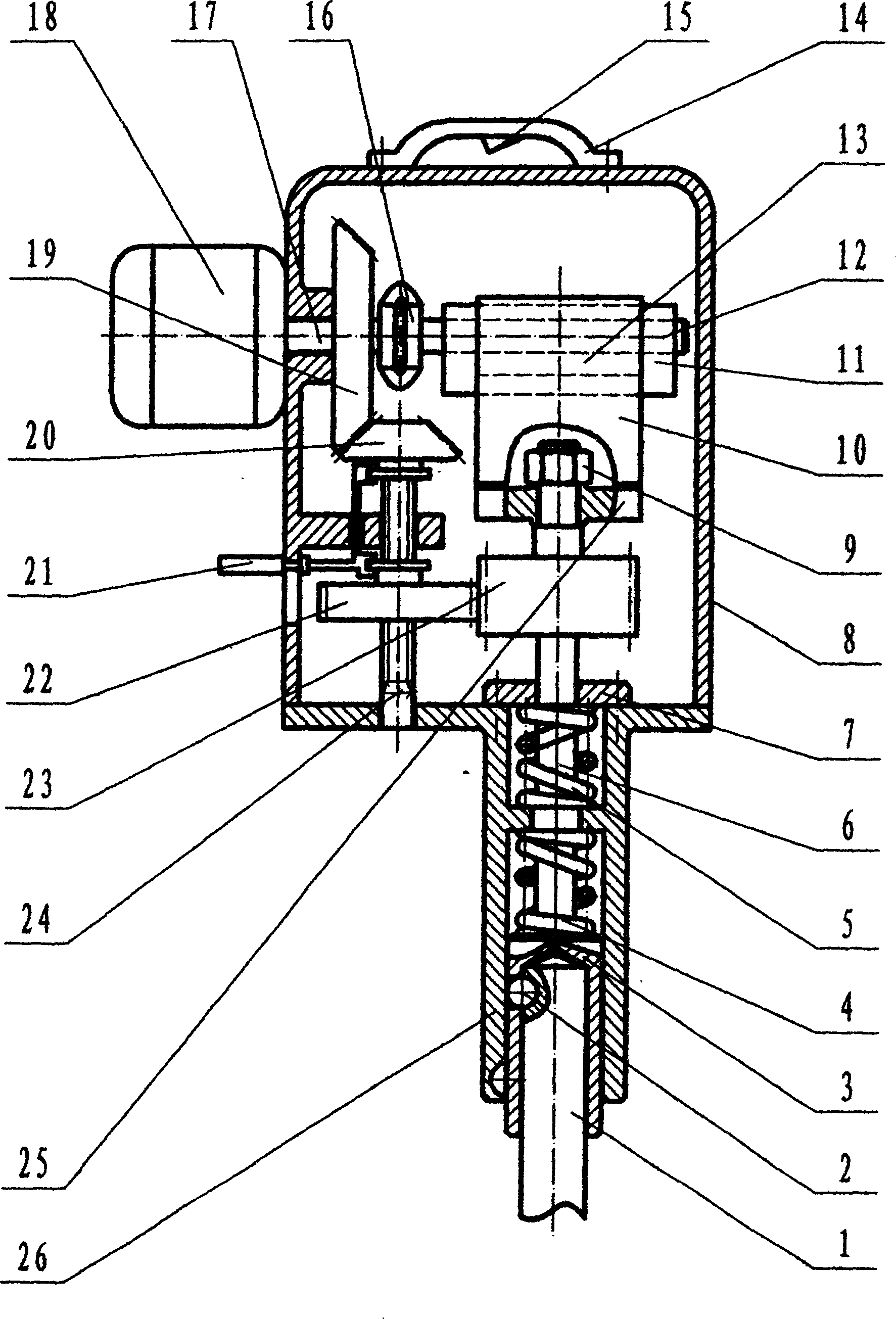

[0009] In the embodiment of the accompanying drawings, the drill pipe (1) is fixed on the slider (3) with a steel ball (2), the slider (3) and the power shaft (6) are made of an integral material, and the pressure plate (7) is sleeved on the On the power shaft (6), and fixed with the shaft sleeve (26), the slider (3) can slide up and down in the shaft sleeve (26), and the upper spring (5) and the lower spring ( 4) The position of the power shaft (6) in the shaft sleeve (26) can be maintained when the machine is stopped, and it can be used for vibration isolation when the machine is started. The shaft sleeve (26) is fixed on the casing (8), and the casing (8) There is a handle (14) on it, and an electric button (15) is arranged on the handle (14). The bevel gear A (19) is fixed on the motor shaft (17). (12) connection, the movable shaft (12) is installed on the movable bearing seat (13), the eccentric block (11) is fixed on the movable shaft (12), and the movable bearing seat (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com