X ray machine spot film system electric door device

An X-ray and electric door technology, which is applied in the field of X-ray machine point film system, can solve the problems of electrical control overload protection, failure to realize the filming function, and the door cannot be opened freely, so as to achieve no metal impact noise, increase practicality and aesthetics, Avoid the effect of overload protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

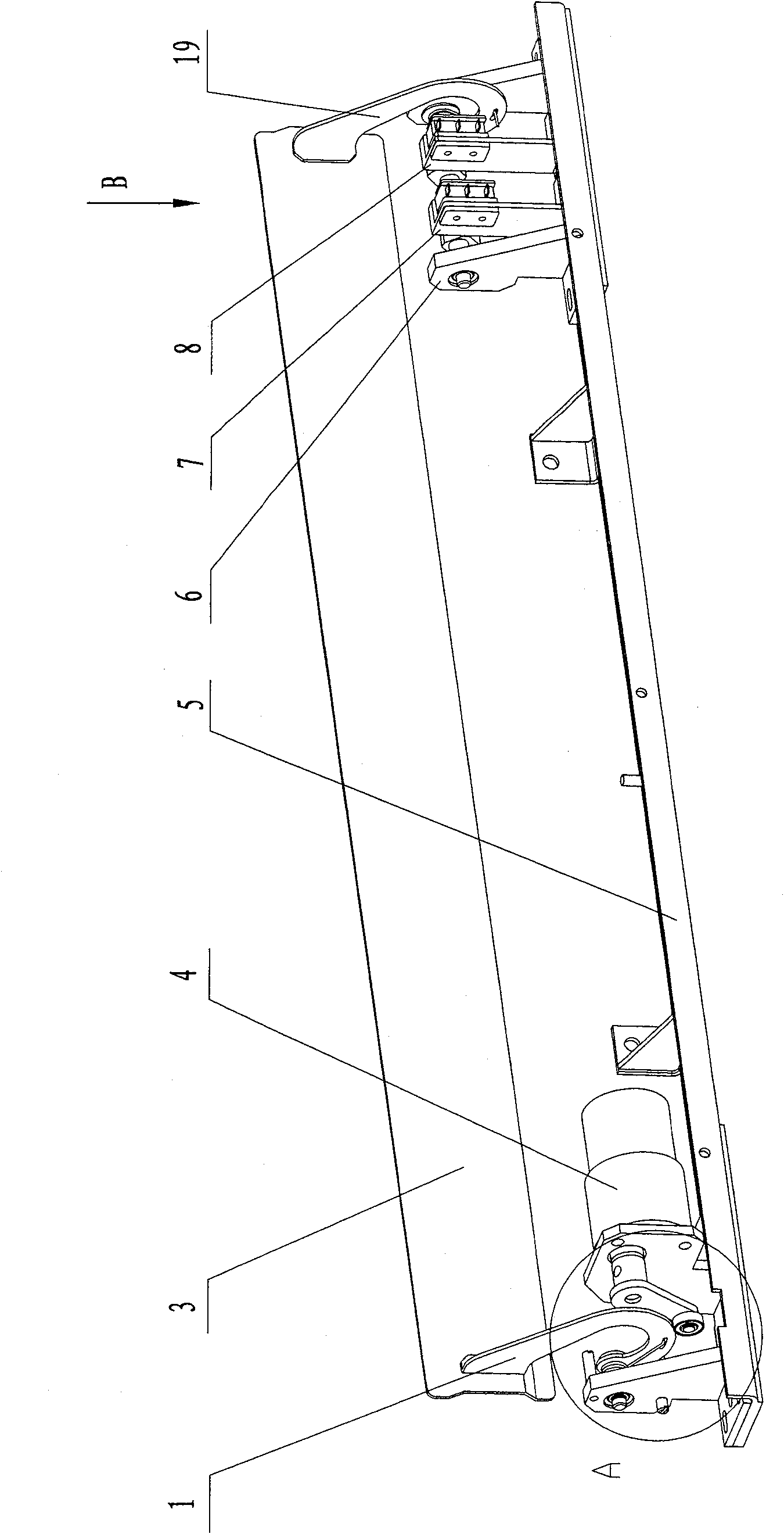

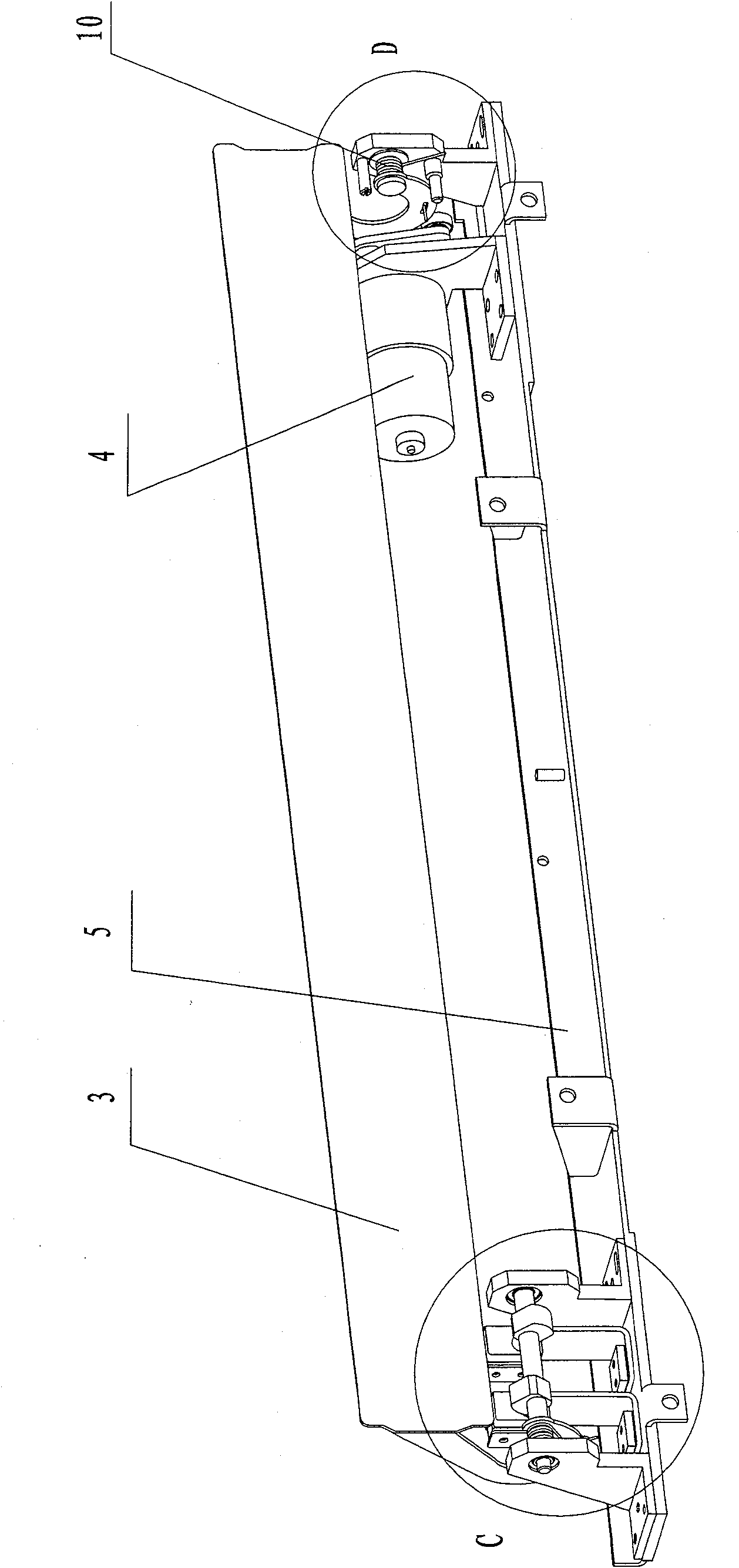

[0027] like Figure 2-7 As shown, the angle positioning device includes first and second travel switch assemblies 7, 8, camshaft 9 and cam 18, and one end of the camshaft 9 is arranged on the first support seat 6 fixedly connected to the support plate 5, and the other end is connected with the door The rotating shaft 12 is connected and rotates synchronously. The camshaft 9 is provided with two cams 18 with opposite flange directions. The first and second travel switch assemblies 7 and 8 are installed on the support plate 5 and are located on one side of the camshaft 9, respectively. Corresponding to the two cams 18.

Embodiment 2

[0029] like Figure 10 As shown, the angle positioning device includes the first and second stroke switch assemblies 7,8, camshaft 9 and cam 18, the first and second stroke switch assemblies 7,8 are arranged up and down, and the camshaft 9 is provided with a cam 18, which is located at two Between the travel switch components, one end of the camshaft 9 is arranged on the first support seat 6 fixedly connected to the support plate 5 , and the other end is synchronously connected with the door rotating shaft 12 .

[0030] Working principle of the present invention is:

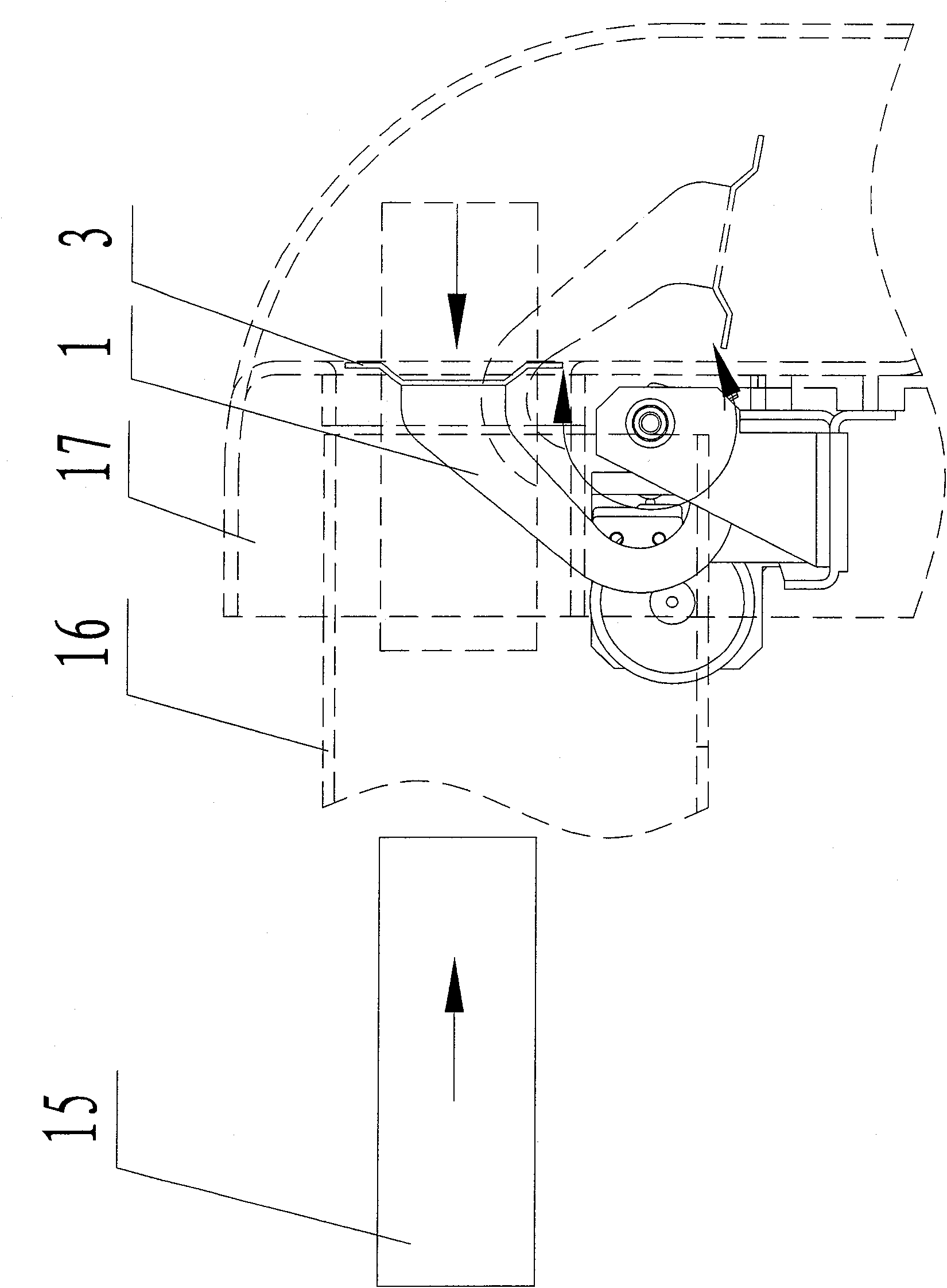

[0031] like figure 1 , Figure 8 and Figure 9 shown, where Figure 8 It is the state when the spot gate is closed (0°). When needing to put into the film box, press the switch on the operating panel of the point film system, the DC motor 4 works, and drives the fork 2 to rotate. During the rotation of the swing rod 2, the first rocker arm 1 at this end is promoted, and the dot film door 3 is gradually open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com