Square cocooning frame rolling cocoon harvester

A grid cluster and cocoon-picking technology, which is applied in animal husbandry and other fields, can solve problems such as bulky structure, low efficiency, and single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

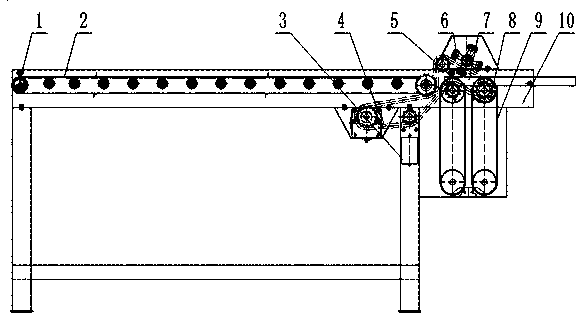

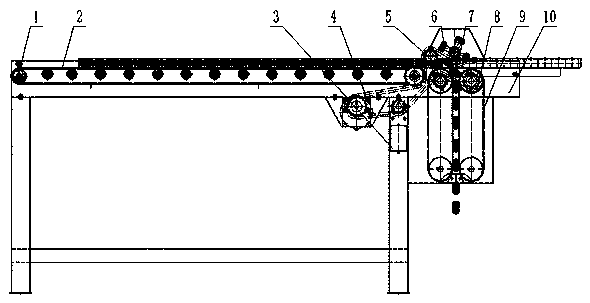

[0017] Such as figure 1 , 2 As shown, a grid cluster rolling cocoon picking machine includes: an infrared displacement sensor 1, a transmission device 2, a program controller 3, a transmission system 4, an infrared displacement sensor 5, a cocoon pressing roller 6, and a separation plate 7. Capture roller 8, ribbon 9, frame 10, infrared displacement sensor 1 and infrared displacement sensor 5 are respectively fixed on the head and tail ends of transmission device 2, and tail infrared displacement sensor 5 is fixed on Before the cocoon-pressing roller 6 cuts into the entrance; the cocoon-pressing roller 6 is placed on the back and above the tail end of the transmission device 2; The connecting plug is led out from the side; the separation plate 7 is placed under the cocoon pressing roller 6; there are thirteen cocoon leakage holes on the separation plate 7 which are the same as the number of cocoon clusters in the horizontal row; the catching rollers 8 are arranged in pairs, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com