Rotation impeller blade pump

A helical, medium pump technology, used in pumps, rotary piston pumps, rotary piston machines, etc., to achieve the effects of large pressure difference, low manufacturing and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

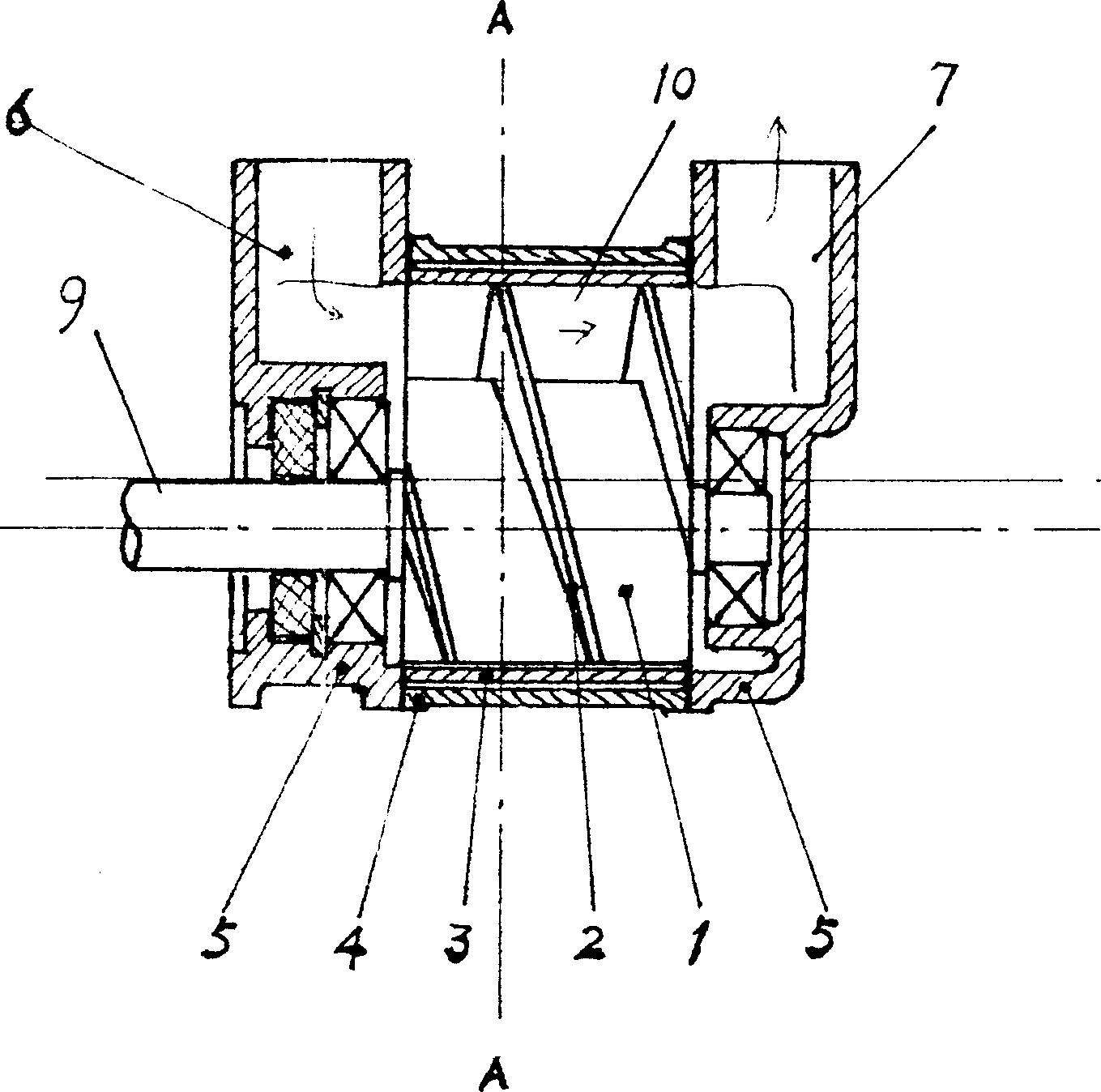

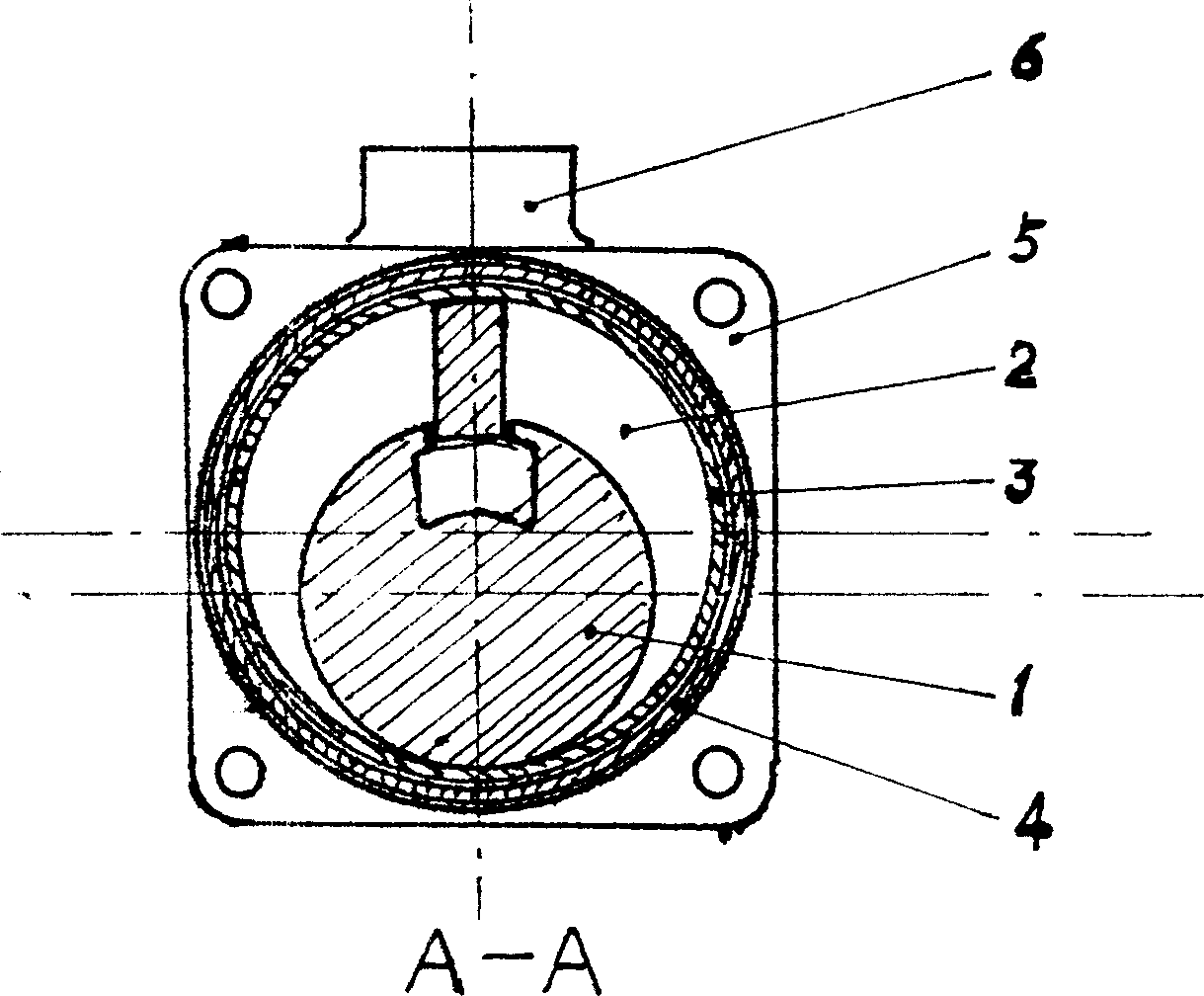

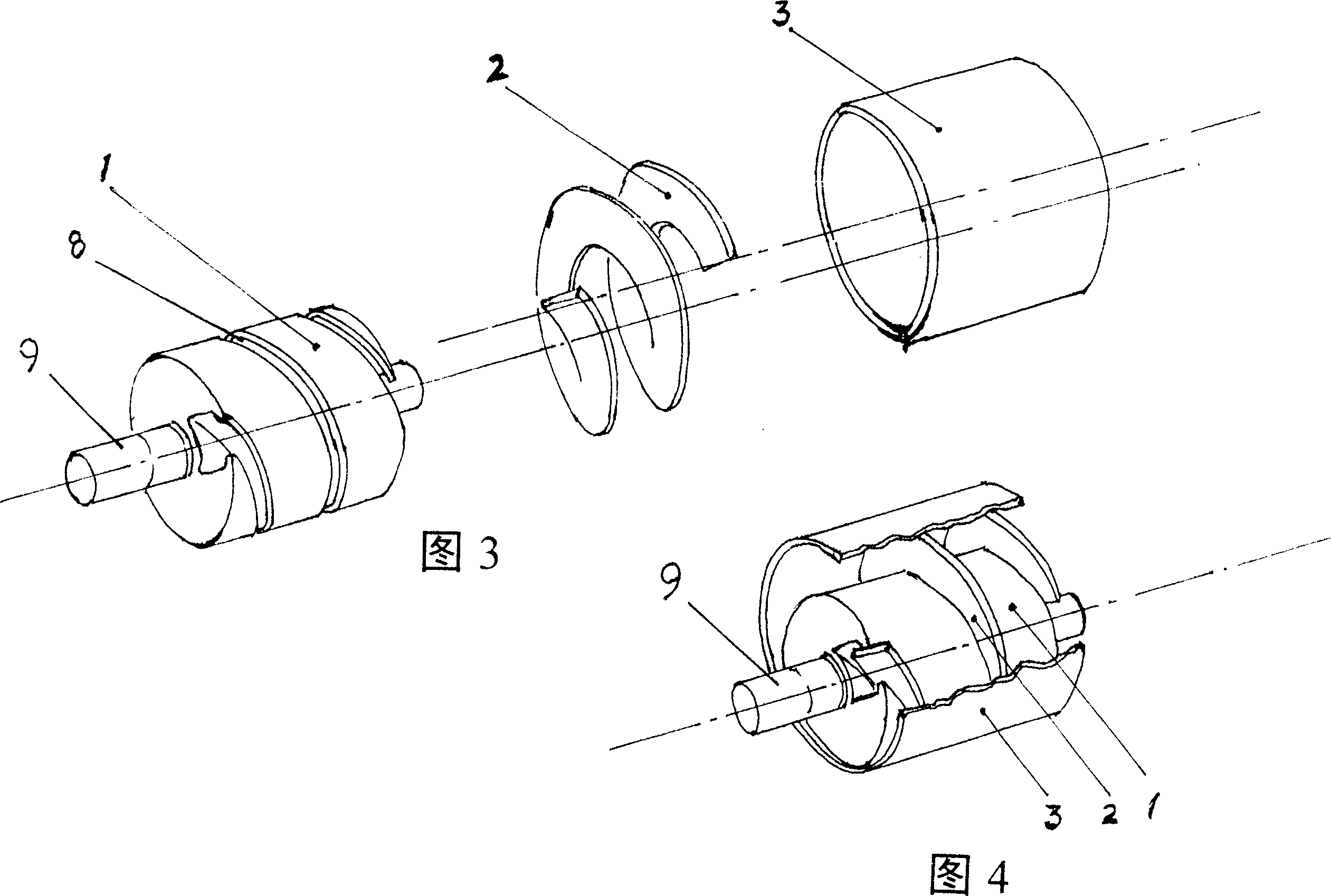

[0012] In the embodiment of the present invention, the rotor (1) is a cylindrical structure with helical grooves (8) processed on the axial surface for inserting the rotary blades (2), and there are shaft heads (9) at both ends as For positioning and power input. The rotary vane (2) is a helical structure like a compression spring with a flat cross-section and the same length as the rotor. The helical direction and pitch are consistent with the helical groove (8) of the rotor (1) and can be screwed into the rotor in the spiral groove (8). Its outer diameter and inner diameter are much larger than the outer diameter of the rotor (1) and the bottom diameter of the spiral groove (8). When the rotor (2) is combined with the rotor (1), it looks like a screw, but The rotary vane can slide eccentrically on the rotor (1), and when one side of the rotary vane is fully retracted into the helical groove (8) of the rotor, the other side slides out of the rotor like a crescent moon. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com