Adjustable damping valve arrangement

A damping valve and valve body technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as improving fatigue strength, no diaphragm axial support, etc., to achieve the effect of functional expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

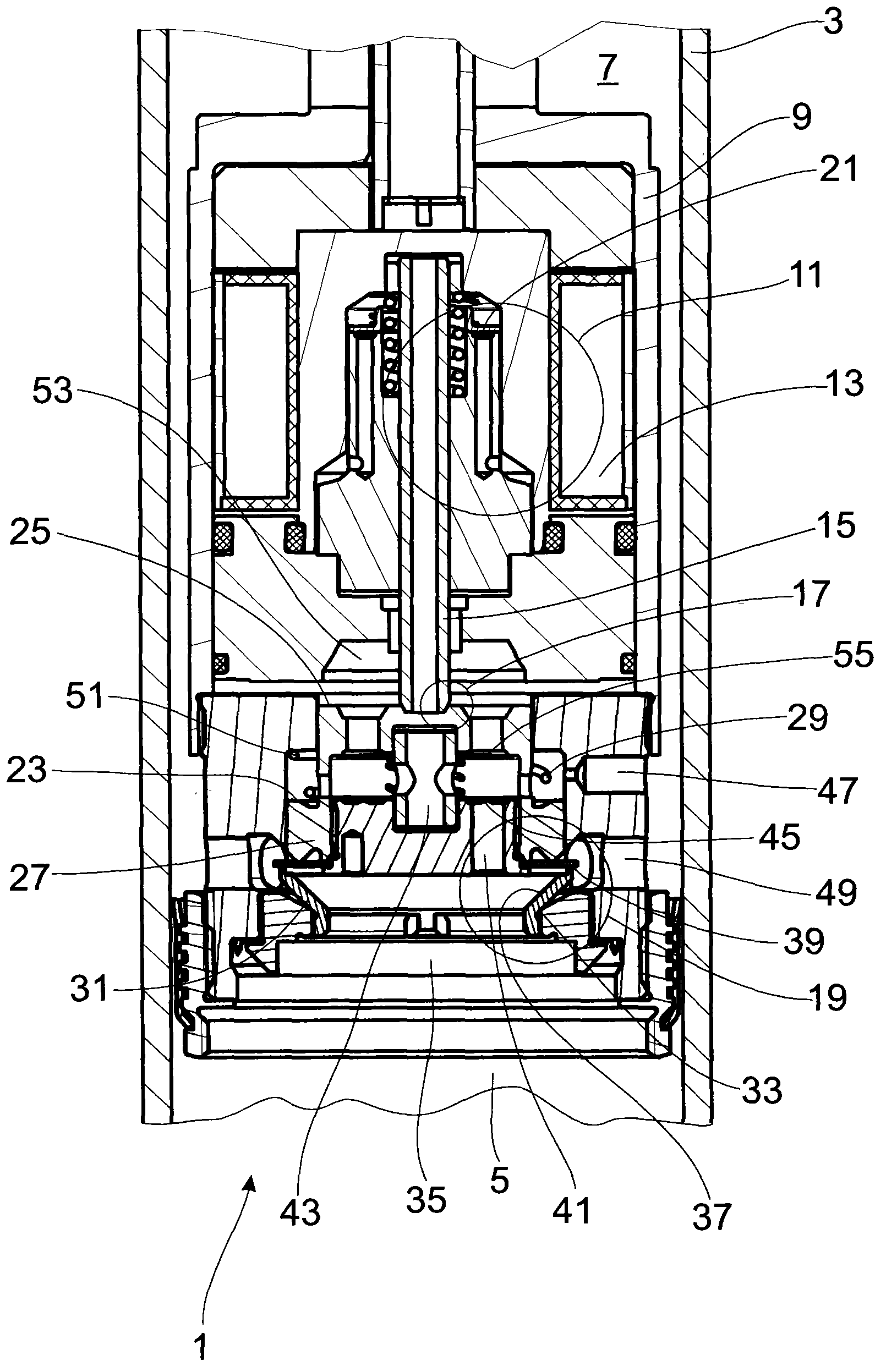

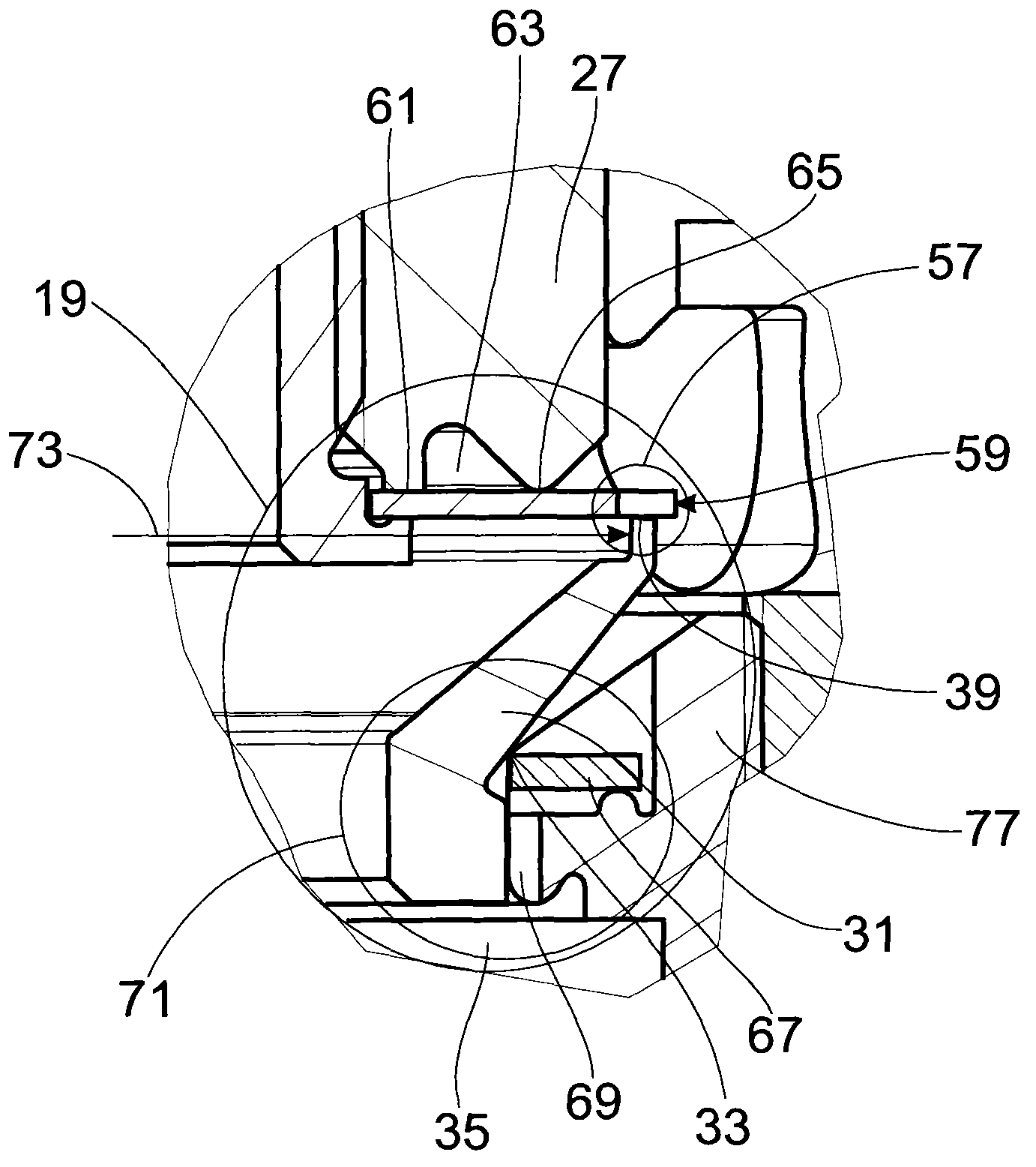

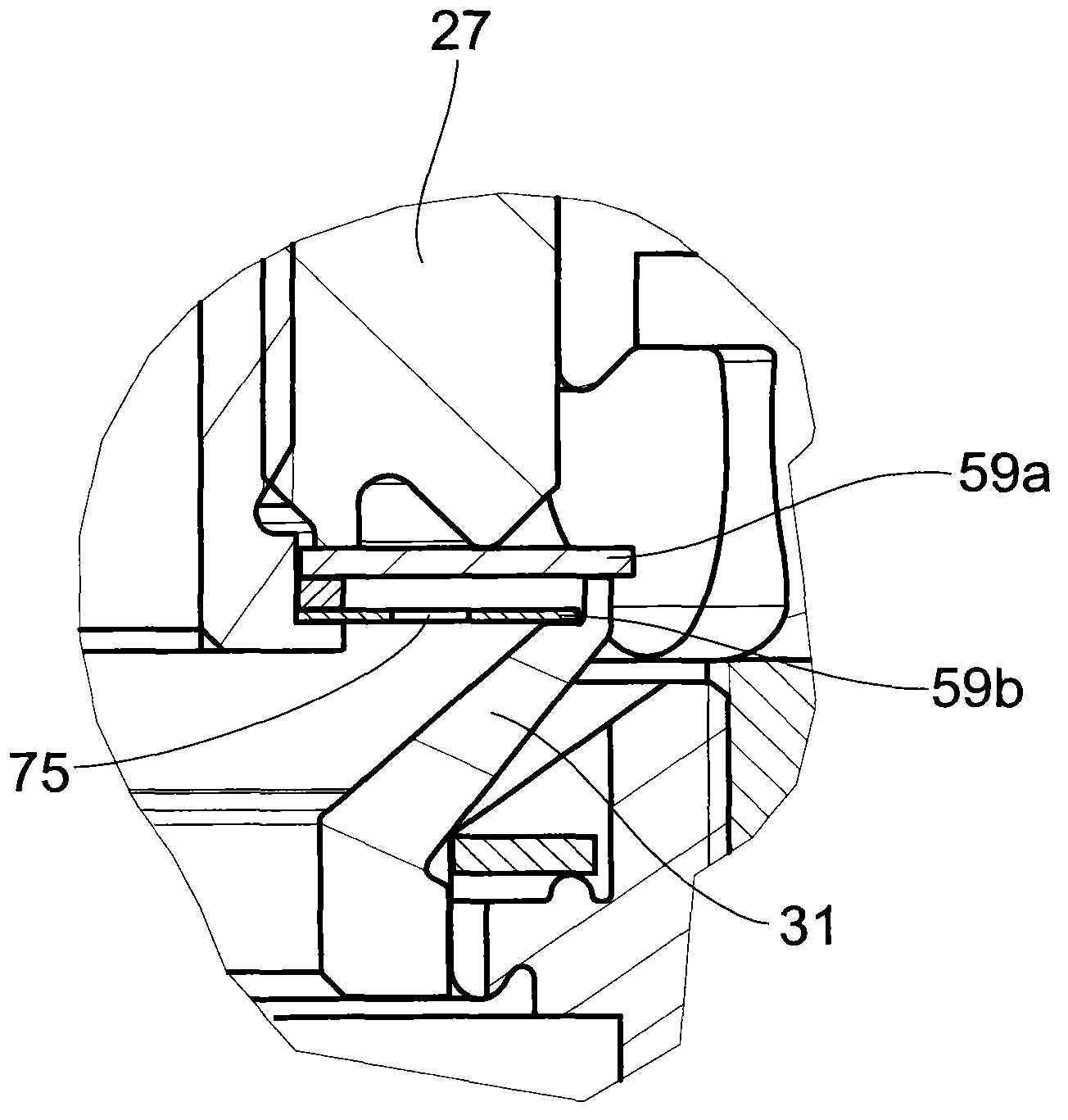

[0024] figure 1 A damping valve arrangement 1 for a shock absorber of any design is shown. The damping valve arrangement 1 can be arranged both within the cylinder 3 of the shock absorber between the two working chambers 5 ; 7 and also outside the cylinder 3 in a bypass line. Arranged in the damping valve housing 9 is an actuator 11 , which in this example comprises a solenoid coil 13 which exerts an axial actuating force on an axially movable pilot valve body 15 of a pilot valve 17 . The closing force on the main stage valve 19 can be influenced via the pilot valve 17 . This closing force is determined by the force of at least one valve spring 21 and the adjustment force of the actuator 11 acting against the valve spring force as well as the hydraulic closing force, which is controlled by the rigid main stage valve body 27 The pressure of the at least one pressure-loaded surface 23; 25 of .

[0025] The main-stage valve body 27 is additionally prestressed by a main-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com