Tank-use adaptive shell-pressing device

A self-adaptive, cylinder technology, which is applied in the field of electrolytic aluminum production equipment and self-adaptive shell pressing device, can solve the problems of affecting tank production, heavy maintenance work, and large gas consumption, so as to reduce the cost of spare parts and maintenance costs , save maintenance workload, and have significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] The technical solutions of the present invention will be described in detail below in conjunction with specific examples.

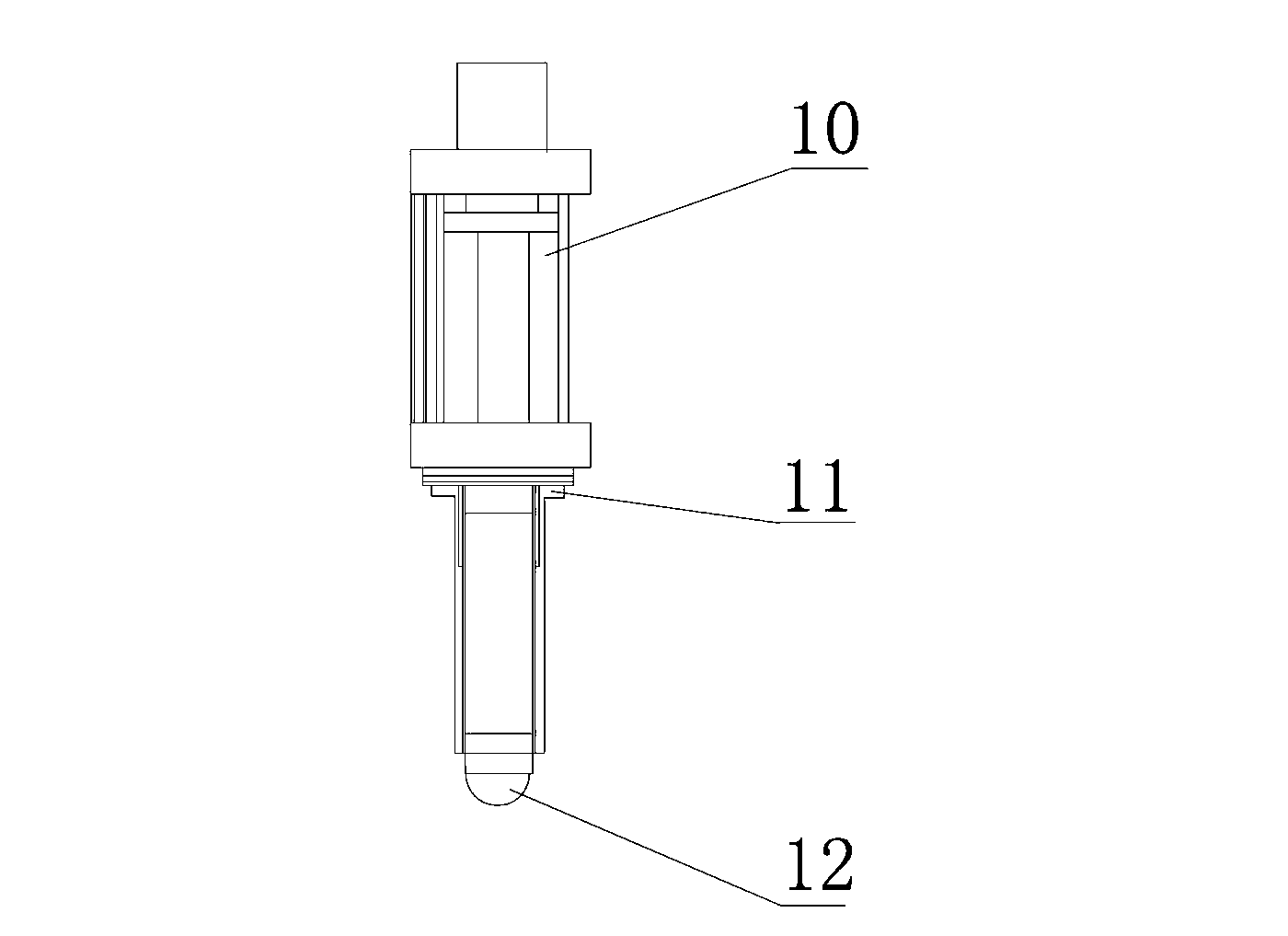

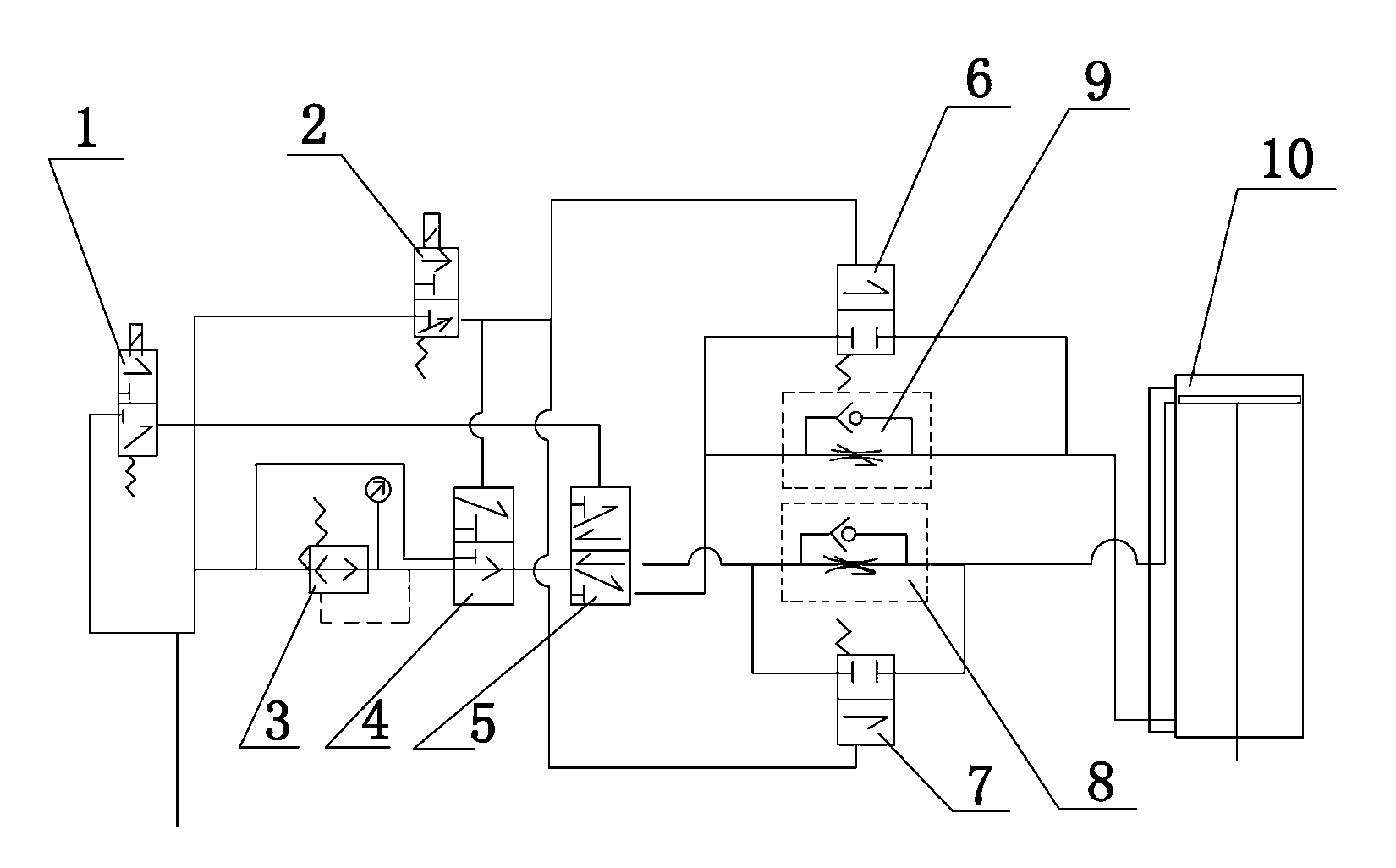

[0019] like figure 1 As shown, this self-adaptive shell pressing device for the tank includes a cylinder 10, a shell pressing hammer 12 and a lower guide device 11 that can ensure the stable operation of the hammer, wherein the bottom of the cylinder 10 is provided with a valve for speed regulation The combined valve block is combined into one, the air source enters the cylinder 10 cavity through the valve used for pressure regulation and speed regulation in the combined valve block, and pushes the piston to move up and down. The lower guide device 11 is composed of a sliding sleeve and a guide cylinder and is set on the Below the cylinder 10, a sensor and a time controller are also arranged in the pressure-adjustable and speed-regulating combination valve block.

[0020] figure 2 It is a schematic diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com