Caliper brake for elevator installations

A technology for caliper brakes and elevators, used in transportation and packaging, elevators, etc., which can solve problems such as fatigue fracture, vibration, and brake caliper trembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

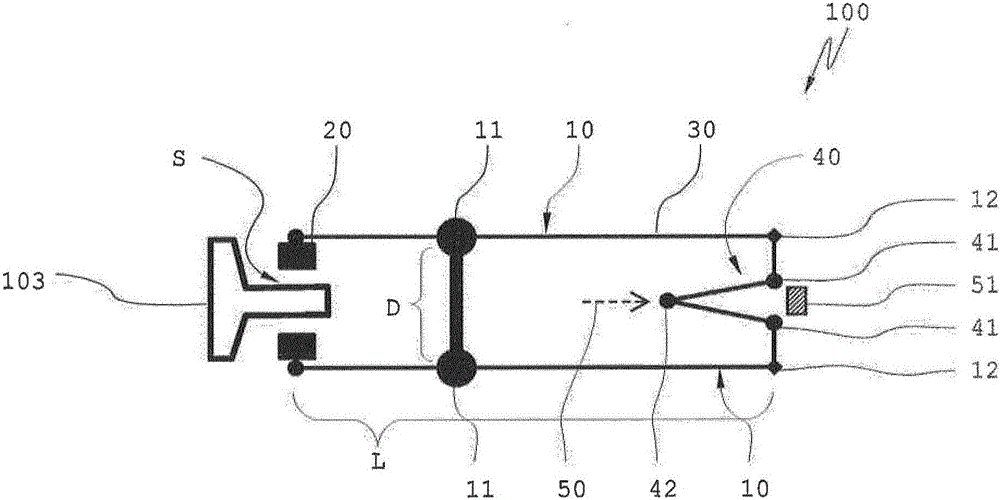

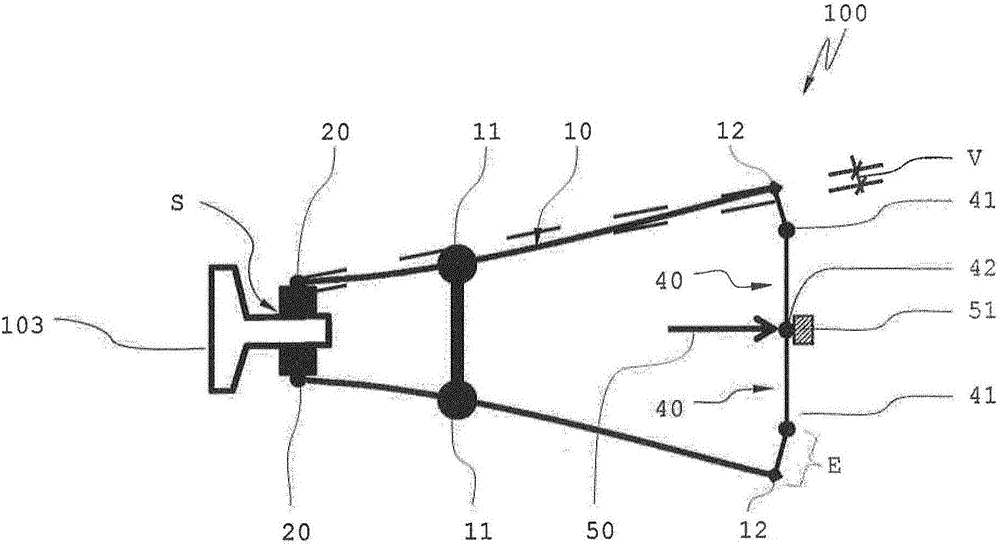

[0062] figure 1 A schematic view of a caliper brake 100 according to the invention is shown in a ready position. Caliper brake 100 has two brake calipers 10 which each have a pivot point 11 . The pivot point 11 is connected to the brake housing (not shown here). The two pivot points 11 of the brake caliper 10 have a distance D from one another. Here, the two brake calipers 10 are shown substantially parallel and in the standby position. The brake caliper 10 has a brake lining 20 at one end and a hinge point 12 at the other end. The brake arm 30 is located between the pivot point 11 and the hinge point 12 . The toggle hinge point 41 is located on the hinge point 12, and the toggle hinge point is connected with the toggle lever 40. The stop 51 is shown schematically. The brake caliper 10 has a length L. As shown in FIG. A guide rail 103 of the elevator is located between the two brake linings 20 of the brake caliper 10 . Between the guide rail 103 and the brake lining 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com