Hydraulic mud pump

A mud pump and hydraulic technology, applied in the field of hydraulic mud pumps, can solve the problems of unsuitable use, short service life, unreliability, etc., and achieve the effect of simple structure, long stroke and reduced stroke times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

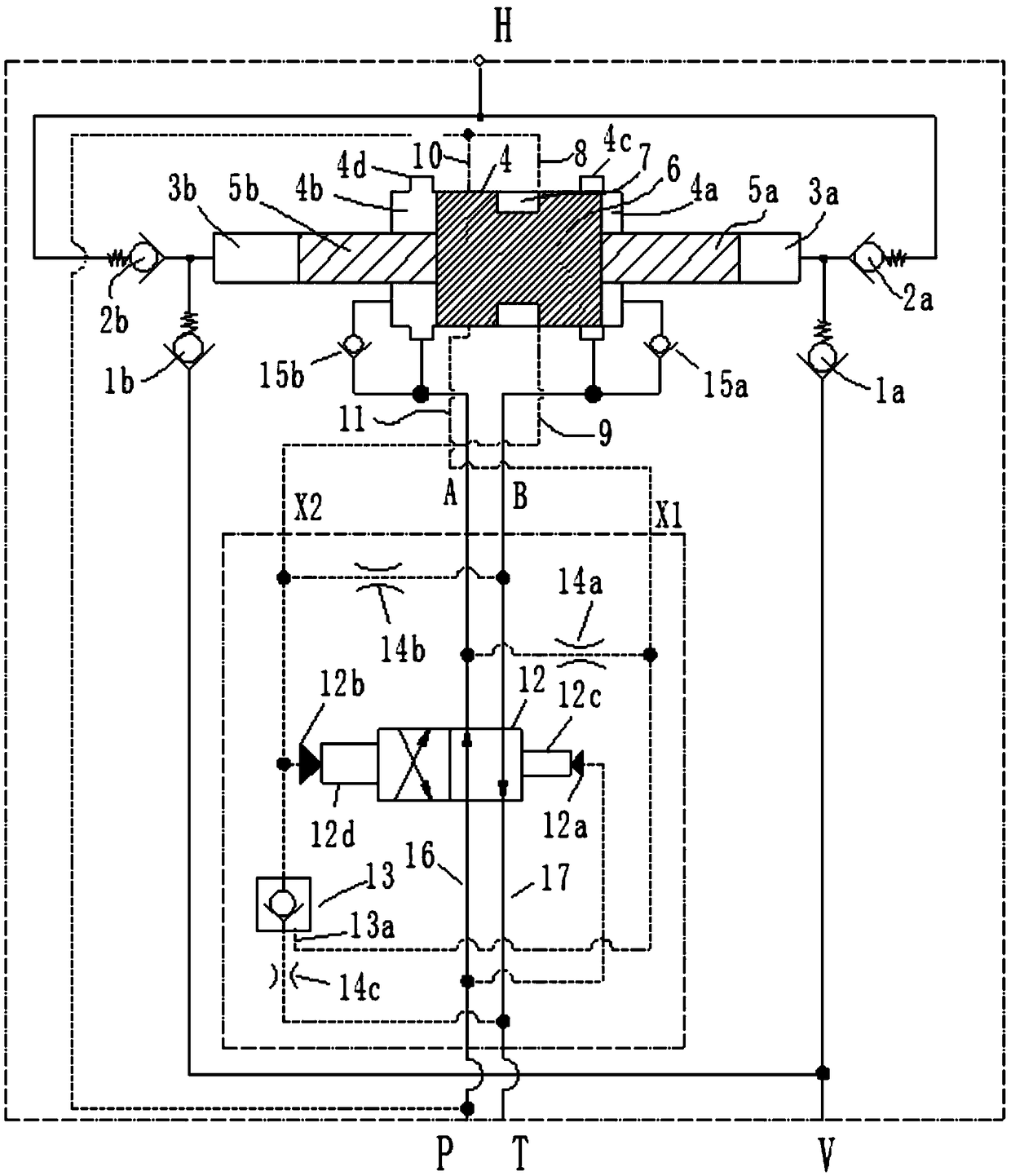

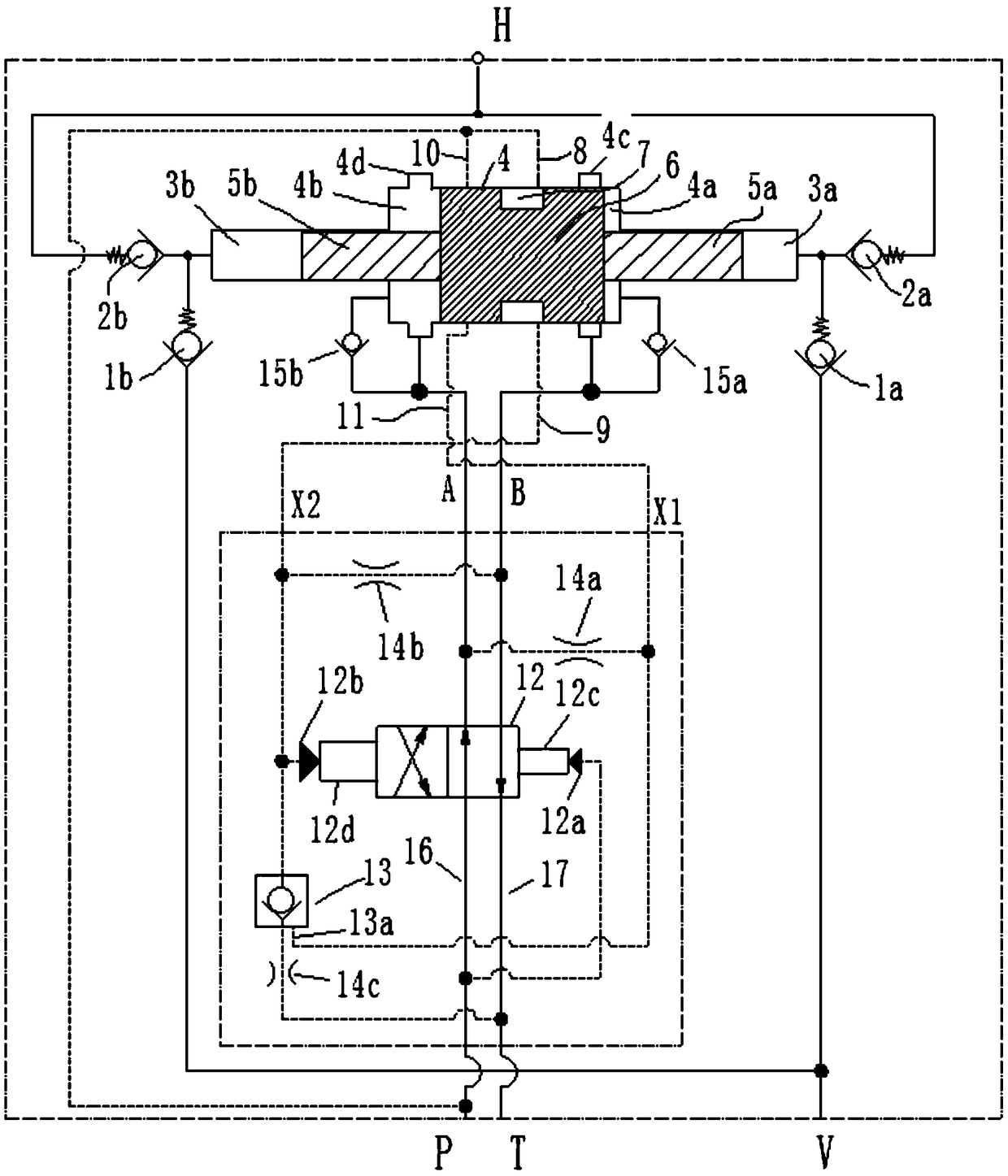

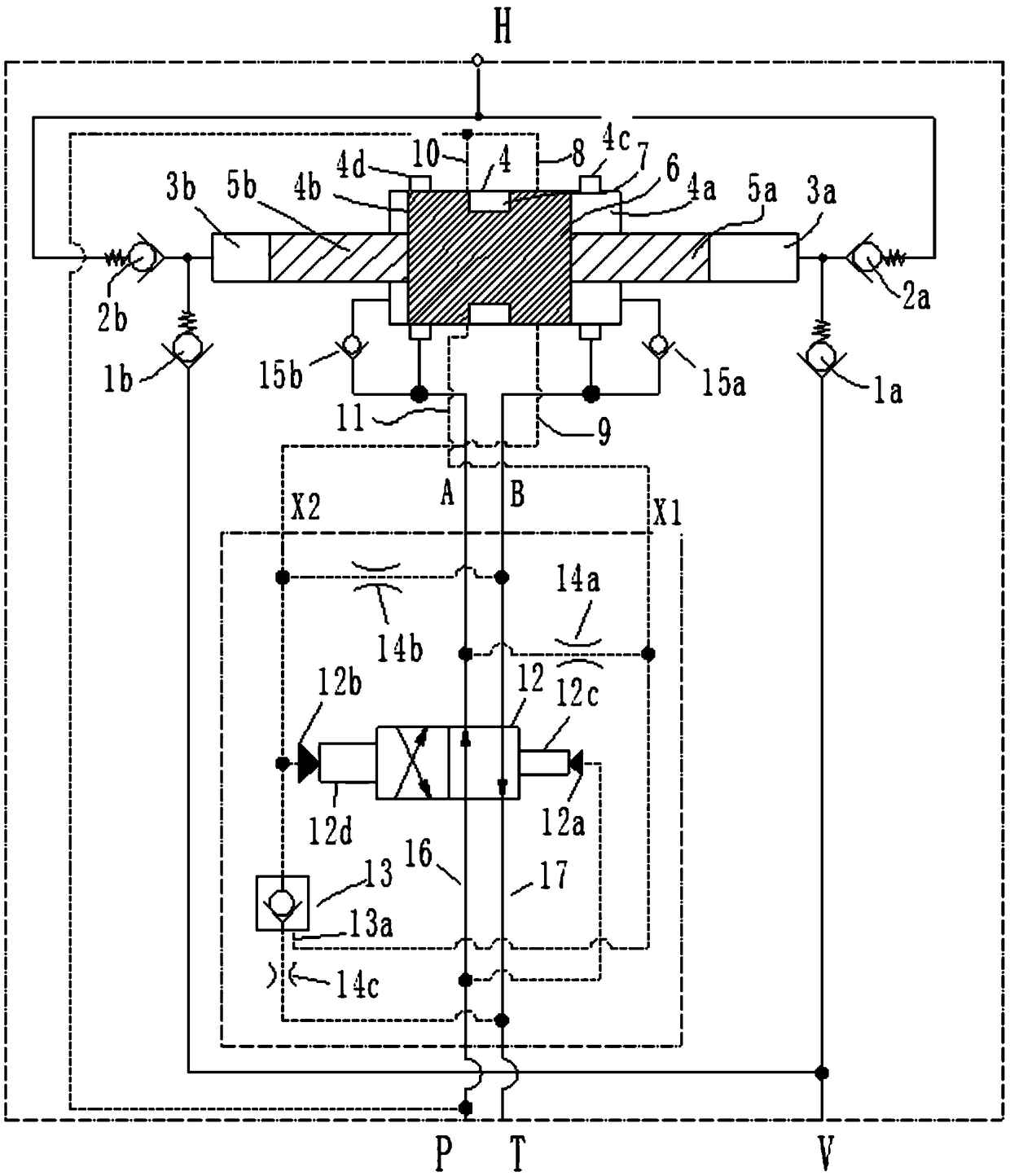

[0021] see Figure 1-3, which is a preferred embodiment of the present invention, the present invention provides a hydraulic mud pump, which is provided with an oil inlet P, an oil return port T, a slurry inlet V, and a high-pressure slurry outlet H, which includes a booster cylinder and a hydraulic control Reversing valve assembly; booster cylinder includes low-pressure cylinder 4, low-pressure piston 6, left high-pressure plunger 5b, right high-pressure plunger 5a, left high-pressure cylinder 3b and right high-pressure cylinder 3a, low-pressure piston 6 is slidably arranged in low-pressure cylinder 4 and A left piston cavity 4b and a right piston cavity 4a are respectively formed at its left and right ends, and its left and right ends are respectively slidably arranged with the left high pressure plunger 5b in the left high pressure cylinder 3b and the right high pressure plunger 5a in the right high pressure cylinder 3a. Connected, the low-pressure cylinder 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com