Slide-block type reversing clutch

A clutch and slider type technology, which is applied in the field of slider type reversing clutches, can solve the problems that the machine cannot work, the balls are easy to wear and lose the roundness, and the balls are not easy to achieve. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

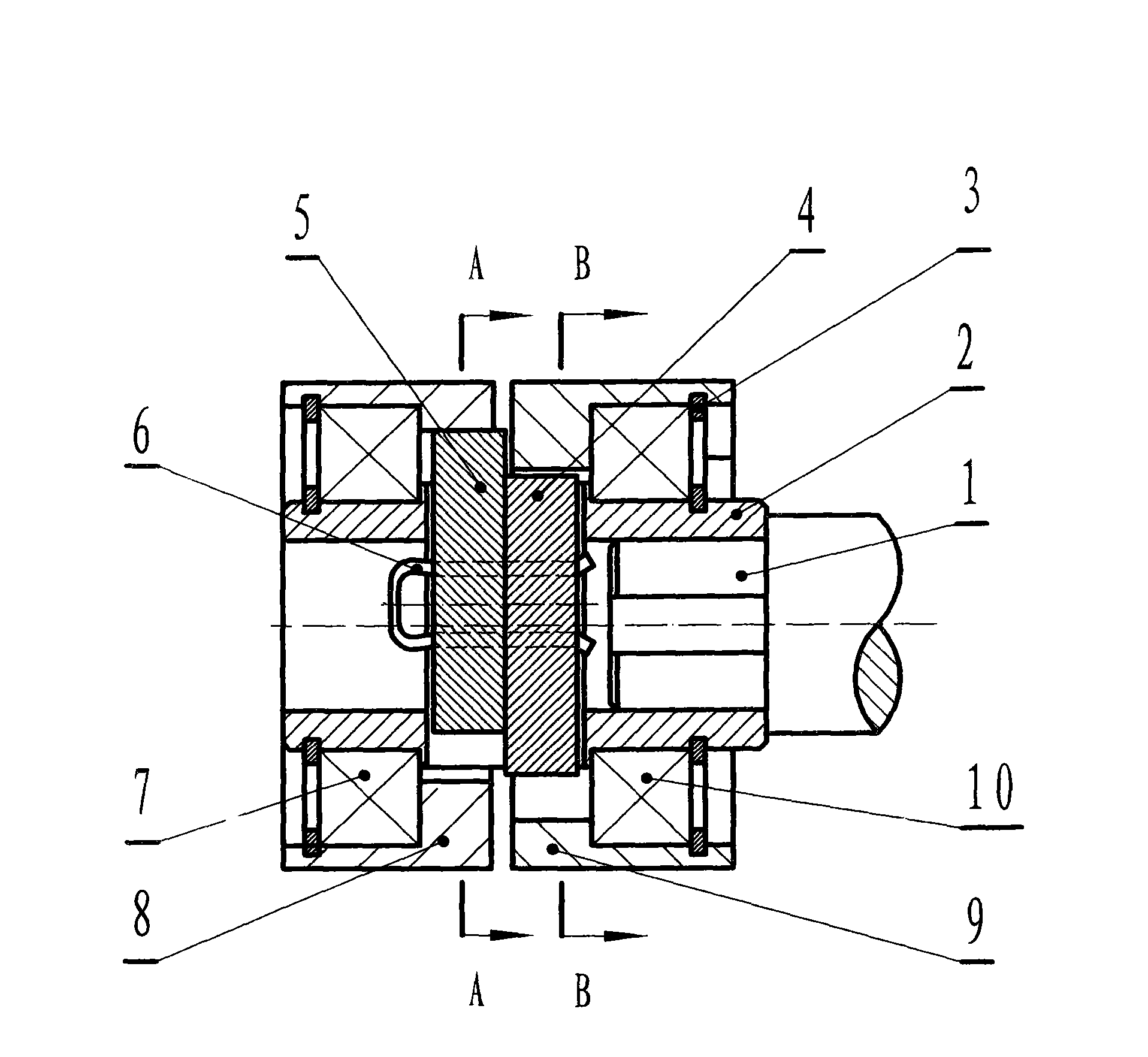

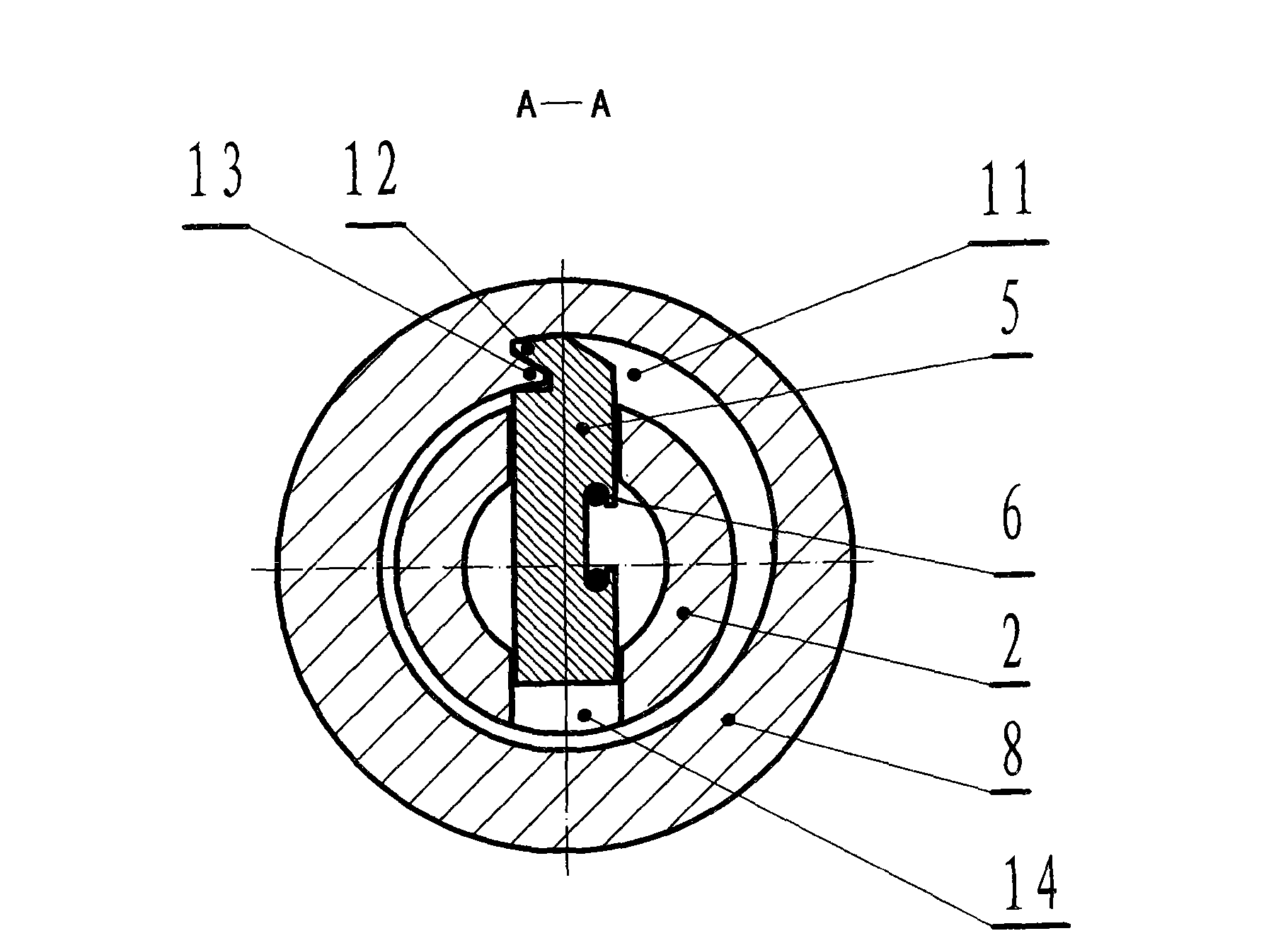

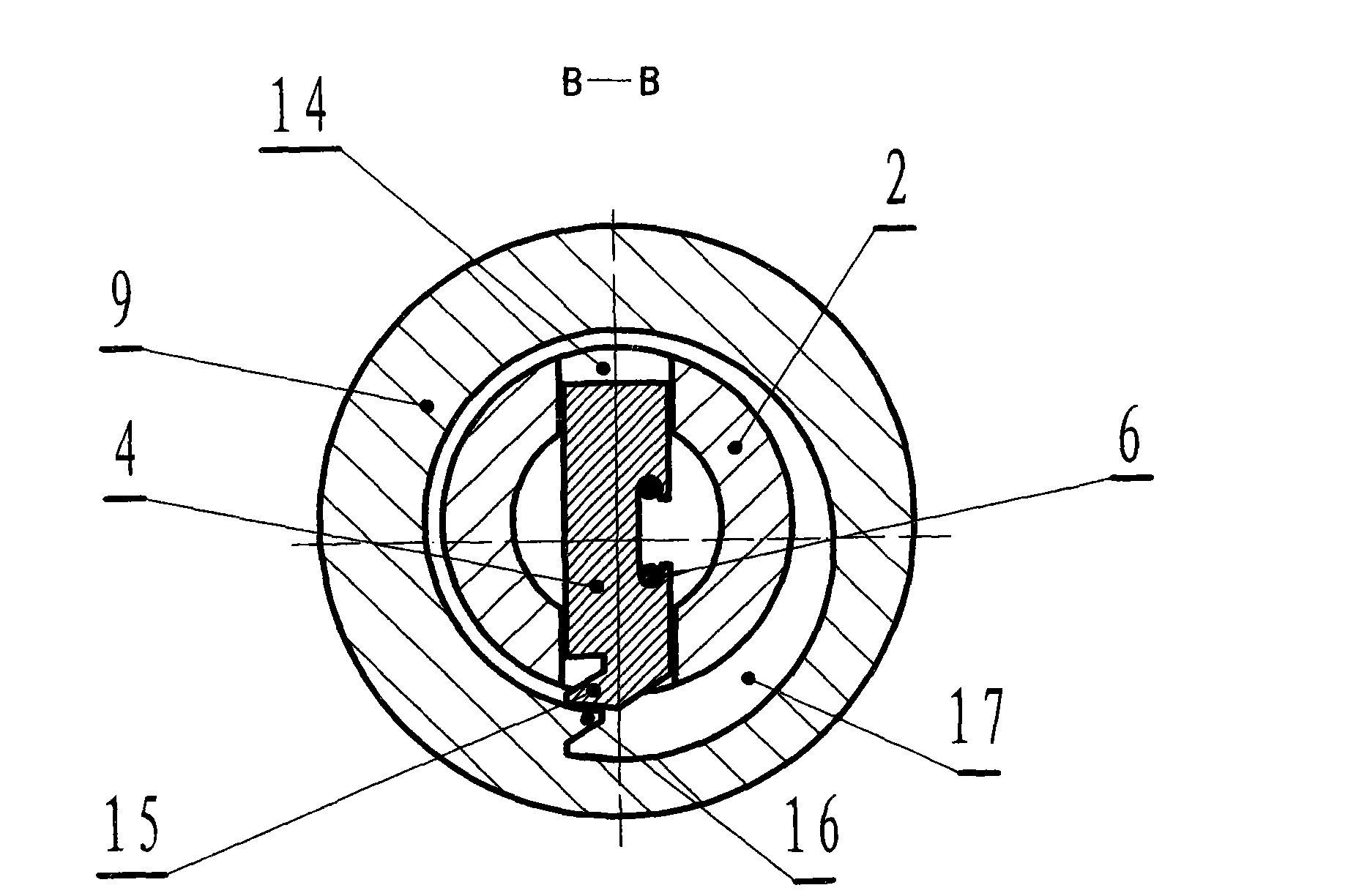

[0027] A slider-type reversing clutch with an inner sliding structure, which is mainly composed of a left pulley 8, a right pulley 9, bearings 7, 10, a shaft sleeve 2, and slider assemblies 5, 4, 6. The left pulley 8 , the right pulley 9 are respectively supported on the shaft sleeve 2 by bearings 7, 10, the bearings 7, 10 are axially positioned by the retaining ring 3, the shaft sleeve 2 is fixedly installed on the driving shaft 1 by the key 20, and the shaft sleeve 2 is made with a diameter To the through hole 14, the slider assembly 5, 4, 6 is slidingly fitted in the radial through hole 14 of the shaft sleeve 2, and the said slider assembly 5, 4, 6 is connected to the left slider by U-shaped spring 6 tension 5. The right slider 4 forms an integral structure. This structural design utilizes the elastic effect of the U-shaped spring 6 to play a good role in buffering and damping the left slider 5 and the right slider 4 when the reversing clutch moves. Effective reset effect, ...

Embodiment 2

[0029] A slider-type reversing clutch with an external sliding structure, which is implemented in the following manner: sliding slots 18, 19 are made on the slider assemblies 5, 4, 6, and the outer circle of the shaft sleeve 2 There is a section of flat square structure that is slidingly matched with the sliding long holes 18, 19, and the sliding long holes 18, 19 of the slider assembly 5, 4, 6 are slidably fitted on the flat side of the shaft sleeve 2 to form an external sliding type The reversing clutch structure enables the slider assembly 5, 4, 6 to slide on the flat side of the axle sleeve 2. And its other structures, working principles and working methods are the same as those described in the first embodiment. It can also well realize the purpose of using the driving shaft reversing to perform mechanical movement and power transmission clutch control proposed by the present invention.

Embodiment 3

[0031] A slider type reversing clutch is implemented in the following manner: said left drive wheel 8 and right drive wheel 9 are respectively made into a gear structure or a sprocket structure. And its other structures, principles and working methods are respectively the same as those described in Embodiment 1 or Embodiment 2. Can be respectively made into the sliding block type reversing clutch of internal sliding gear transmission or sprocket transmission and the sliding block type reversing clutch of external sliding gear transmission or sprocket transmission, all of which can realize the utilization of driving shaft reversing clutch proposed by the present invention. It has always been used for the purpose of mechanical movement and power transmission clutch control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com