Method for processing draining corrugated pipe using waste and old mulch film

A corrugated pipe and mulch technology, which is applied in recycling technology, plastic recycling, etc., can solve problems such as easy to rust during buried time, insufficient rigidity of corrugated pipes, and affect the use effect, so as to achieve low production cost, increase water-repellent ability and anti-corrosion Cushioning capacity and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Drainage bellows processed by waste mulch are made of the following raw materials by weight, which are melted and extruded by a plastic extruder: 76.5kg of modified waste mulch, 28kg of silicate mineral composition, 7.5kg of fly ash hollow microspheres , Antioxidant 1.8kg, coupling agent 4.2kg, lubricant 3.5kg, compatibilizer 3kg, colorant 0.3kg.

[0028] Wherein, the silicate mineral composition includes: kaolinite, montmorillonite, and zeolite, and the ratio of the three is 1:1:1.

[0029] The modified waste plastic film is obtained by melting and extruding the following components by weight through a plastic extruder: 100 parts of waste plastic film recycling particles, 8 parts of carbon black, 12 parts of talcum powder, 12 parts of calcium carbonate, diluent 3.5 parts, catalyst 1.2 parts.

[0030] The antioxidant is: 2,6-tertiary butyl-4-methylphenol, bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide or tetrakis [β-(3, 5-tert-butyl-4-hydroxyphenyl) propionate] penta...

Embodiment 2~3

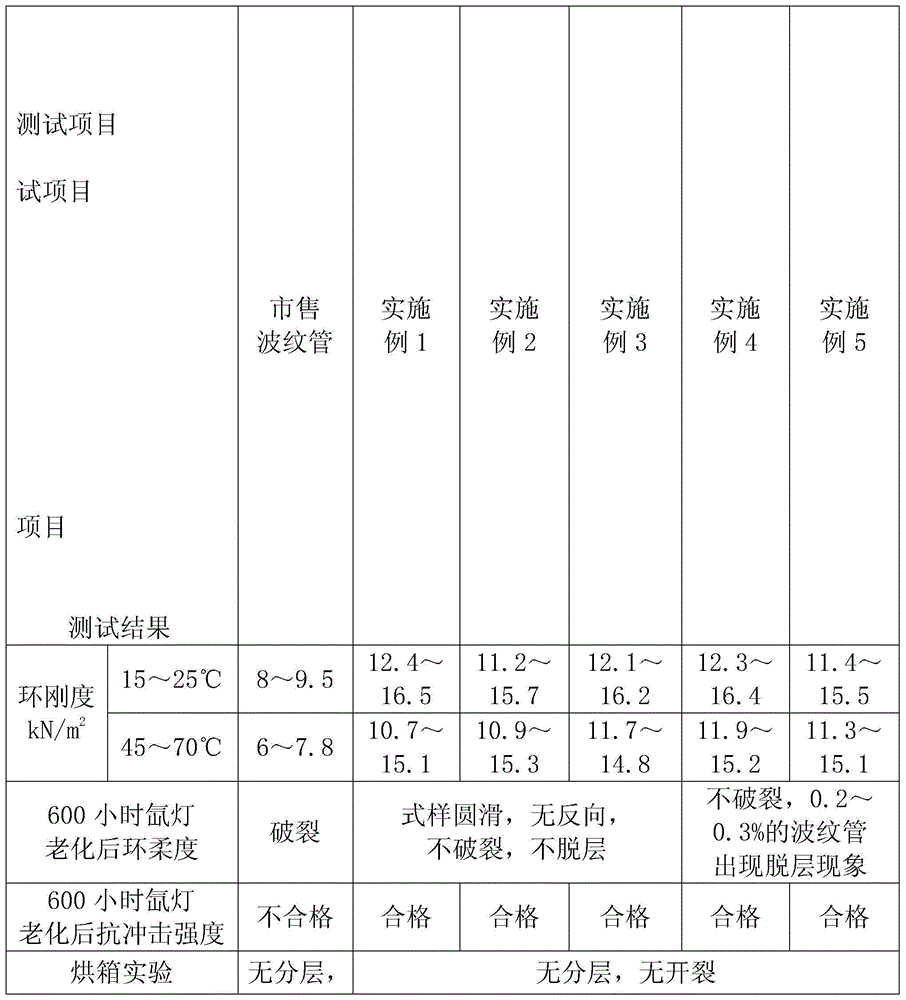

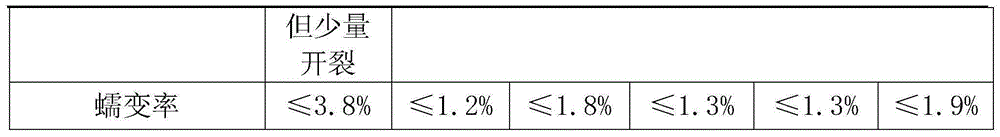

[0048] Drainage corrugated pipes processed by using waste plastic film are made of raw materials including the weight parts described in Table 1 below, and are made by melt extrusion through a plastic extruder:

[0049] Table 1 - Raw material ratio

[0050]

[0051] The test method of the ring stiffness of the polyethylene bellows prepared by the present invention refers to GB / T19472.1-2004, and the test method of the aging resistance is according to GB / T16422.2-1999, and then according to EN12608: 2002 test according to EN12608:2002 after illuminating the sample with a xenon light for 6000 hours The impact strength of the sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com