Hydraulic pressure automodulation pulling-type clutch release bearing assembly

A release bearing, self-aligning technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of easy wear at the contact point, difficulty in shifting gears, and high impact noise, and achieve no impact noise and separation. Smooth, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

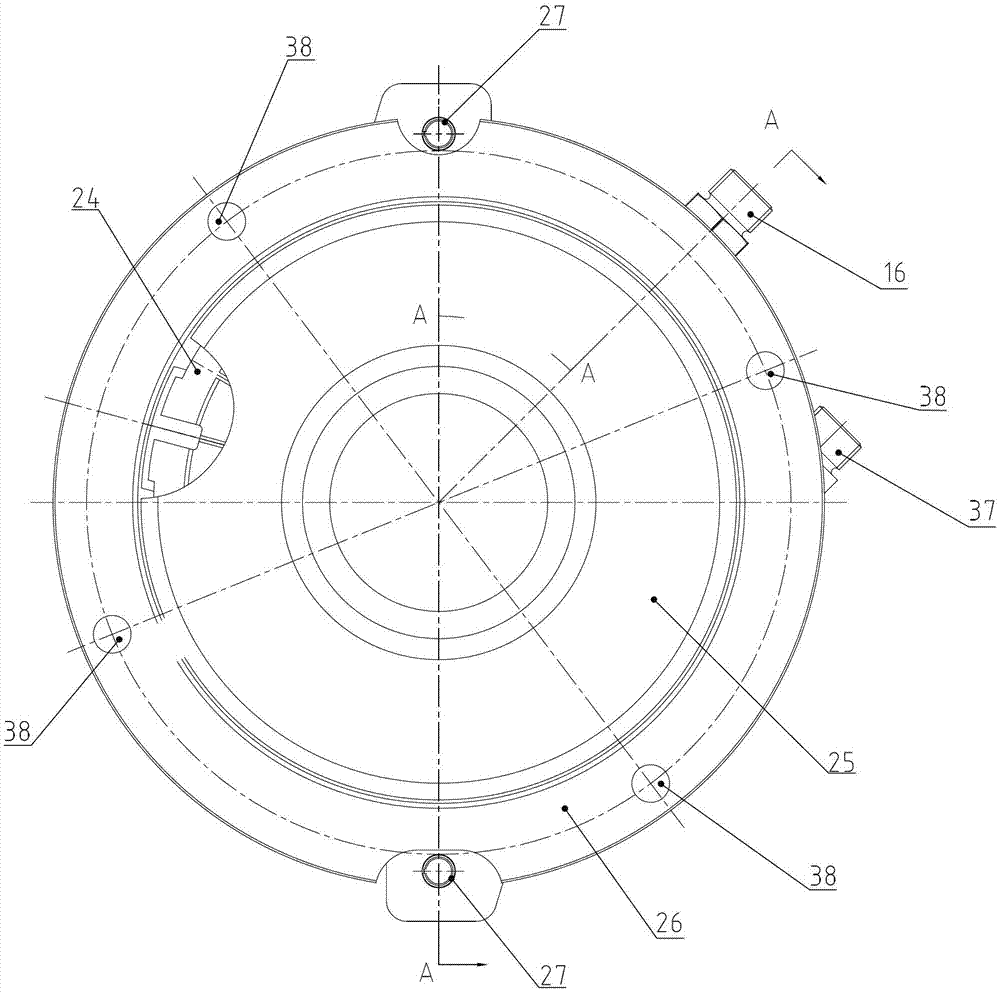

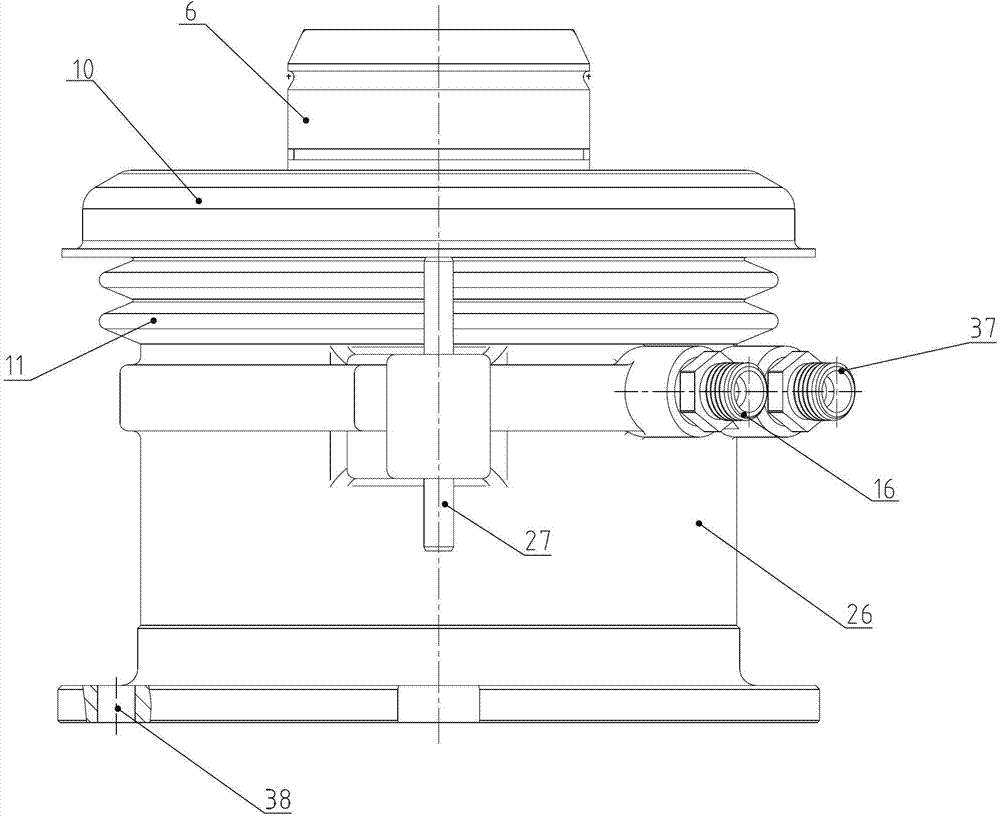

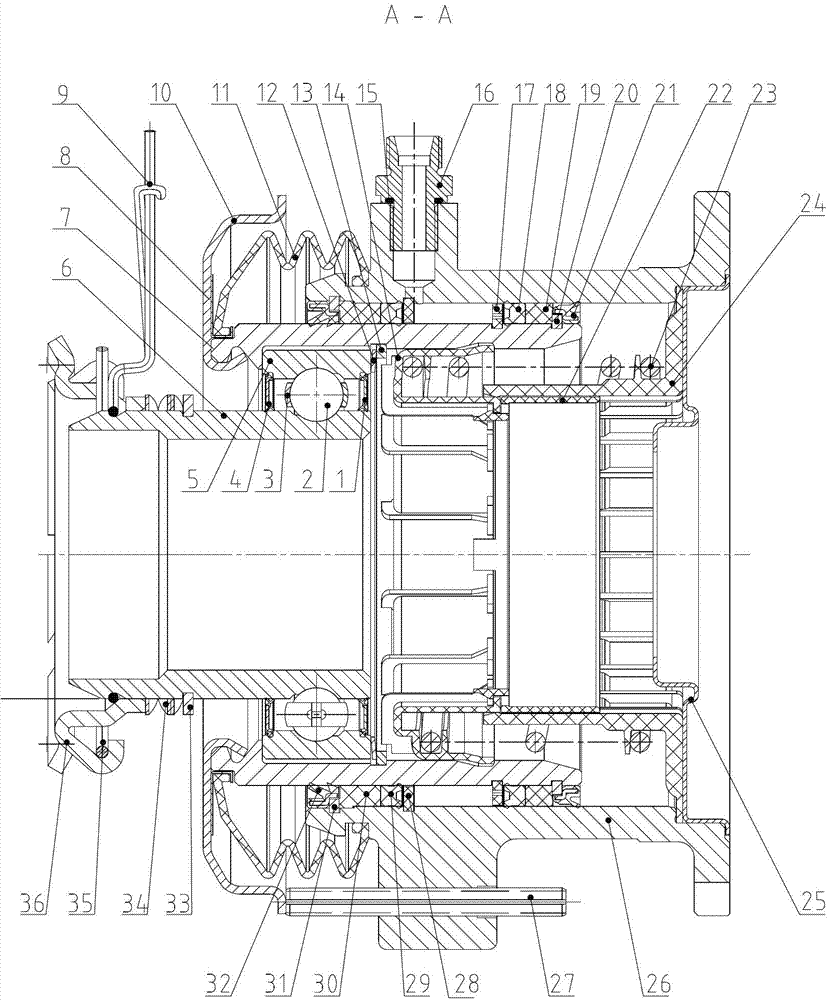

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0024] like Figure 1~3 As shown, the present invention mainly includes the piston 7 and the cylinder body 26, and the hydraulic cylinder oil cavity is formed between the inner circle surface of the cylinder body 26 and the outer circle surface of the piston 7. On the inner circle surface of the left end of the cylinder body 26, the cylinder body dustproof sealing ring 32, the cylinder body snap ring 31, the cylinder body plastic spacer 30, the cylinder body hydraulic sealing ring 29 and the cylinder body ring 28 are successively installed from left to right, and the cylinder body The outer circle of the body dust-proof sealing ring 32 is in interference fit with the inner surface of the cylinder body 26, and the inner lip of the cylinder body dust-proof sealing ring 32 is tightly pressed against the outer circle surface of the piston 7, which can effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com