Automatic hose cutting-off device

An automatic cutting and hose technology, which is applied in metal processing and other directions, can solve problems such as difficult speed, affecting production speed, noise pollution in processing environment, etc., and achieves continuous cutting, simple structure, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

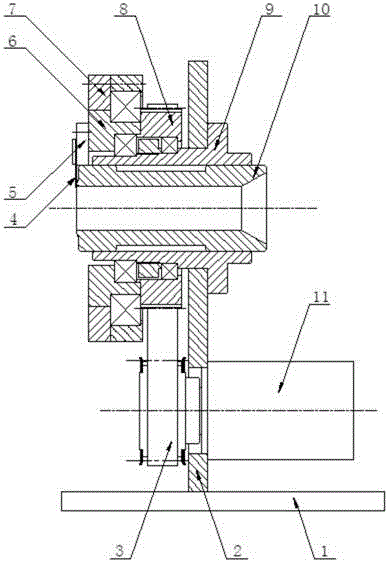

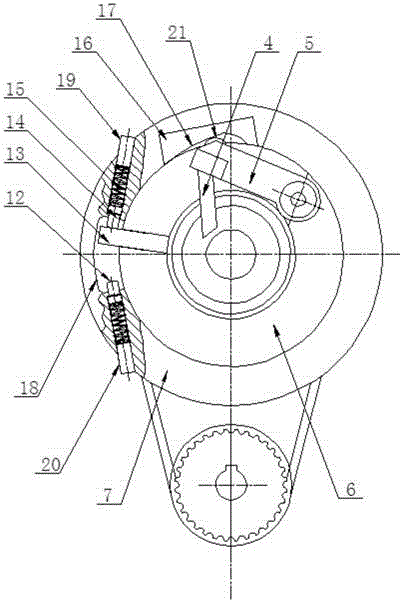

[0026] Such as Figure 1-2 As shown, an automatic hose cutting device includes a support frame, a transmission mechanism, a guide mechanism and a cutting mechanism, wherein: the support frame 1 includes a vertically arranged support plate 2, and a fixed sleeve 9 is worn on the support plate 2. The fixing sleeve 9 is used for the output channel of the extruded hose from the pipe making machine.

[0027] The transmission mechanism includes an inner moving ring 6 rotatably sleeved on the fixed sleeve 9 and an outer moving ring 7 rotatably sleeved on the inner moving ring 6. The transmission mechanism also includes a servo motor 11 fixedly arranged on the support plate 2 and connected to the inner The moving coil 6 drives the synchronous pulley 8 connected to it. The servo motor 11 drives the synchronous pulley 8 to rotate through the synchronous belt 3. The synchronous pulley 8 drives the inner moving coil 6 to rotate around the fixed sleeve 9. At the same time, the inner moving ...

Embodiment 2

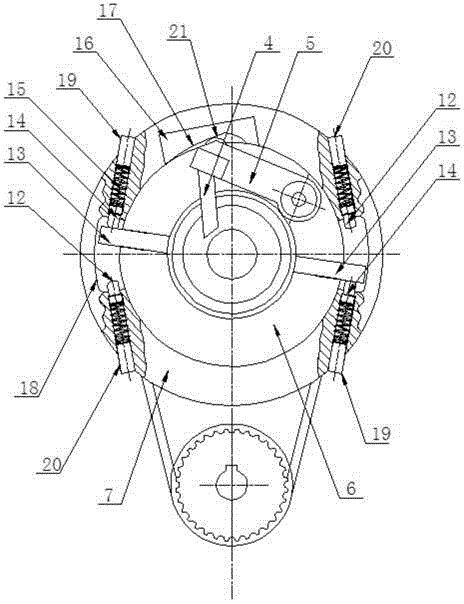

[0035] All the other are identical with embodiment, and difference is, as image 3As shown, in order to ensure the stability of the transmission, the limit bumper 13 of the inner moving coil 6 is symmetrically arranged, and a symmetrical limit groove is arranged on the position corresponding to the limit bumper 13 on the outer moving ring, and the inner moving coil drives When the outer moving coil rotates, the symmetrical use of the limit bumper to contact and drive the limit buffer head in the limit groove will make the device run more smoothly.

Embodiment 3

[0037] The rest are the same as in Embodiment 2, the difference is that a buffer layer is also provided on the outer surfaces of the front limit buffer head and the rear limit buffer head. When the head or the rear limit buffer head contacts, the buffer is further reduced, so that the automatic hose cutting device basically realizes the noiseless operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com