Rotation type air compressor

An air compressor and rotary technology, which is applied to rotary piston machines, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve the problem of large gas impact noise, low work efficiency, and no Output and other issues, to achieve the effect of ensuring the sealing effect, high work efficiency and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

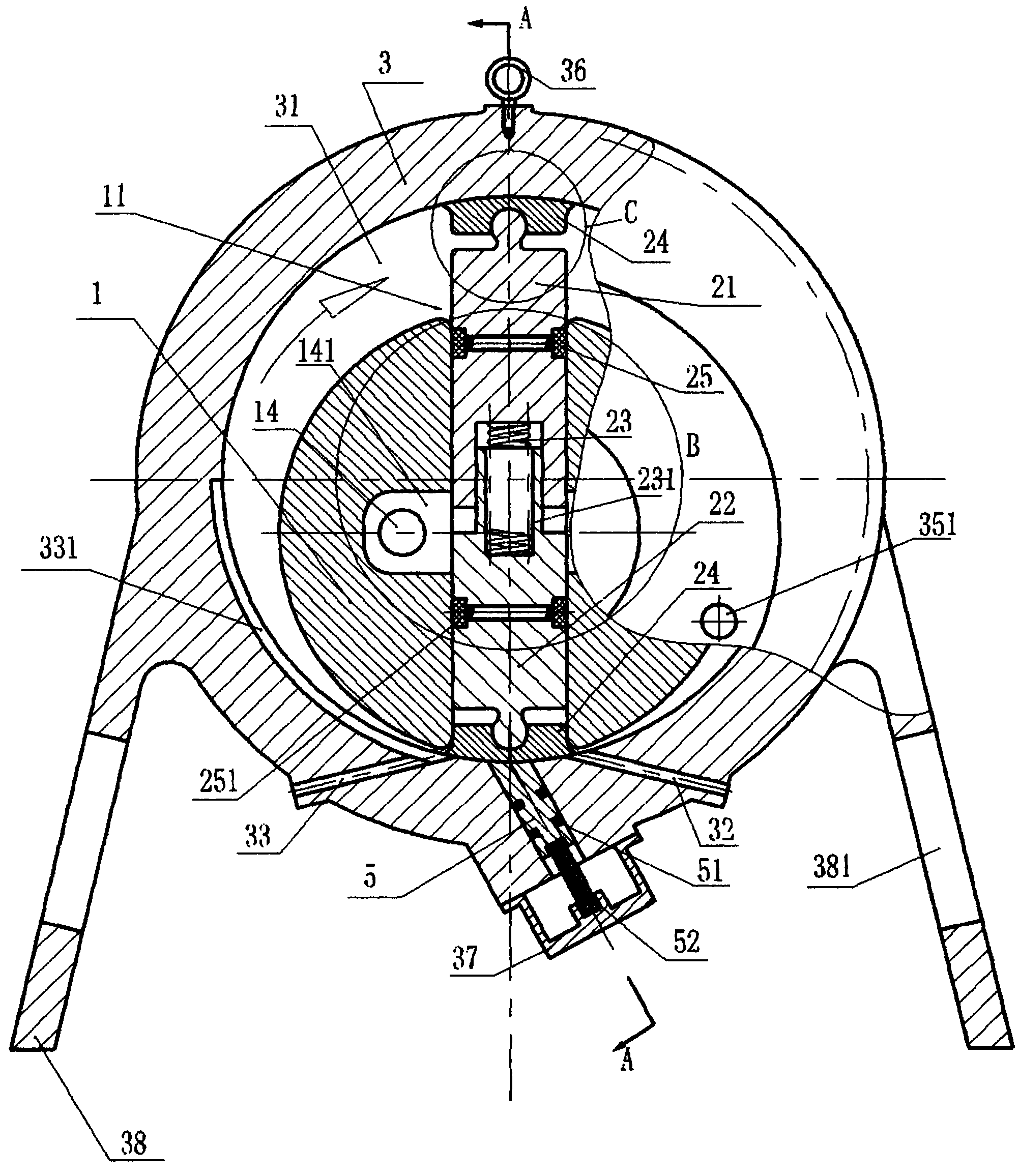

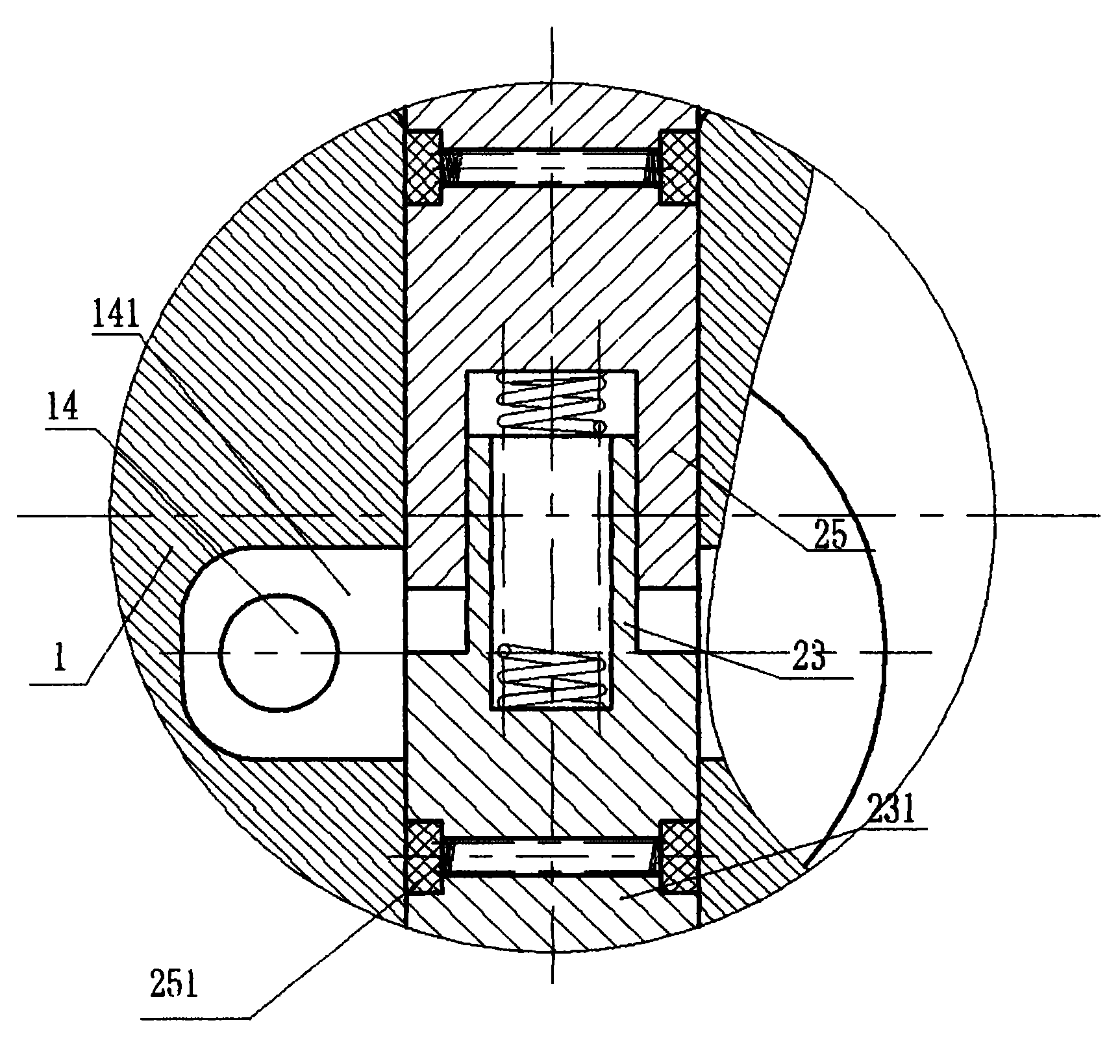

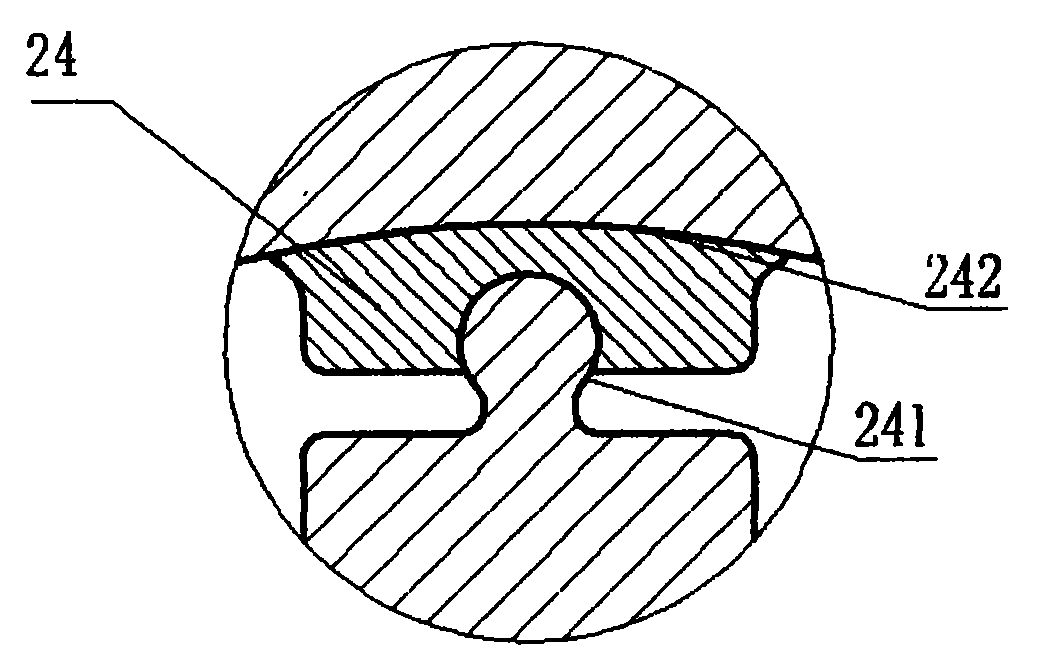

[0037] Such as figure 1 , 2, 8 are diagrams of two different embodiments of the rotary air compressor, the air compressor includes a rotor 1, a housing 3, an air inlet 33, an air outlet 32, and a gap between the rotor 1 and the housing 3 There is a casing cavity 31 that can compress air, and the rotor 1 is eccentrically arranged in the casing cavity 31. There is an airtight contact position between one side of the rotor 1 and the lower side of the casing cavity 31. The air inlet 33 and the air outlet 32 are respectively It is arranged on both sides of the airtight contact part, and the two ends of the housing cavity 31 are provided with end sealing devices; the rotor 1 is provided with a rotor slot 11, and a tongue device 2 that can reciprocate therein is provided in the rotor slot 11, the tongue The end of the tongue of the device 2 is always in airtight contact with the inner wall of the housing cavity 31 of the housing 3 , and can compress the gas in the housing cavity 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com