A liquid flow control valve

A technology for liquid flow and valve control. It is used in lift valves, valve devices, valve details, etc. It can solve problems such as low sensitivity, achieve high precision, reduce vibration and noise, and achieve large adjustment ranges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

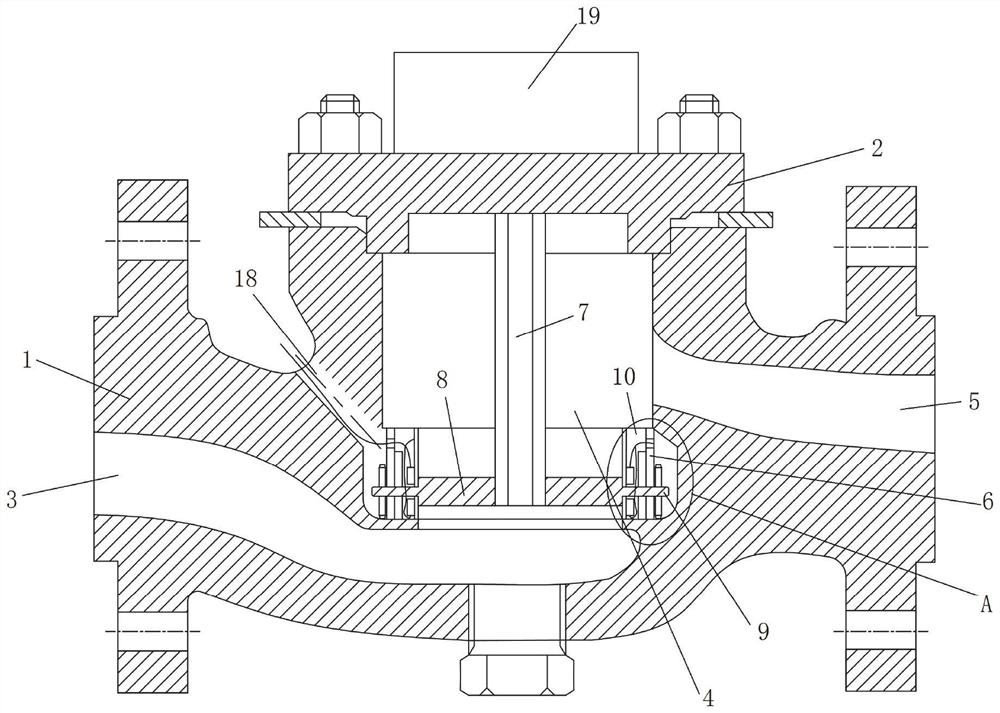

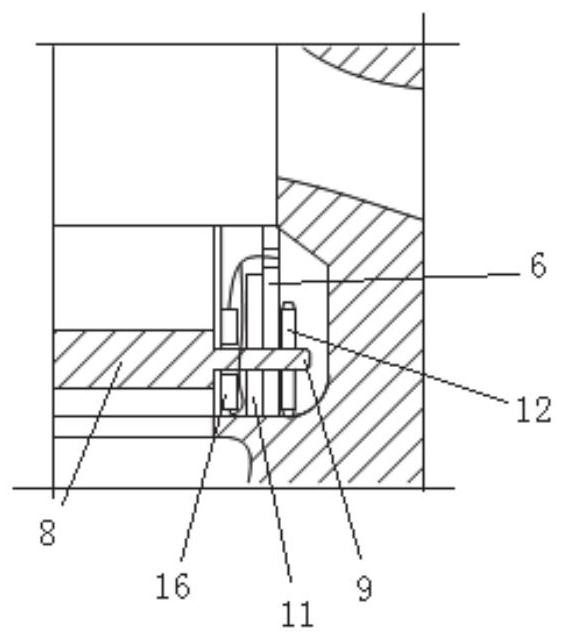

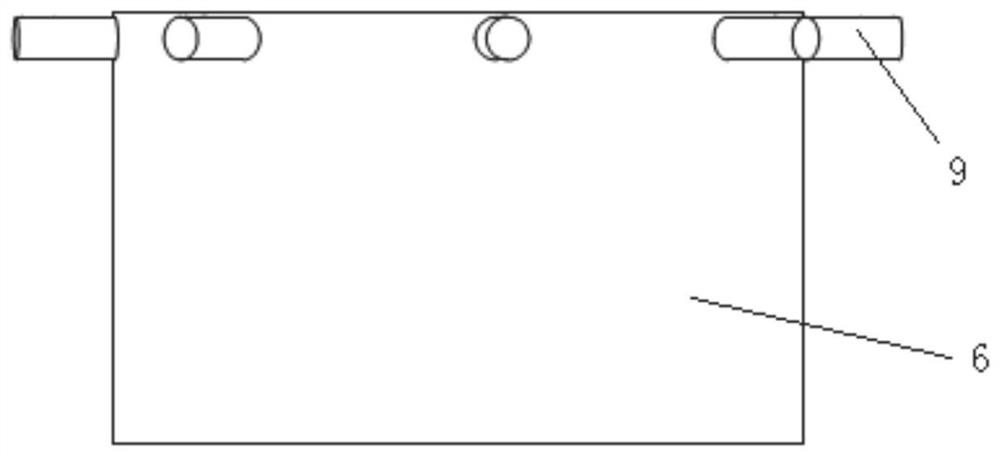

[0040] This embodiment provides a liquid flow control valve, such as Figure 1-Figure 2 As shown in the figure, it includes a valve body 1. The valve body 1 adopts a shell structure, the top of which is fixed with a valve cover 2 by bolts, and the two ends of the valve body 1 are provided with flange structures for connecting with pipelines. A flow channel is provided as a channel for liquid circulation. In this embodiment, the flow channel is composed of a first flow channel part 3, a second flow channel part 4 and a third flow channel part 5 arranged in sequence. The first flow channel The part 3 and the third flow channel part 5 are arranged horizontally, and the second flow channel part 4 is arranged vertically with the first flow channel part 3 and the third flow channel part 5 . The liquid can enter the flow channel from the first flow channel part 3 , pass through the second flow channel part 4 and then flow out from the third flow channel part 5 .

[0041] The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com