Butt joint technique for 10KV oil-paper insulated cable and cross-linked polyethylene insulated cable

A cross-linked polyethylene and insulated cable technology, applied in the field of power cables, can solve the problems of easy oil leakage of oil-impregnated paper insulated cables, affecting the operation of cross-linked cables, and pollution of cross-linked cables, so as to ensure the success rate and normal operation time. Long-lasting, pollution-avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

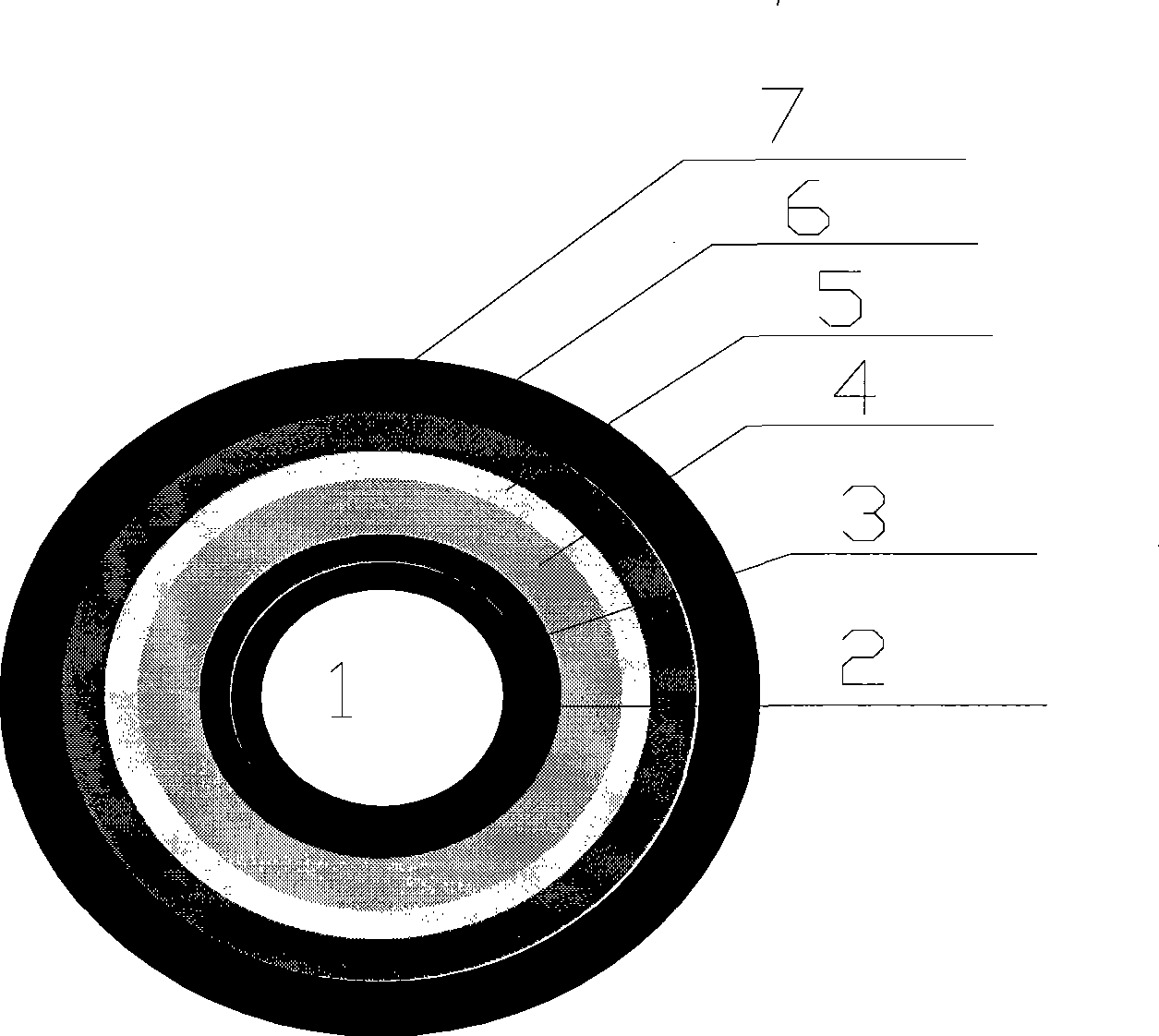

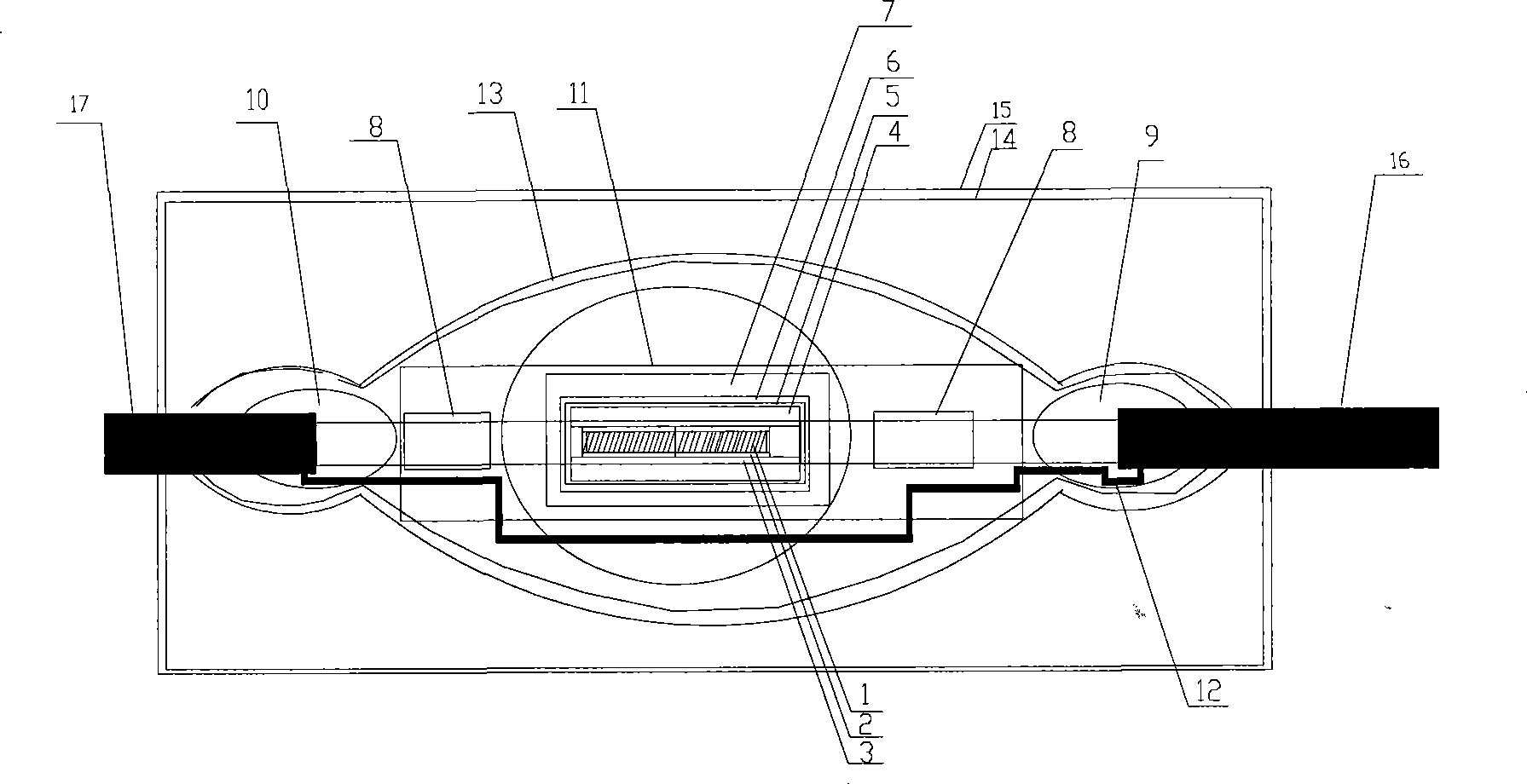

[0044] In order to realize the docking of 10KV power cable oil-impregnated paper insulated cable and cross-linked cable, it is necessary to realize the docking in two different insulating media: liquid insulation and solid insulation. To realize the docking of two cables, it must be done: 1. The sealing of the oil-impregnated paper insulated cable; 2. The electric field of the oil-impregnated paper insulated cable is evenly distributed; 3. The insulation recovery of the cross-linked cable; 4. The electric field of the cross-linked cable is evenly distributed; 5. 1. The uniformity of the electric field distribution when the two cables are connected.

[0045]The present invention adopts the following solutions respectively: 1. Utilize the heat-shrinkable cable to make the oil-resistant sealant in the cable head to realize the sealing of the oil-soaked paper insulated cable; 2. Utilize the heat-shrinkable cable to make the stress distribution pipe to realize the electric field of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com