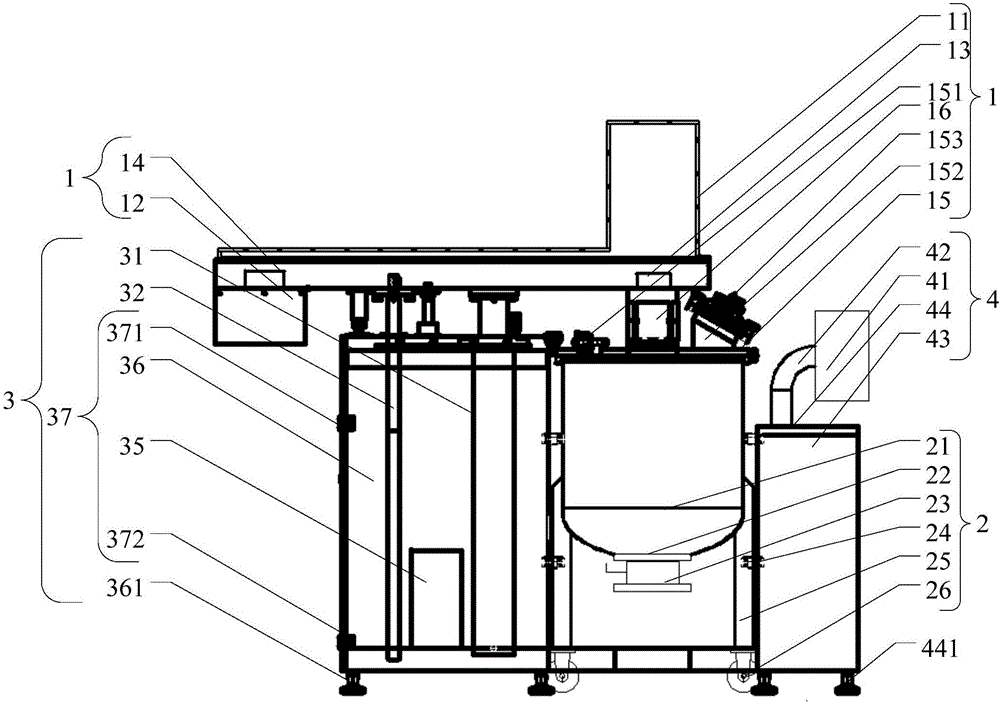

Wet material mixing machine

A technology for mixers and mixing equipment, which is applied in mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve problems such as leakage of materials, pollution, and incomplete discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

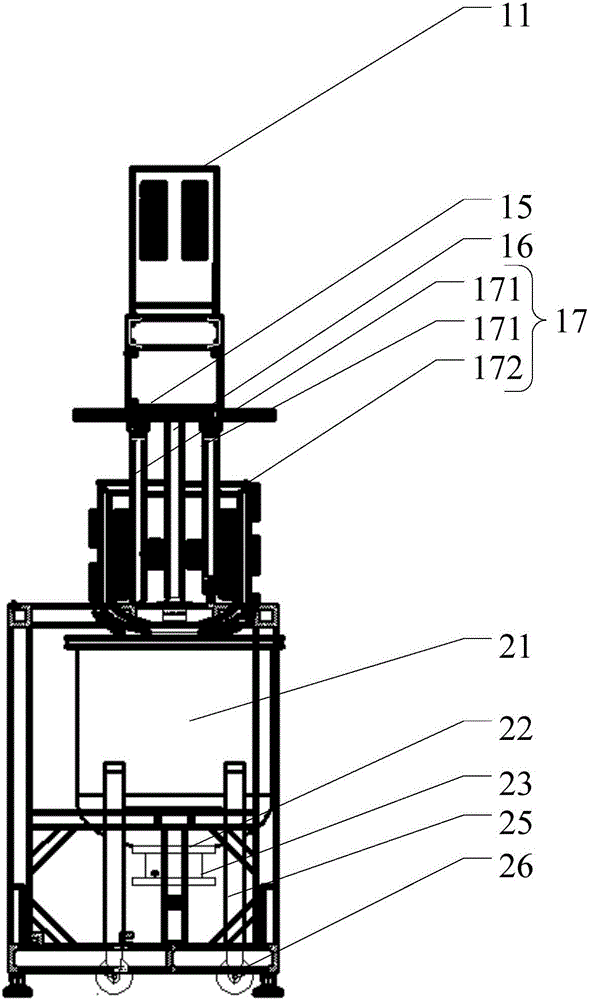

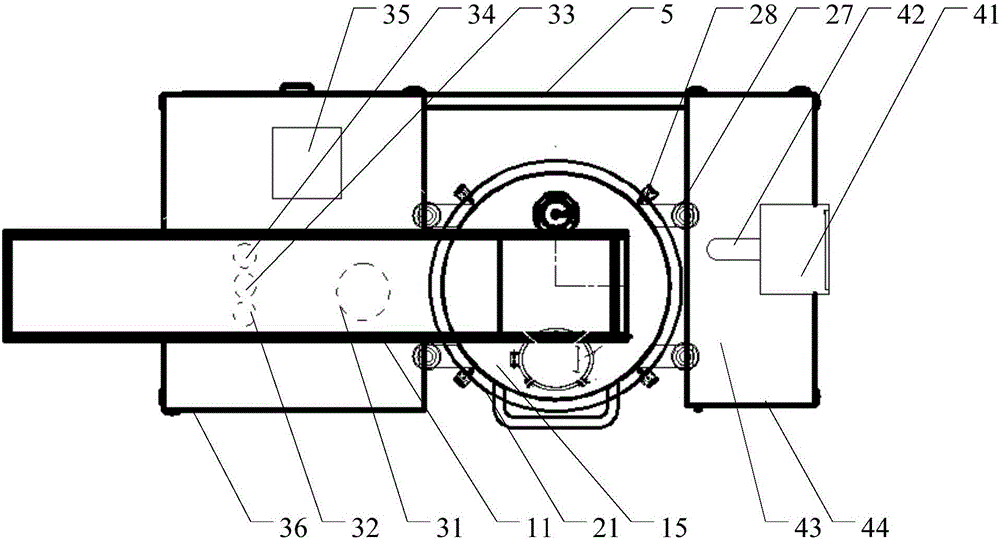

Method used

Image

Examples

Embodiment 1

[0186] When using a tidal material mixer in the present invention, first push the tank body in the mixing equipment into the area surrounded by the second cabinet, the connecting rod, and the first cabinet and then position it, that is, pass through the two sides of the tank body. The guide wheel on the side slides on the track corresponding to the outer wall of the second cabinet and the first cabinet, pushes the tank body into the area surrounded by the second cabinet, the connecting rod, and the first cabinet and then fixes it. The second proximity switches on the corresponding outer walls of the second cabinet and the first cabinet are positioned. When the positioning of the tank body is inaccurate, when the tank body is stirring, the second proximity switch is triggered to send a stop stirring signal, and the stirring reducer receives the stop stirring signal, and stops driving the stirring motor to stir.

[0187] Then take the materials for the preparation of Shexiang Ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com