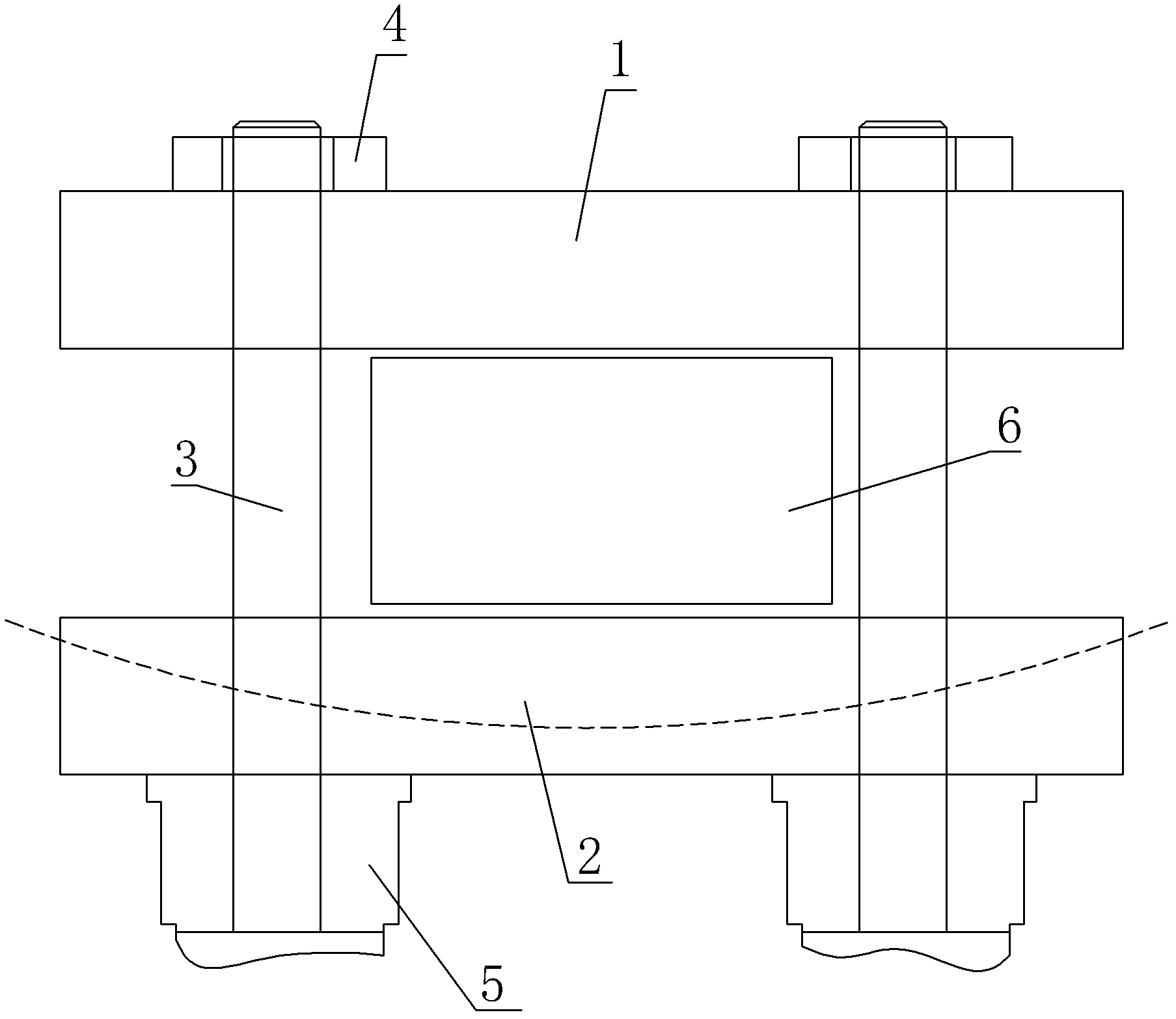

Mould-clamping oil cylinder device

A technology of clamping cylinder and guide ring, applied in the direction of fluid pressure actuating device, etc., can solve the problems of clamping cylinder failure, sealing damage of clamping cylinder, strain, etc., and achieve the effect of not easy oil leakage and large buffer space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

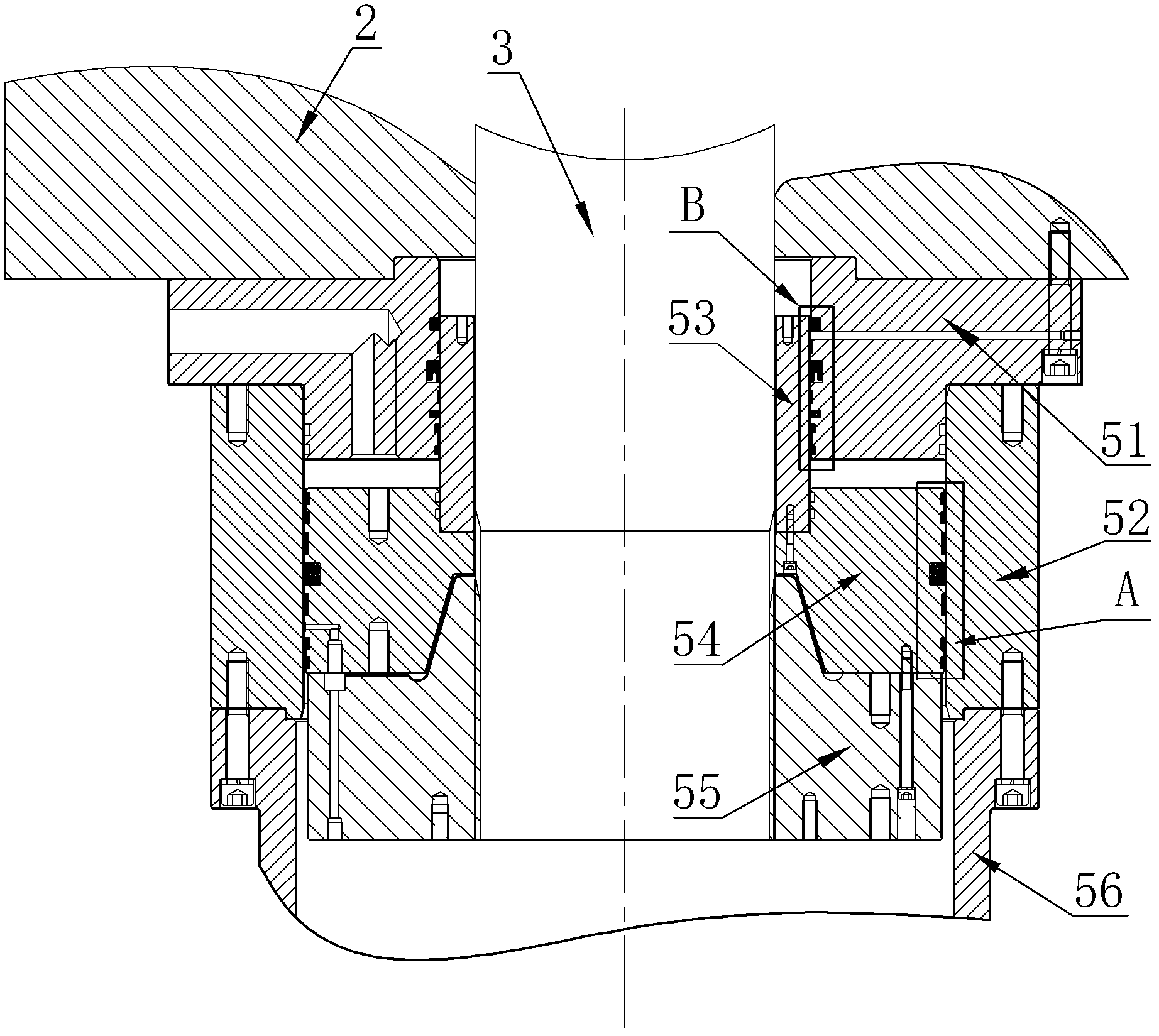

[0039] like figure 2 As shown, the main structure of the clamping cylinder device of the present invention still includes a cylinder 52, a front end cover 51 connected to the front end of the cylinder 52 by screws, a piston rod 53 sleeved on the pull rod 3, and a piston connected to the piston rod 53 by screws. 54, and the main nut 55 that is connected to the tail end of the pull rod 3, and the connection cover 56 that is connected to the rear end of the cylinder barrel 52 by screws.

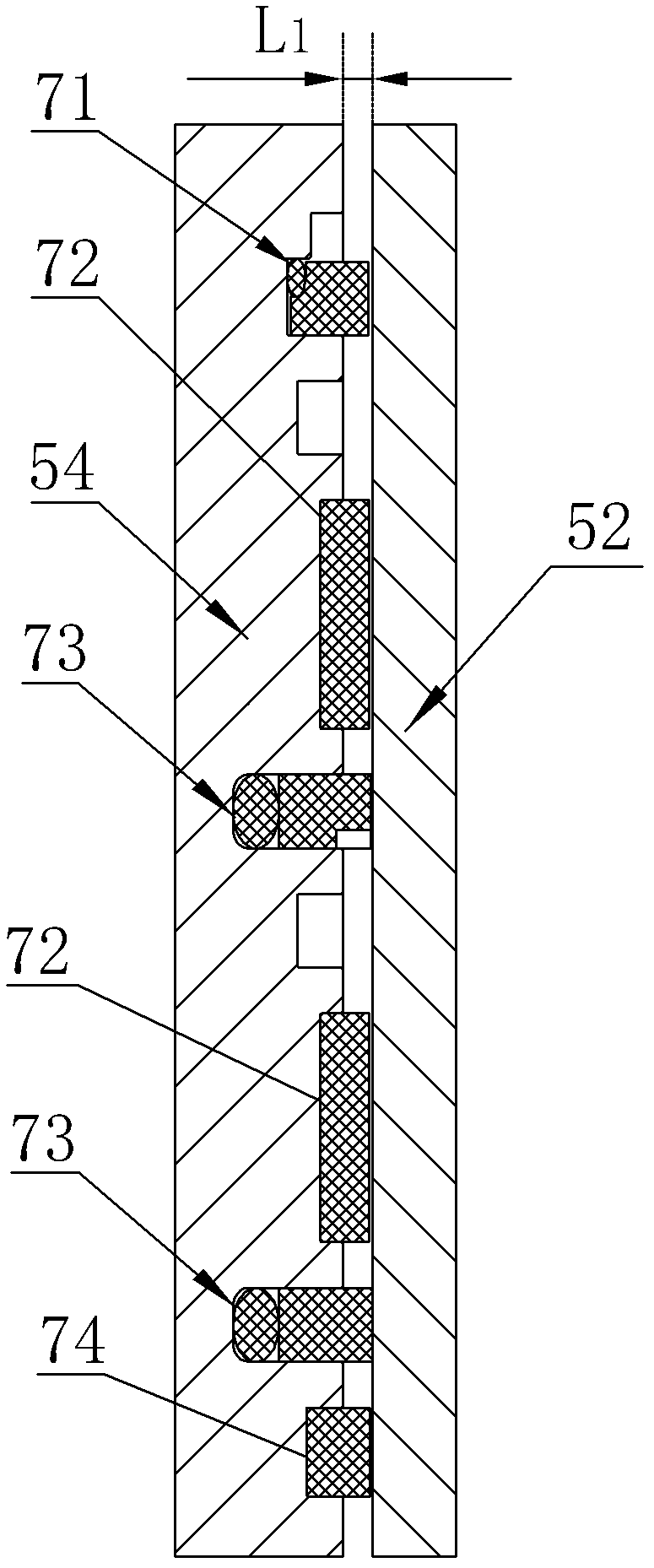

[0040] like Figure 4 As shown, a first guide ring 71 and a second guide ring 74 are respectively provided on the outer circumferential wall of the piston 54 close to the upper and lower end faces, and a first sealing ring 73 is provided in the middle of the outer circumferential wall of the piston 54; Increase the distance between the piston 54 and the cylinder 52 and ensure that the guide ring is not easy to fall off. In this embodiment, a special first guide ring 71 and a second guide ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com