Multi-runner Coriolis mass flowmeter sensor fluid main part

A mass flow meter, Coriolis technology, applied in the field of fluid main components, can solve the problems of high sensitivity and small environmental impact, and achieve the effect of high sensitivity, small environmental impact and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

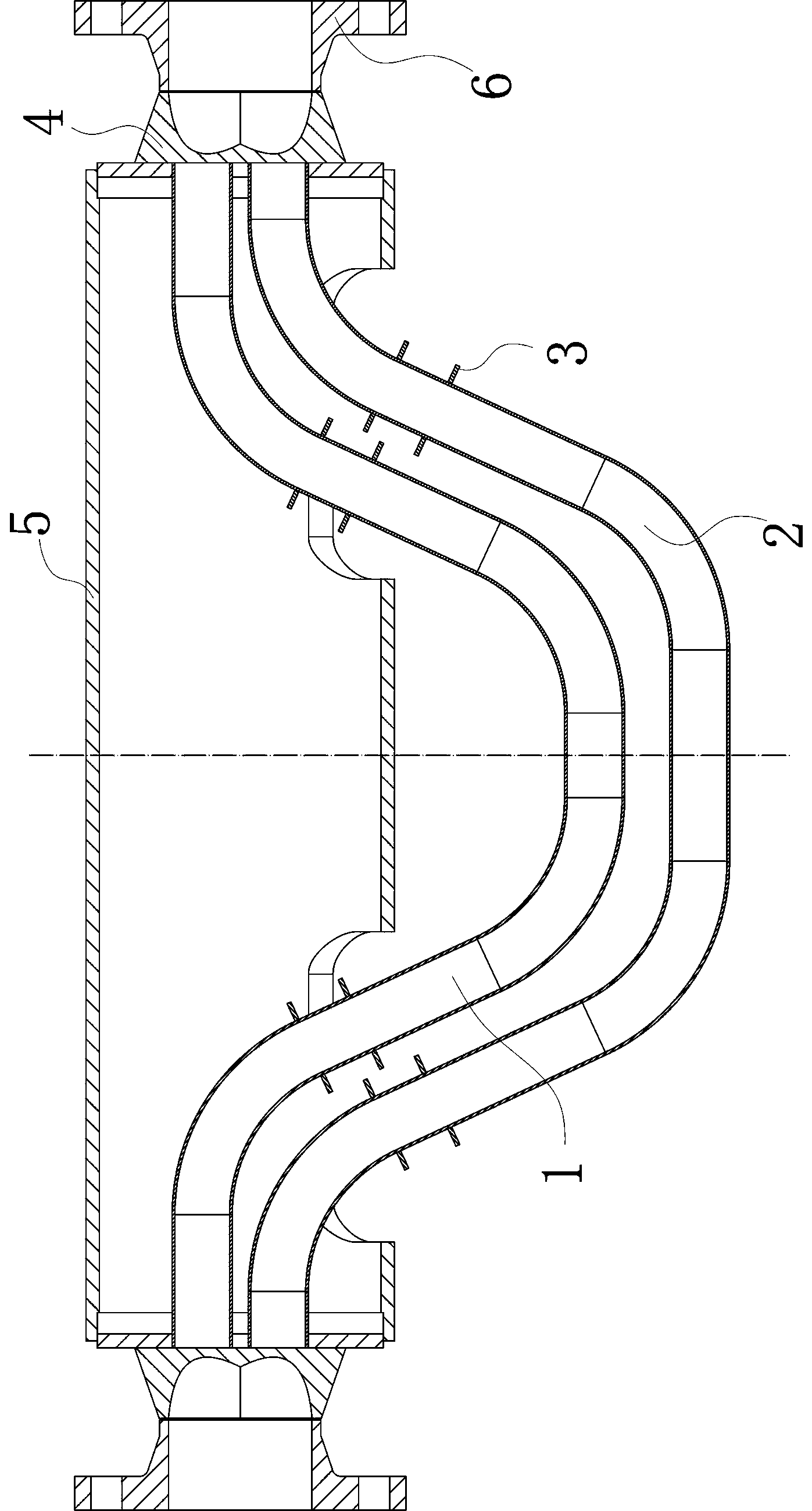

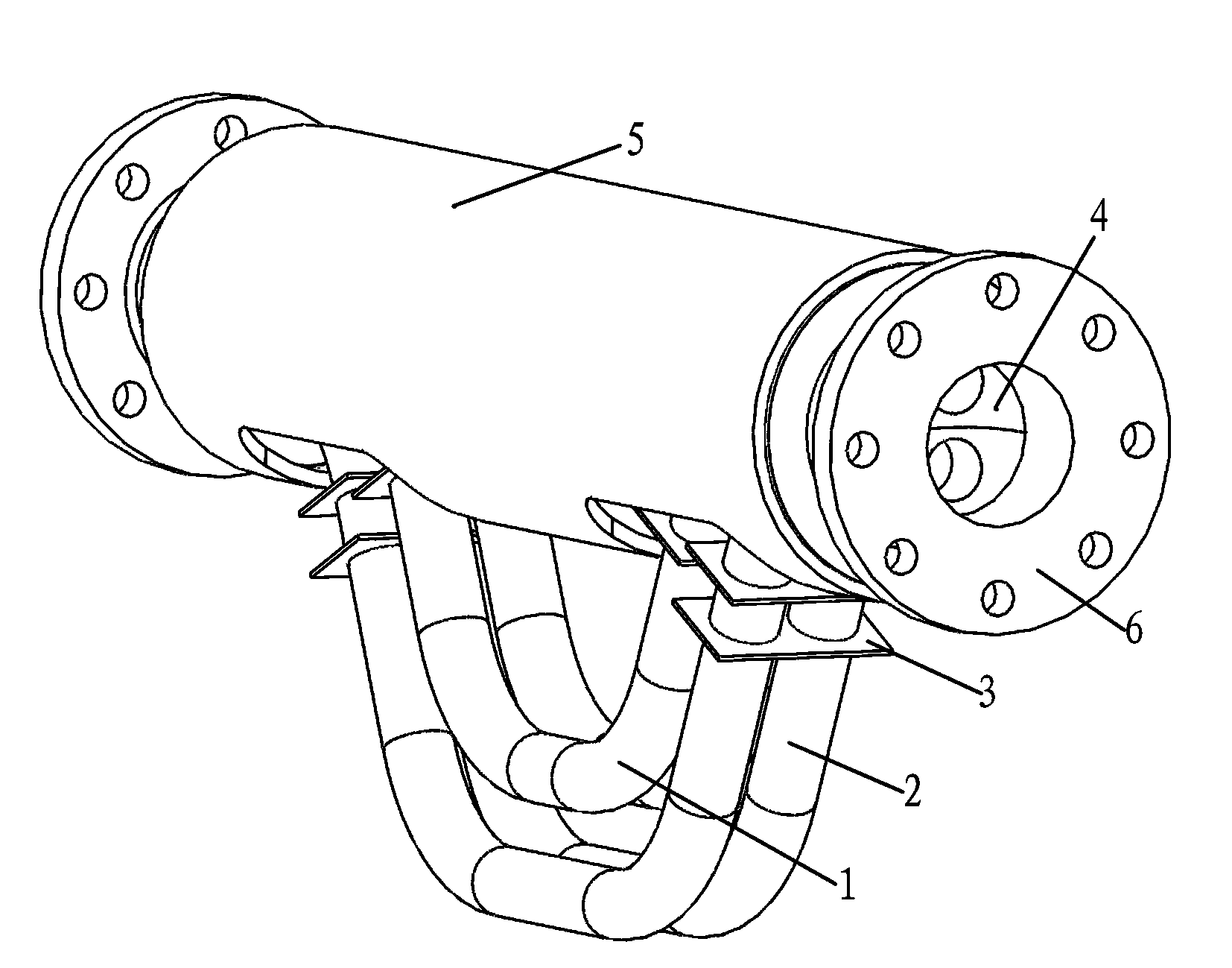

[0012] refer to figure 1 with figure 2 , the present invention includes a flow tube, a support tube 5 , a sub-body 4 and a connecting flange 6 .

[0013] The flow tubes are U-shaped micro-bent tubes, two of which form a group, and each group has the same shape. The two sets of flow tubes are installed up and down, and are divided into upper and lower groups, that is, upper flow tube 1 and lower flow tube 2. The upper flow tube 1 and the lower flow tube 2 have an included angle of 115 degrees formed by the centerlines of the horizontal pipe and the inclined pipe, and the horizontal pipe and the inclined pipe are curved with a smooth transition.

[0014] At least one damping plate 3 is jointly fixed on the outer walls of the two inclined straight tubes on both sides of the upper flow tube 1 and the lower flow tube 2 . In this embodiment, at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com