Mono bearing one piece core solenoid

a solenoid and mono bearing technology, applied in the field of solenoid valves, can solve the problems of contaminants in transmission fluid generated by metal particles, and contaminants can often become lodged within the solenoid valve, and achieve the effect of enhancing the flow density of the solenoid valv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

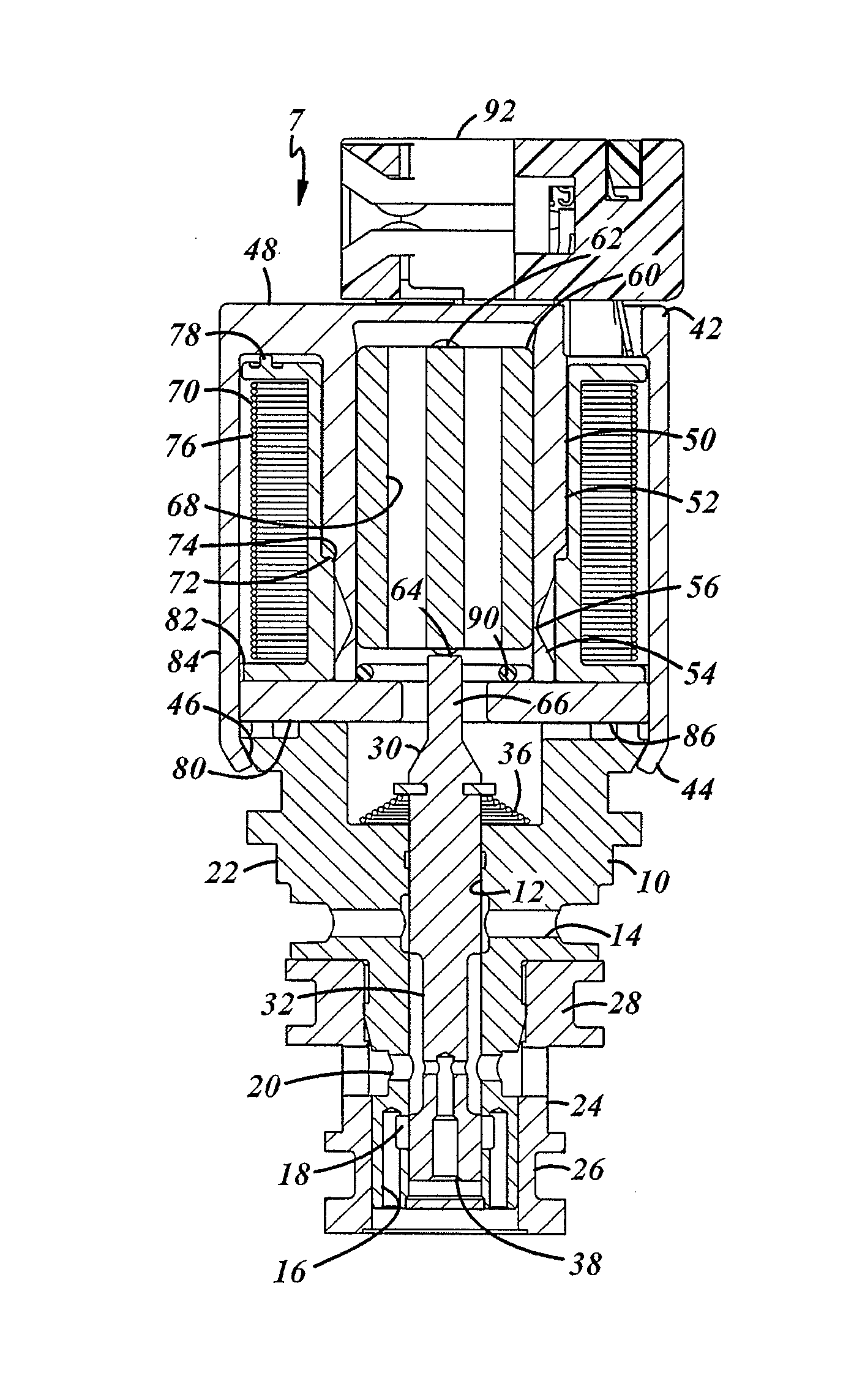

[0013]Referring to FIG. 1, an immersable solenoid valve 7 according to the present invention can have a valving member including a hydraulic body 10. The hydraulic body 10 has an axial generally tubular passage 12. The hydraulic body 10 has a transverse cross bore 14 for connection with exhaust pressure or a sump. The hydraulic body 10 additionally has a series of non-concentric axial bores 16 which intersect an enlarged diameter portion 18 to provide a fluid path which is connected with supply pressure. A multi-dimensional cross bore 20 is provided for inlet / outlet connection with a desired control pressure. The hydraulic body 10 has a metallic primary body 22 and has a lower tip covered by an outer sleeve member 24 having annular grooves 26 and 28 for placement of sealing members (not shown).

[0014]Slidably mounted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com