Electronic Temperature Compensated Rotameter

A rotameter, electronic temperature technology, applied in the direction of volume change compensation/correction device, volume/mass flow generated by mechanical effects, etc., can solve the problems of large error in output data and cannot meet the accuracy requirements of measurement, etc., to achieve high The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

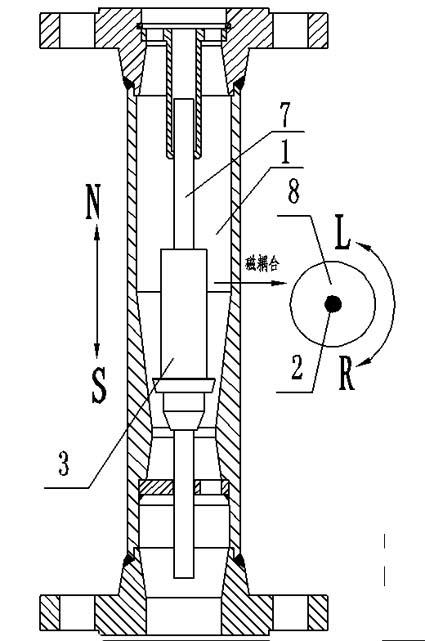

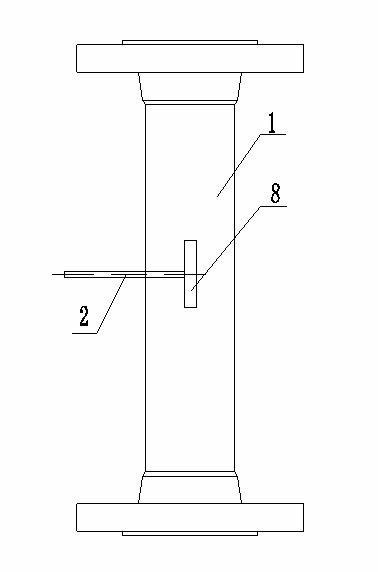

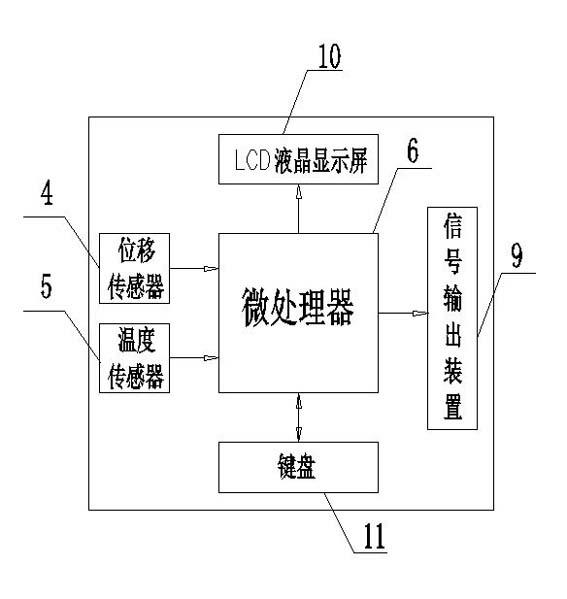

[0025] like figure 1 , figure 2 The shown electronic temperature compensated rotameter includes a flow tube 1 with a tapered lumen, a first guide rod 7 set through the flow tube 1 , and a float set in the tapered lumen of the flow tube 1 3. The float 3 is fixedly set on the first guide rod 7. The above-mentioned float flowmeter also includes a displacement sensor 4, a temperature sensor 5 for sensing ambient temperature, a microprocessor 6, an angular displacement sensor 4, The temperature sensor 5 outputs the angular displacement signal and the temperature signal to the microprocessor 6 respectively.

[0026] The above-mentioned magnetic coupling force is provided by a built-in magnet built into the float 3 ( figure 1 Mark the magnetic poles of the float 3, N and S), a second guide rod 2 arranged outside the flow tube 1 and perpendicular to the first guide rod, and a fixed circular ring sleeved at one end of the second guide rod 2 A magnetic coupling system composed of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com