Magnetic flowmeter with coil ground path detection

一种磁流量计、线圈的技术,应用在测量流量/质量流量、测试/校准体积流量、测量装置等方向,能够解决线圈驱动信号不能检测、不精确流量测量、EMF减小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

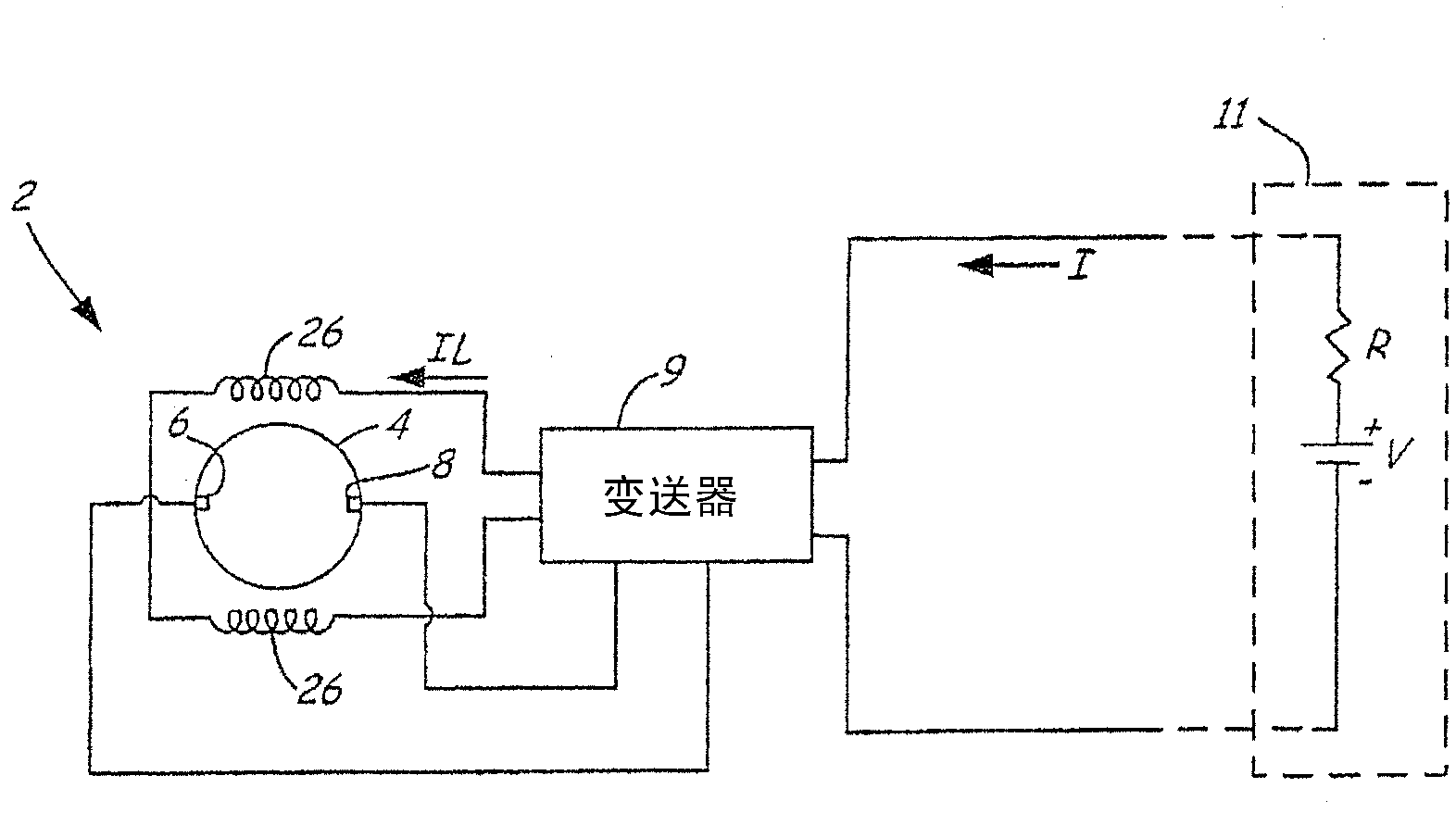

[0012] exist figure 1 , the magnetic flowmeter system 2 is connected to a two-wire communication 4-20mA loop carrying current I and to an AC power line (not shown). Flow tube 4 carries the fluid flow. Transmitter 9 provides coil drive current I to coil 26 adjacent to flow tube 4 L , the coil 26 generates a magnetic field in the fluid. Electrodes 6, 8 are mounted in the flow tube 4 along lines perpendicular to the magnetic field in the fluid for sensing EMF induced by the fluid flow. The transmitter 9 senses the EMF between the electrodes 6, 8 and controls a DC output current I representative of the sensed EMF, which is proportional to the fluid flow. Transmitter 9 sends current I to remote receiving station 11 on a 4-20mA current loop. Transmitter 9 may also send flow output in digital form using HART digital protocol, Fieldbus protocol, wireless protocol, or other technologies.

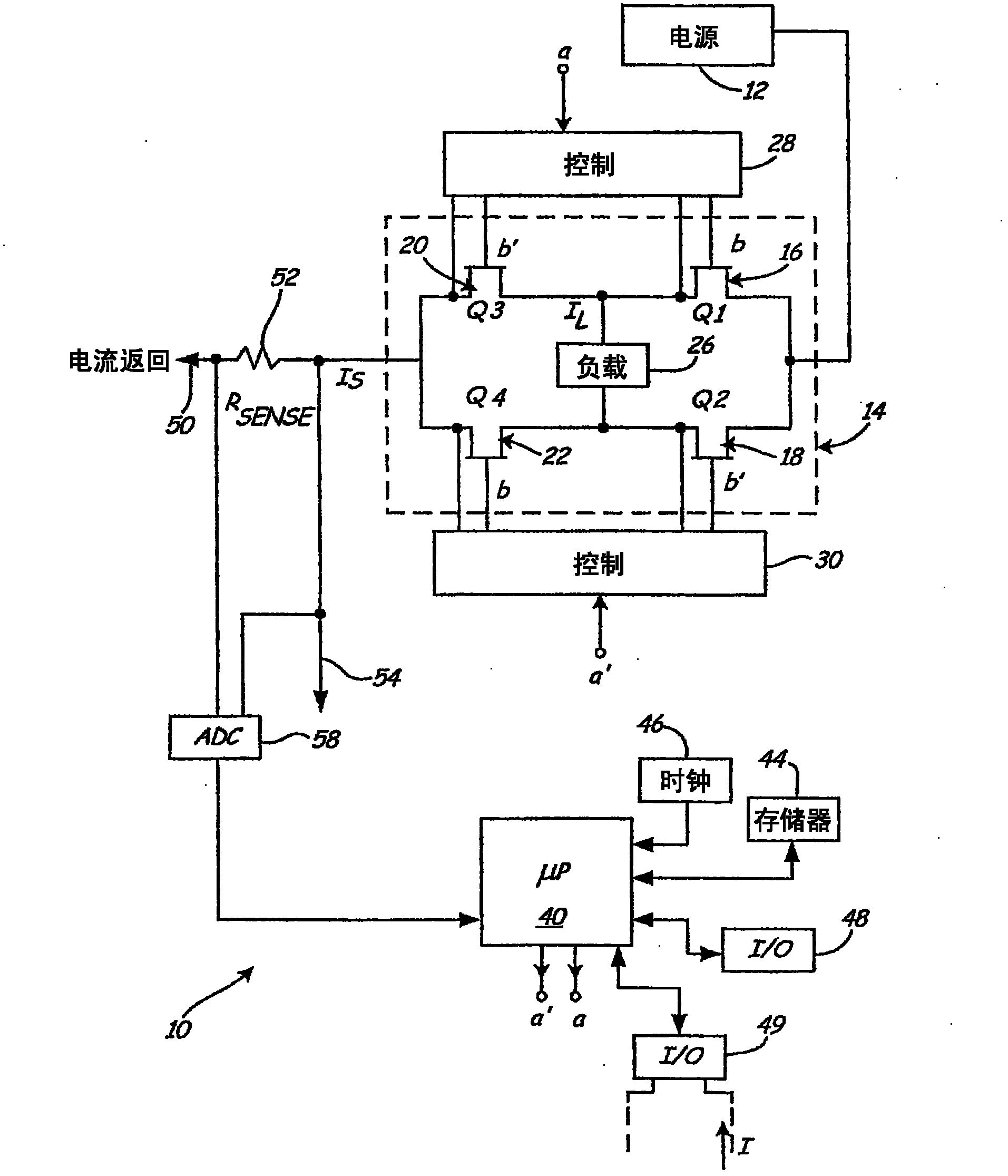

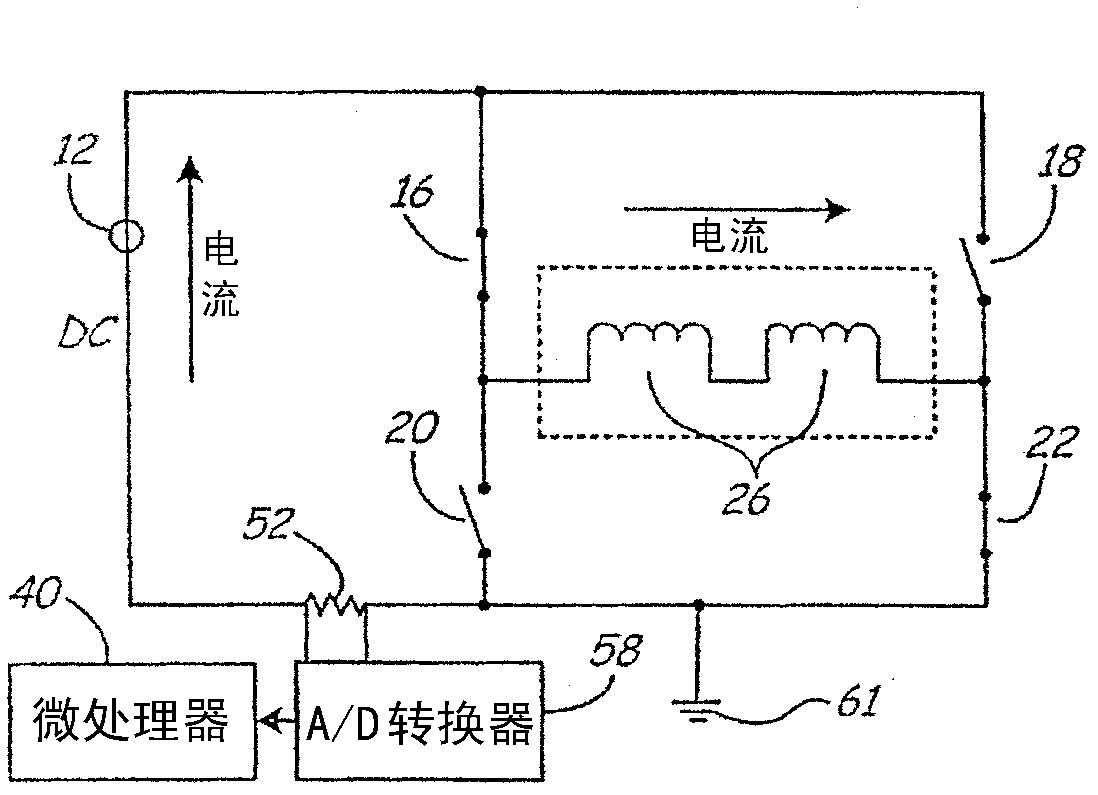

[0013] figure 2 The driver circuit 10 in the transmitter 9 is shown. The H-bridge flow tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com