A pretreatment can packaging device for removing iron cans from waste cans

A technology for discarded pop-top cans and pop-top cans, which is applied in the directions of manufacturing tools, solid separation, chemical instruments and methods, etc., can solve the problems of downgraded use of discarded pop-top cans, difficult to achieve classification effect, and lack of full automation, and achieves the effect of saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

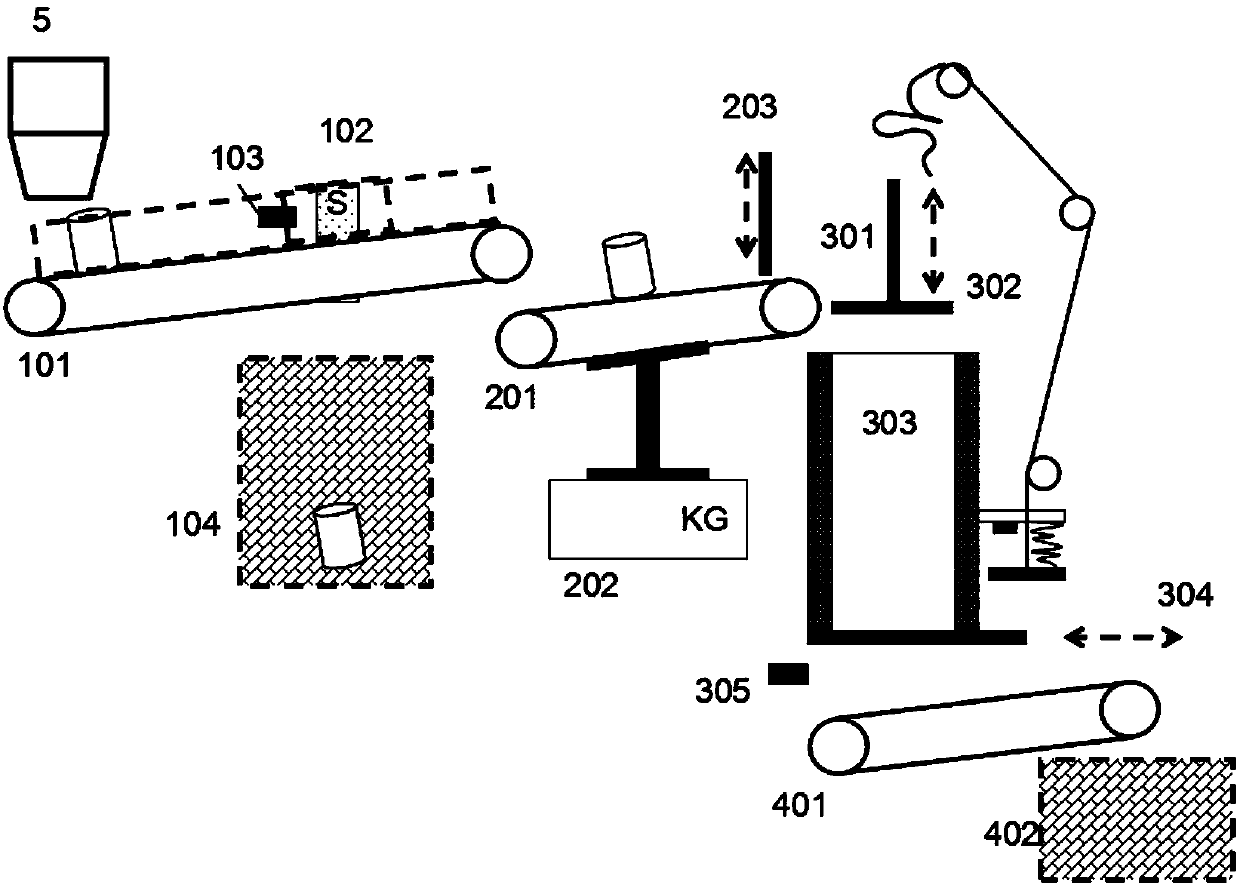

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

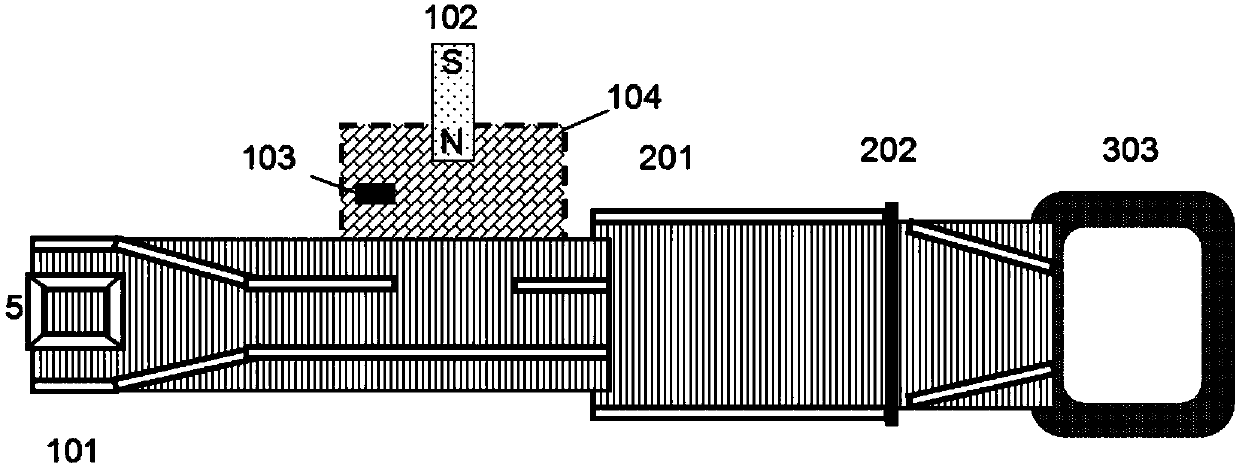

[0029] A can packaging device for removing iron cans from discarded pop cans, which is characterized in that it includes a feeding system, a feeding system, a can packaging system, a feeding system, a pretreatment funnel, and a control host.

[0030] Further, the feeding system includes: a feeding conveyor belt 101, a powerful electromagnet 102, a first optical detection device 103, and a waste recycling bin 104; both sides of the feeding conveyor belt have a first side baffle and a second side baffle, and the feeding Conveyor belt width 30cm, the distance between the first side baffle and the second side baffle at the starting end of the feeding conveyor belt is 30cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com