Oil channel structure of cold bending machine for forming three-dimensional curved surface plate material and method for pressing plate material

A three-dimensional curved surface, cold bending machine technology, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of unattainable, difficult to achieve high-precision pressing, unqualified products, etc., and achieve the effect of improving the product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

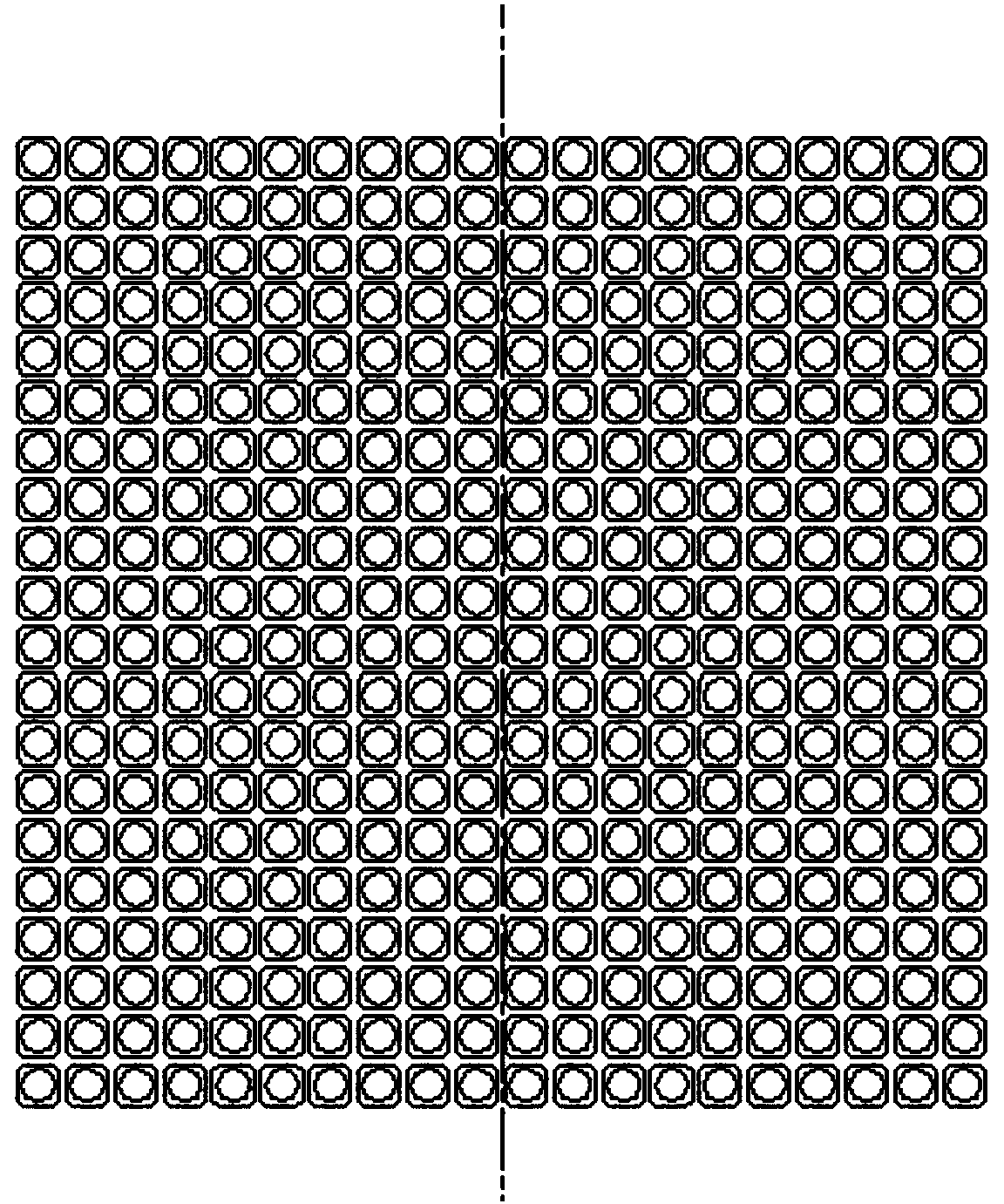

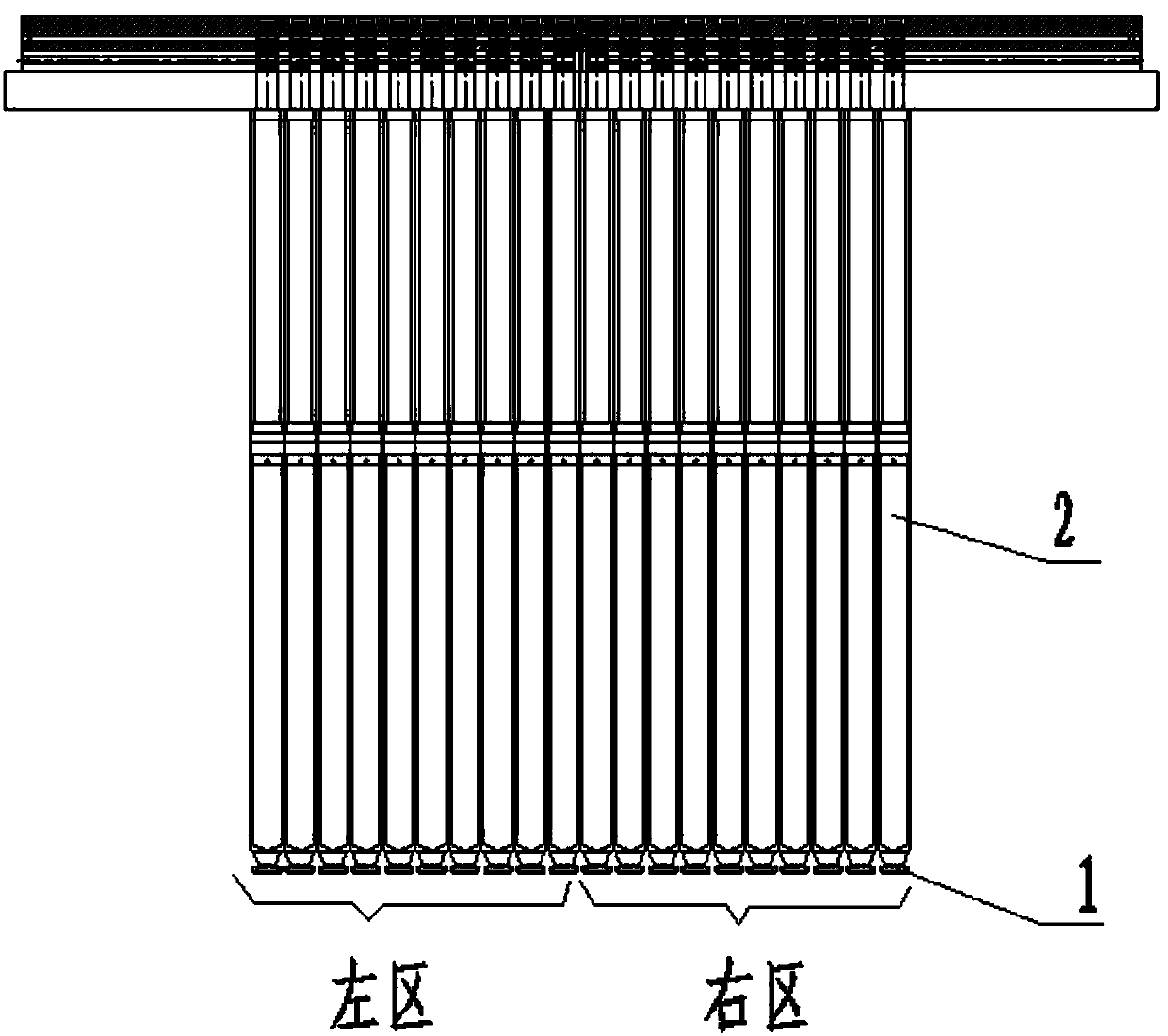

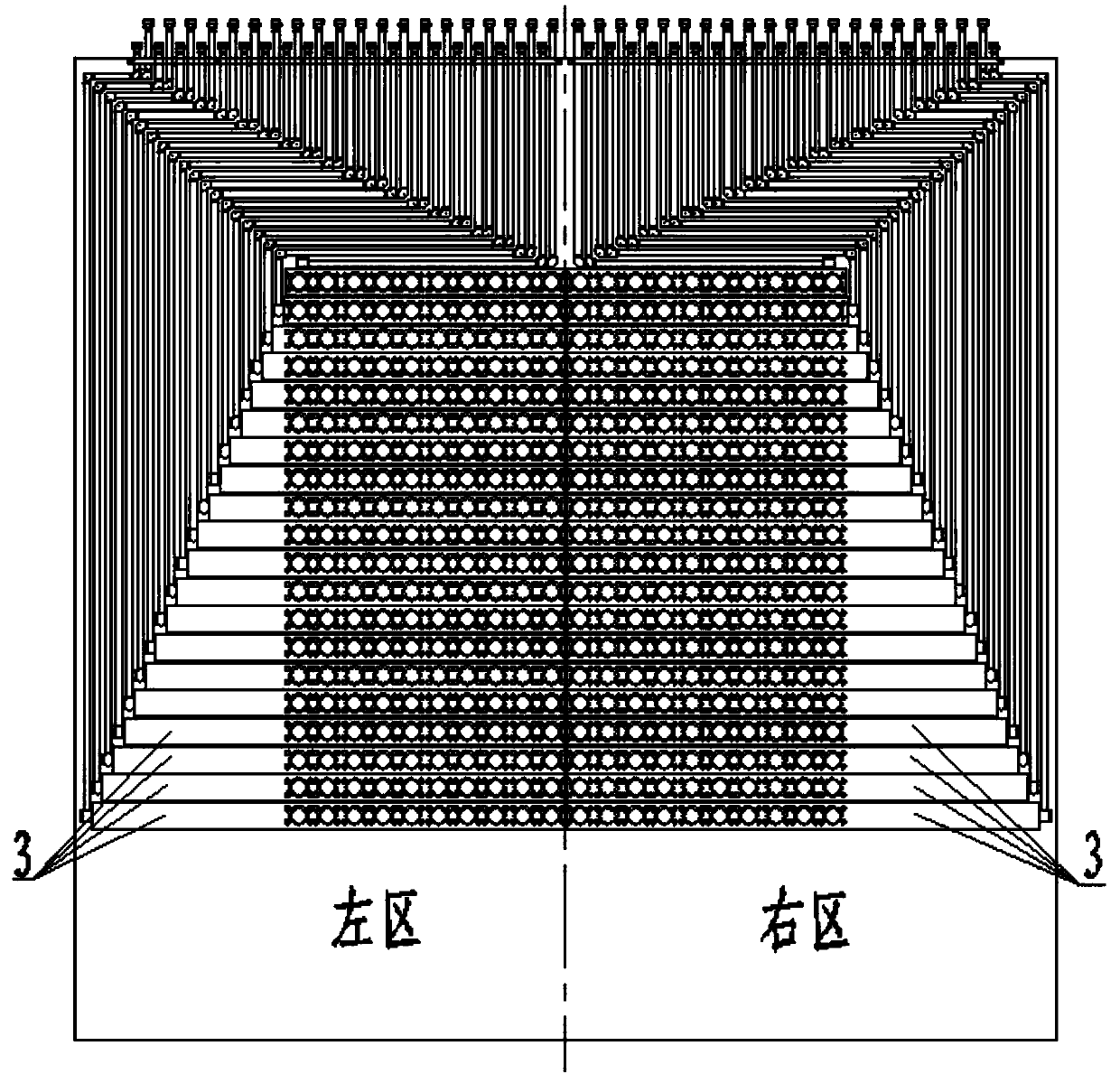

[0015] as attached Figure 1-Figure 3 As shown, an oil channel structure for forming a three-dimensional curved plate cold bender includes a hydraulic cylinder 2 connected to the pressure head 1 of the upper die / lower die of the cold bender, and the upper die / lower die of the cold bender has M×N indenters 1 arranged in a matrix, corresponding to the arrangement of the indenters of the upper mold / lower mold of the cold bending machine, divide the indenters 1 into left and right zones from the center of the mold, and the indenters in each zone 1 An independent oil channel 3 is respectively arranged in accordance with a row or a column of pressure heads, and each oil channel 3 communicates with the hydraulic cylinder 2 correspondingly connected to each pressure head 1 in the corresponding row or column in the area, and The oil passage 3 in the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com