Blocking method of outer wall hole and blocking filling hopper

A technology for exterior walls and holes, which is applied in building maintenance, construction, building construction, etc., can solve the problems of poor filling, troublesome operation, easy to open, etc., and achieve the improvement of impermeability, simple method and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

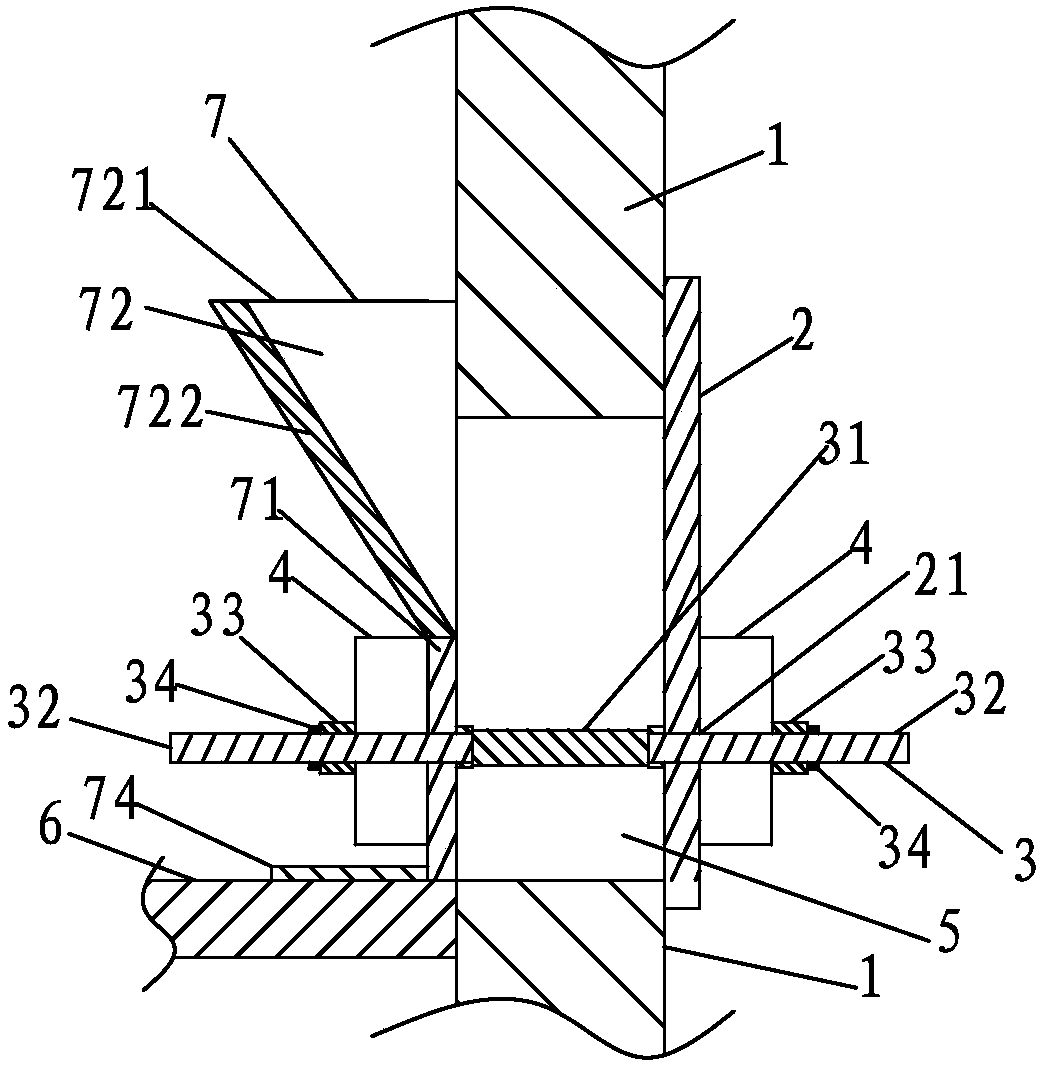

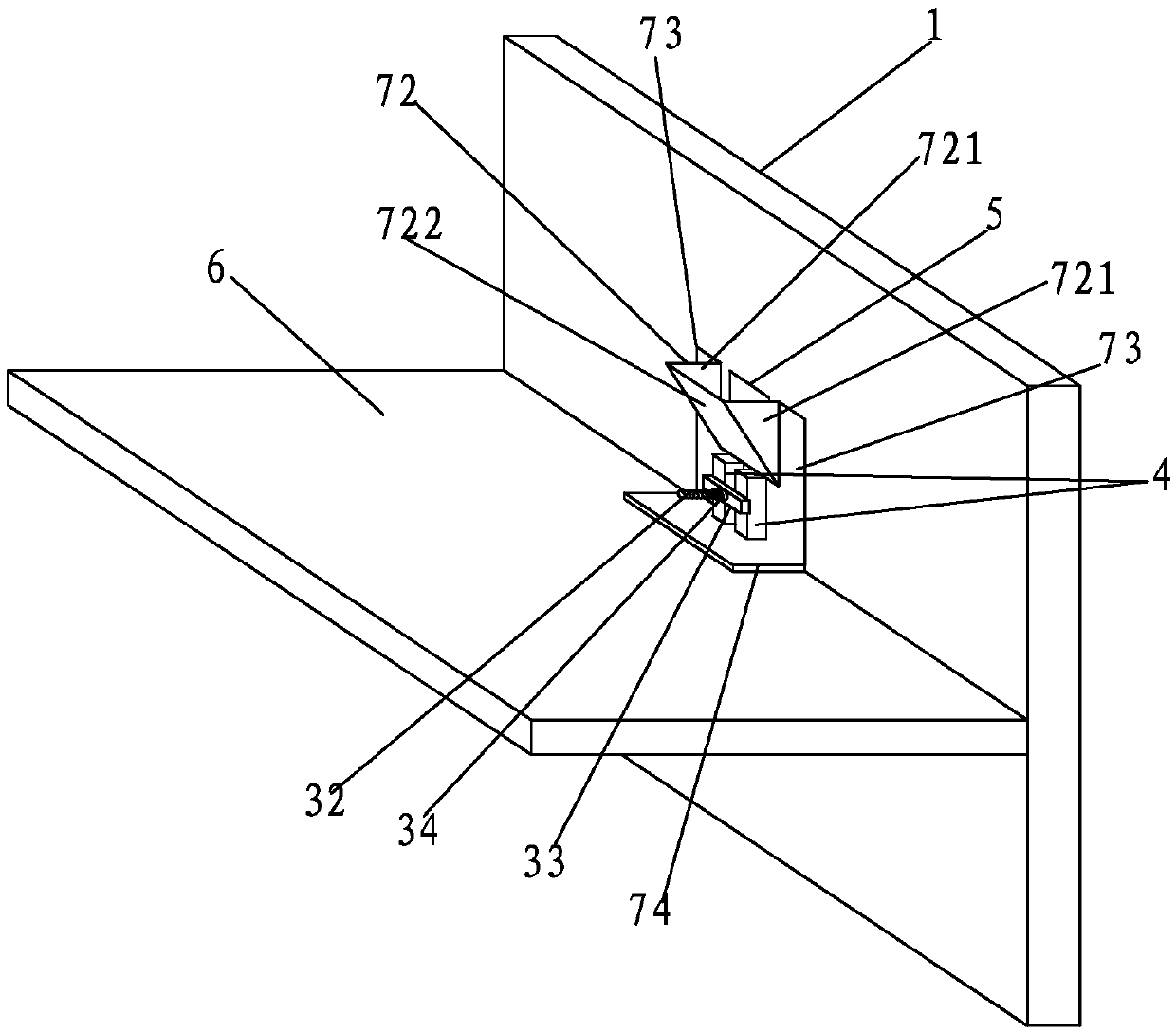

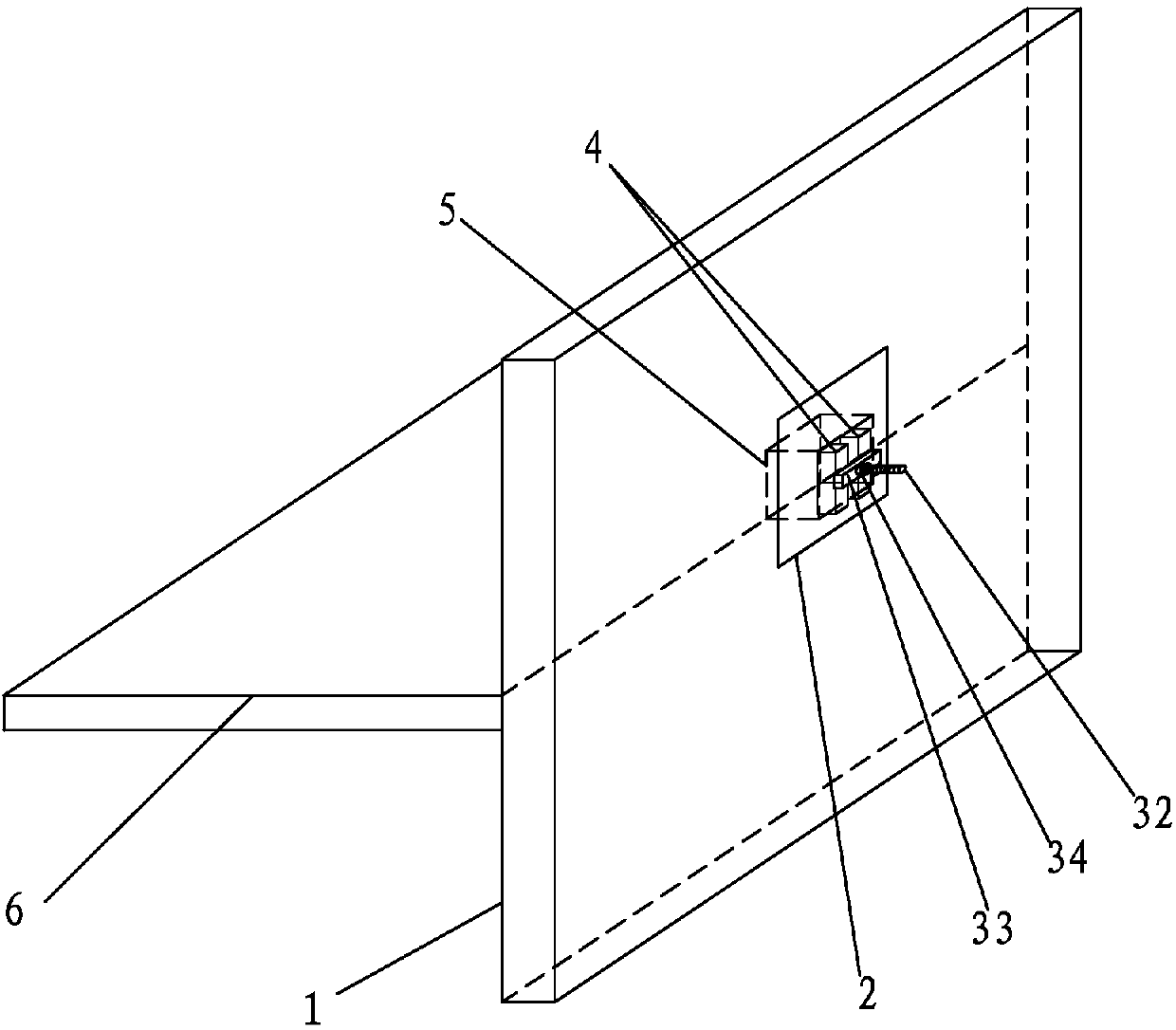

[0025] see Figure 1-4 Shown, a kind of plugging method of exterior wall hole, comprises the following steps:

[0026] Step S1, chiseling and rinsing the inner wall of the outer wall hole 5;

[0027] Step S2, making a filling hopper 7 according to the size of the outer wall hole 5, the filling hopper 7 includes a baffle 71 and a filling tank 72, the filling tank 72 has a bottom plate 722 and two side plates 721, two The side plates 721 are erected on the left and right sides of the bottom plate 722; the baffle plate 71 is connected to the bottom edge of the bottom plate 722, and the baffle plate 71 is also provided with a through hole 711,

[0028] Making the plugging part 2 used for plugging the hole 5 on the outer side of the outer wall 1, the plugging part 2 is provided with a perforation hole 21;

[0029] Step S3, select a three-section water-stop double-pull bolt 3, the three-section water-stop double-pull bolt 3 includes a connecting rod 31, two screw rods 32, two clip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com