Sealed electric elements

An electrical component, sealing technology, applied in the direction of electrical components, resistor components, circuits, etc., can solve the problem that the sealing resin cannot be fully bonded to the inner peripheral surface of the box, the sealing resin cannot be bonded, and the airtightness is damaged. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

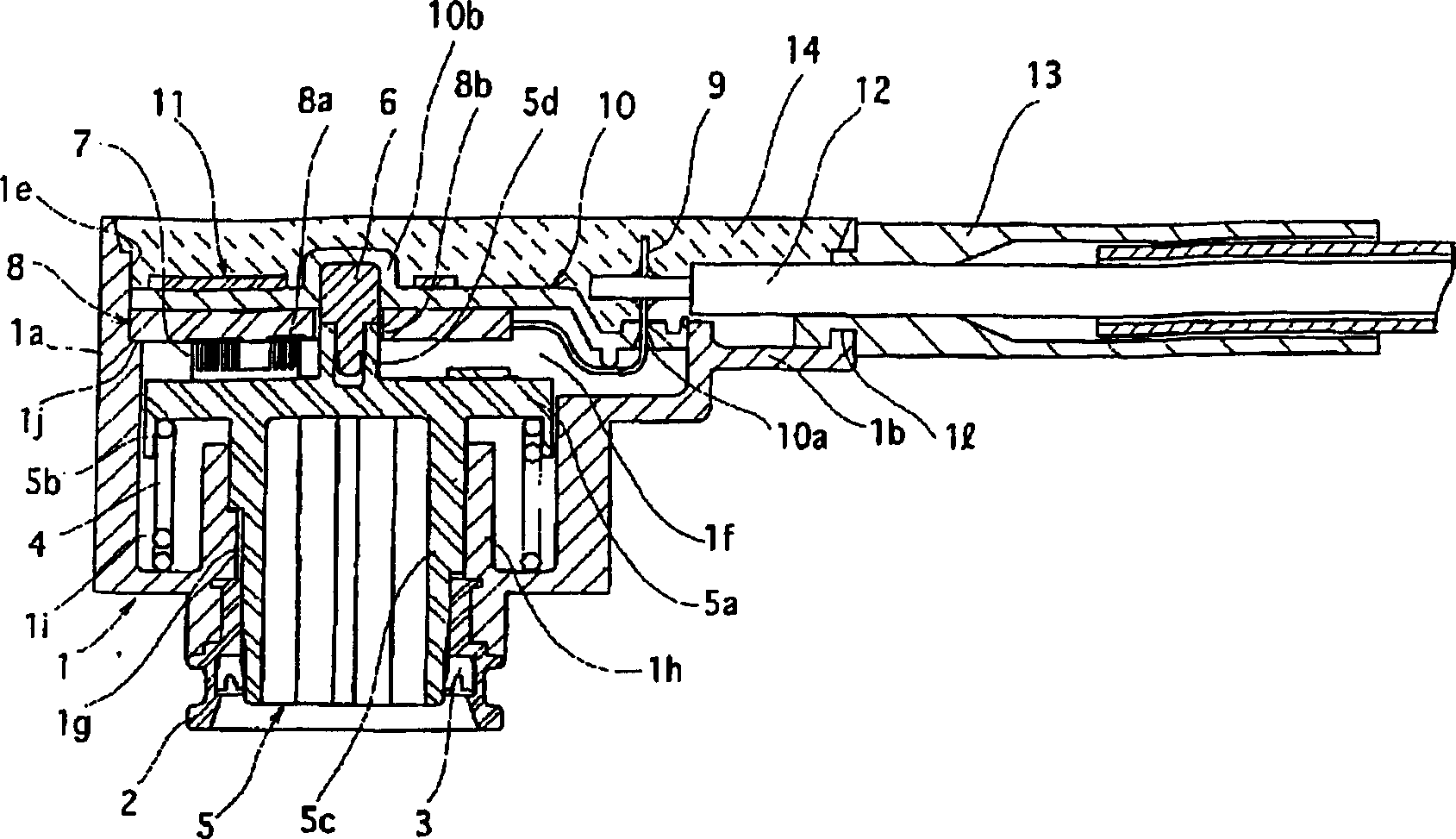

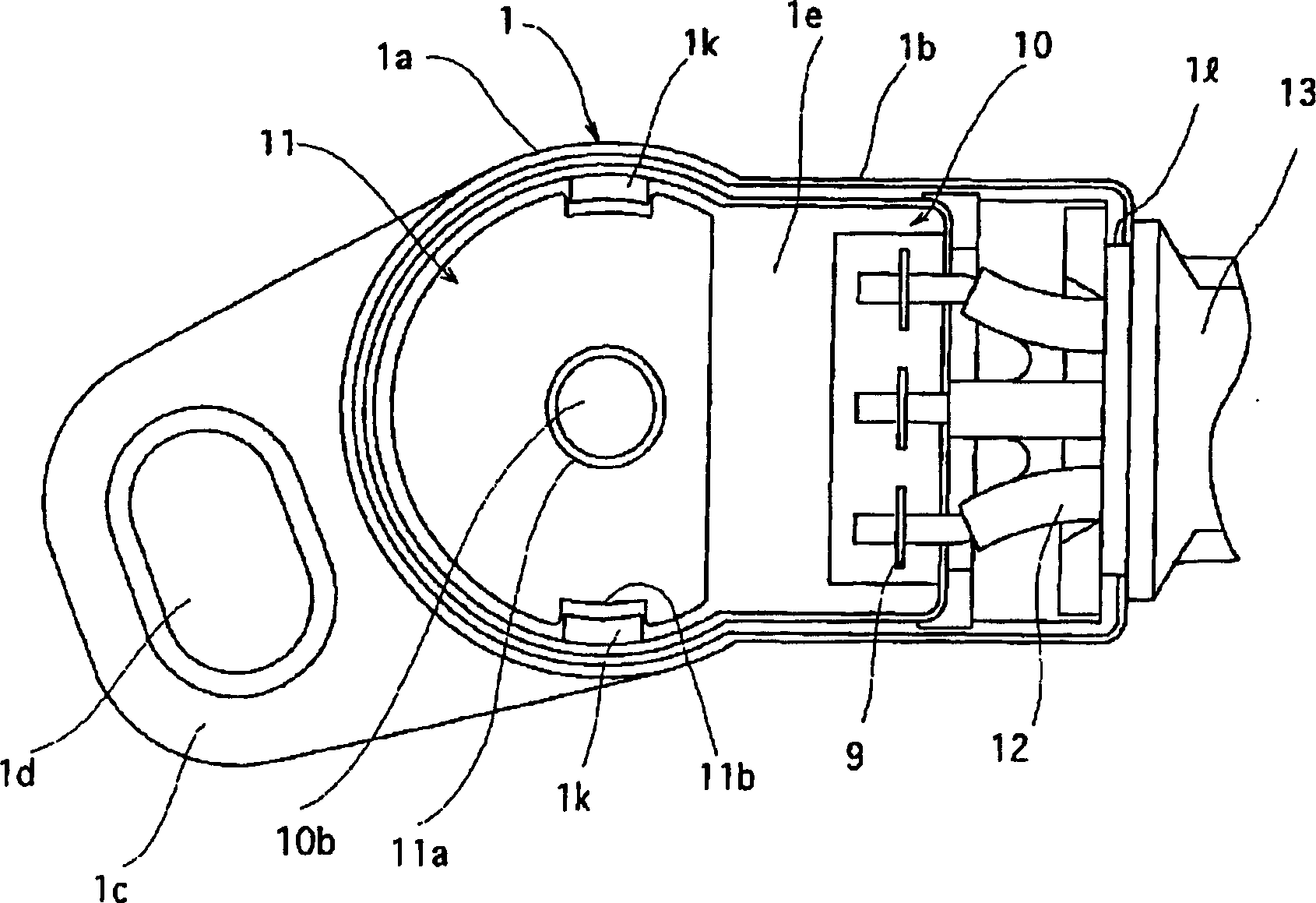

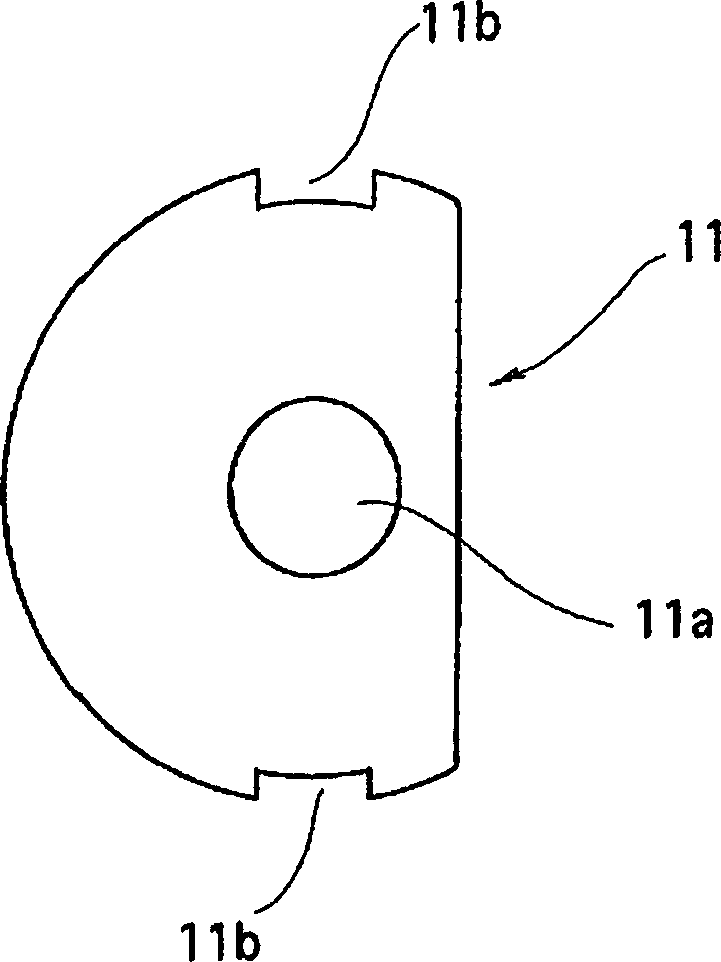

[0018] Figure 1 to Figure 3 An example of the present invention is shown. figure 1 is a cross-sectional view of the sealed electrical component of the present invention, figure 2 is a top view of a sealed electrical component, image 3 It is a plan view of the separator of the sealed electrical part.

[0019] In the figure, the box body 1 is formed of an insulating material such as synthetic resin into a box shape with an open top, and is formed by a substantially cylindrical base 1a and a substantially rectangular platform 1b protruding from one side of the base 1a. Moreover, on the other side surface of the base part 1a, the mounting plate 1c of a substantially table shape is extended toward the direction opposite to the table part 1b. An elliptical screw hole 1d is provided in the mounting plate 1c, and external screws are inserted into the screw hole to be mounted on a chassis or the like. In addition, a continuous opening 1e is provided on the top side of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com