Prefabricated segment assembling concrete bridge pier and assembling method

A technology of prefabricated sections and concrete, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc. It can solve the problems of insufficient shear resistance and stability, low bearing capacity, etc., so as not to slip easily and improve the shear bearing capacity force, the effect of large shear capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

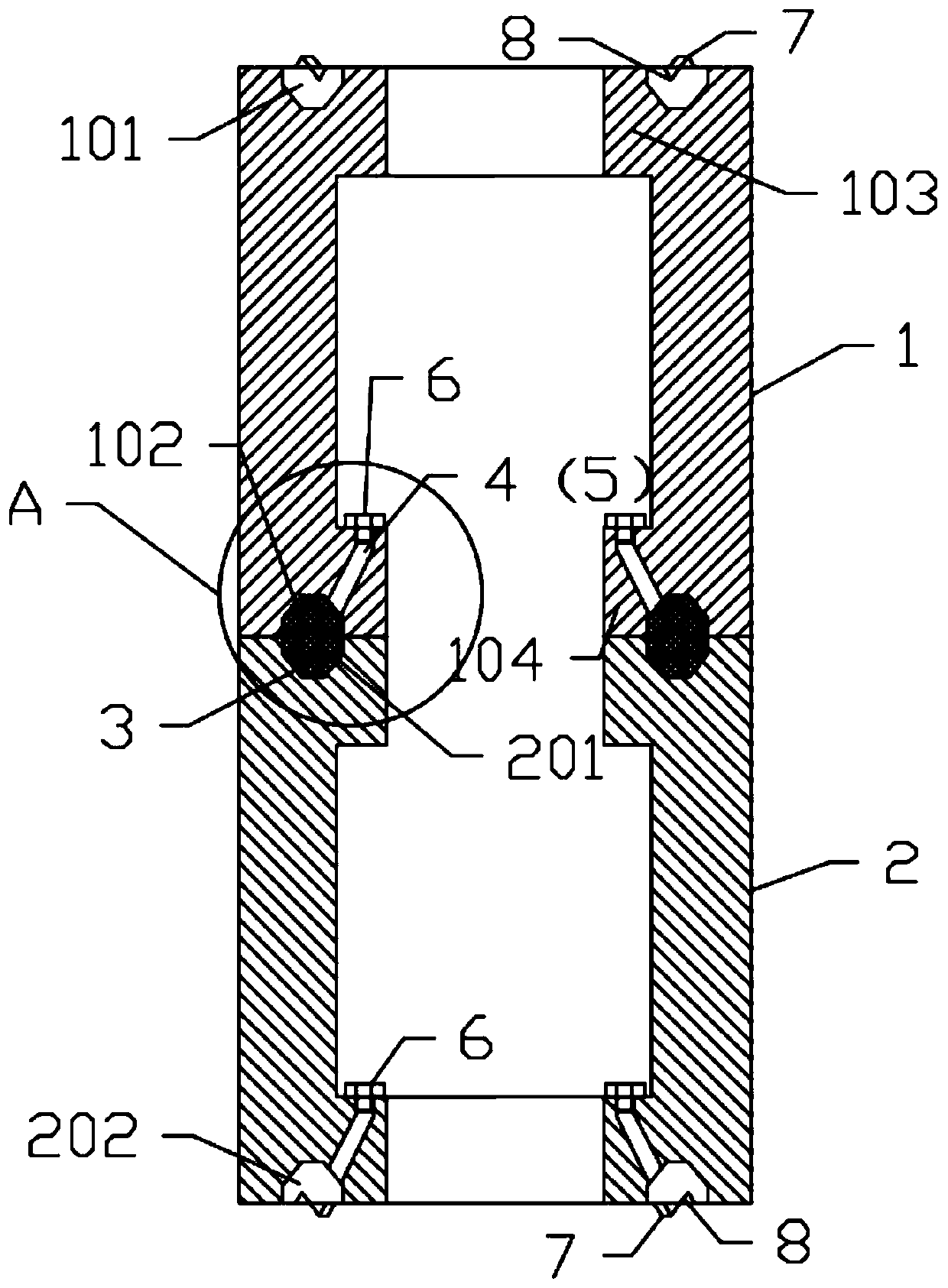

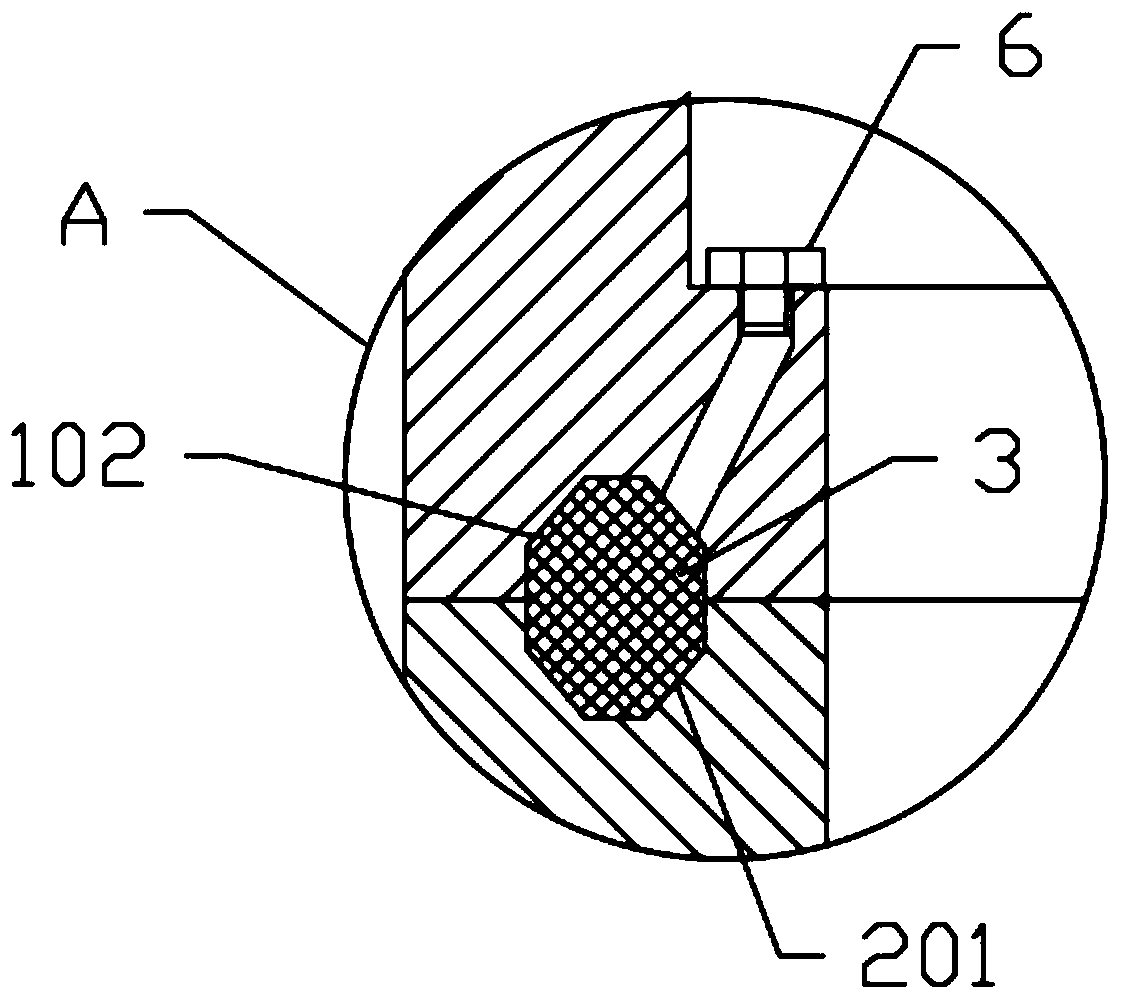

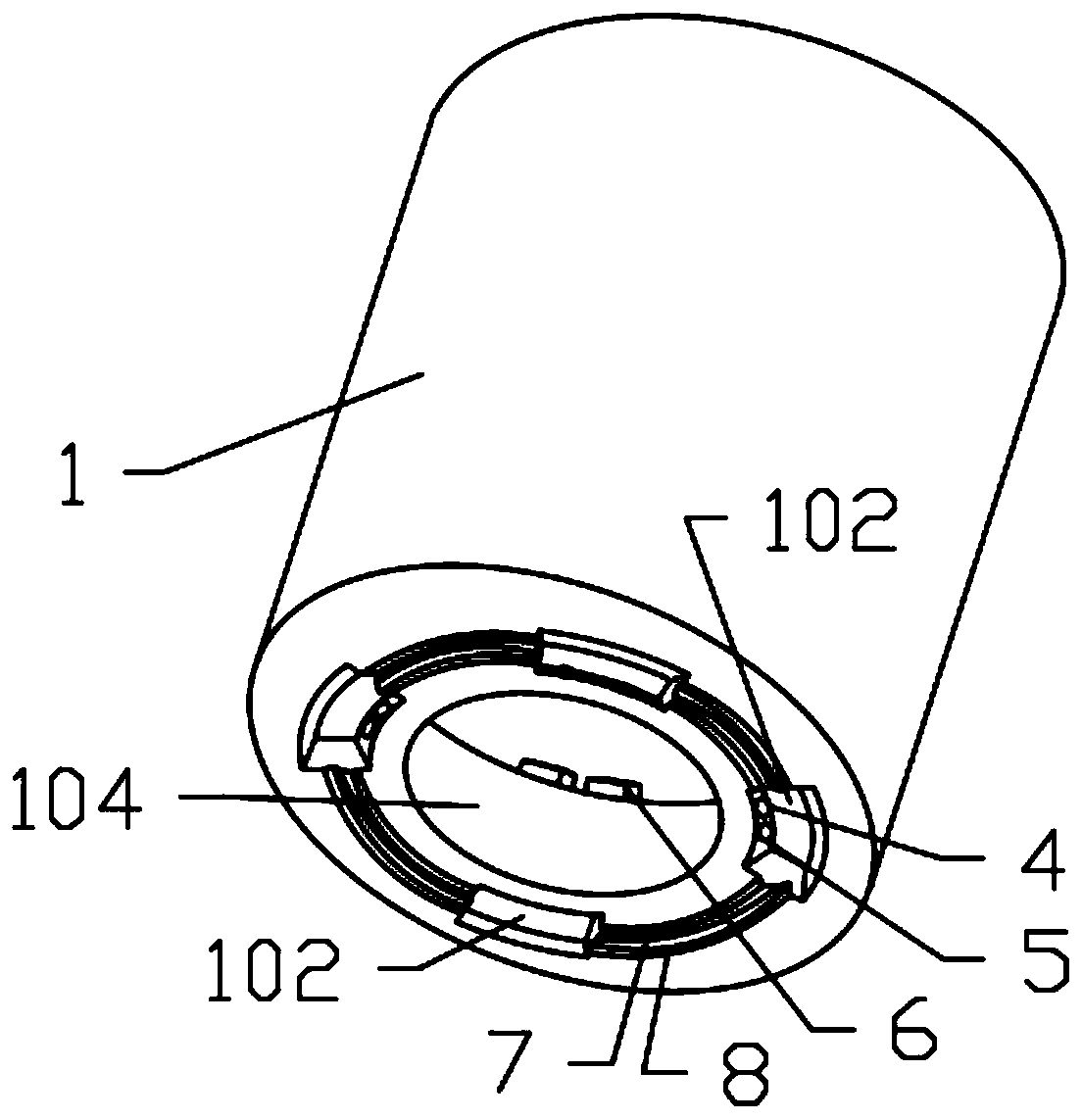

[0024] Embodiment 1, the prefabricated section-assembled concrete pier of the present invention includes a pier body assembled from several pier prefabricated sections from bottom to top. This embodiment takes two pier prefabricated sections as an example, including the upper pier prefabricated section 1 and the lower pier pier The prefabricated section 2, the pier prefabricated section 1 and the lower pier prefabricated section 2 are all columnar structures, the connection of two adjacent pier prefabricated sections is provided with a shear key 3, and the upper end surface and the lower end surface of the upper pier prefabricated section 1 are provided with useful For installing the top installation groove 101 and the bottom installation groove 102 of the shear key, the upper end surface and the lower end surface of the lower pier prefabricated section 2 are provided with the top installation groove 201 and the bottom installation groove 202 for installing the shear key. The u...

Embodiment 2

[0032] Embodiment 2, the difference between this embodiment and Embodiment 1 is that the groove 8 in this embodiment is continuous and plays the same role, but forms a ring, so that less impurities or dust can enter the accommodating chamber Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com