Wig production process

A production process and wig technology, applied in the field of wig production technology, can solve the problems of low fidelity, large rhombus, troublesome process, etc., and achieve the effects of good air permeability, high fidelity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

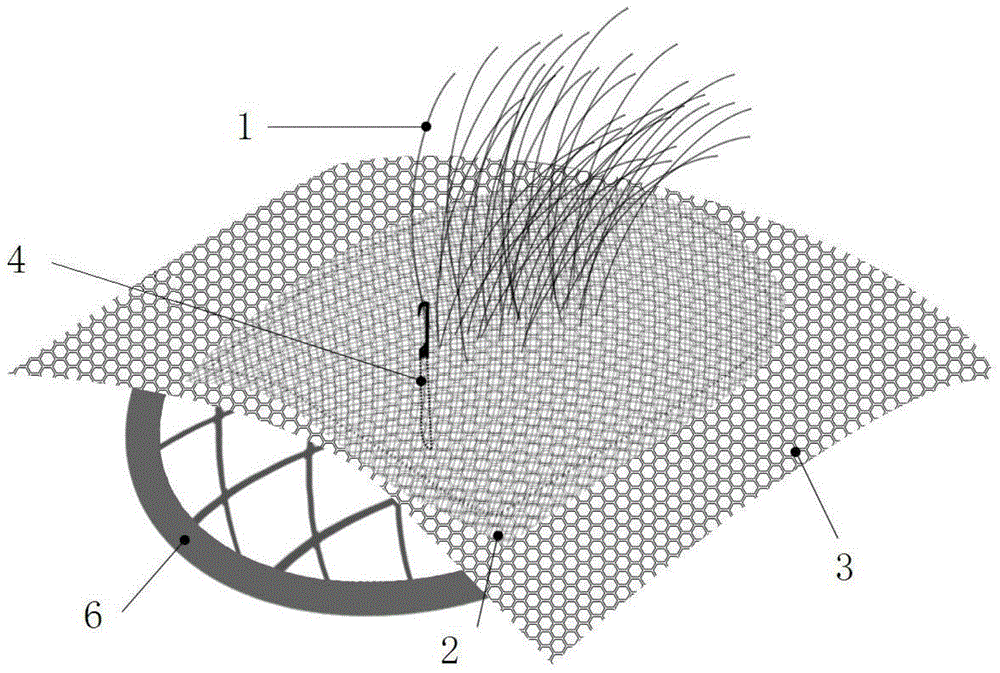

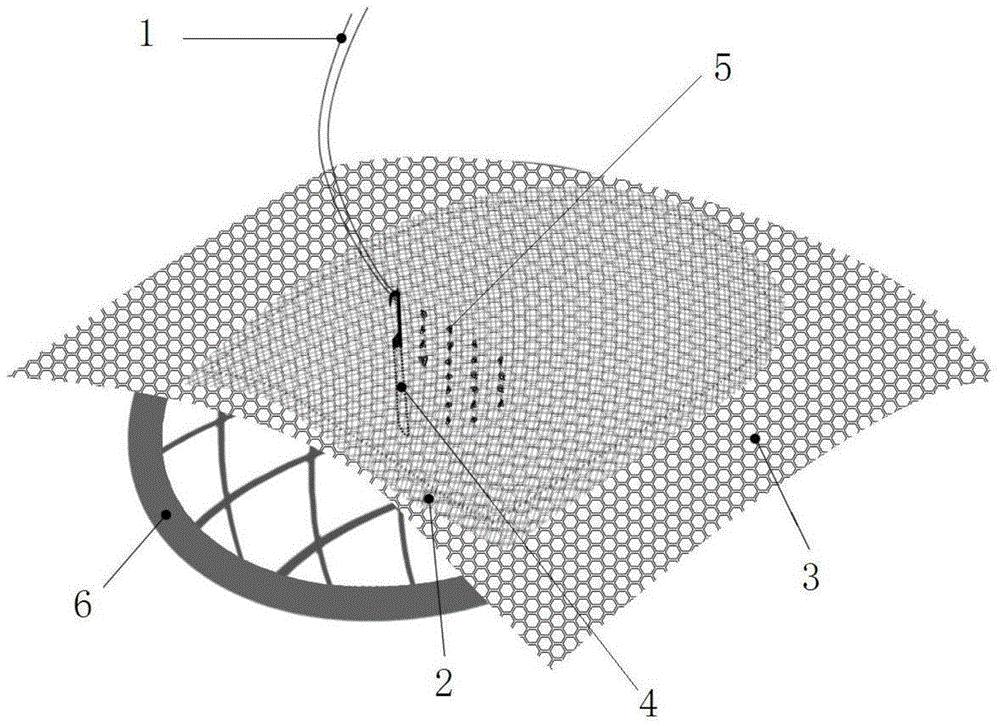

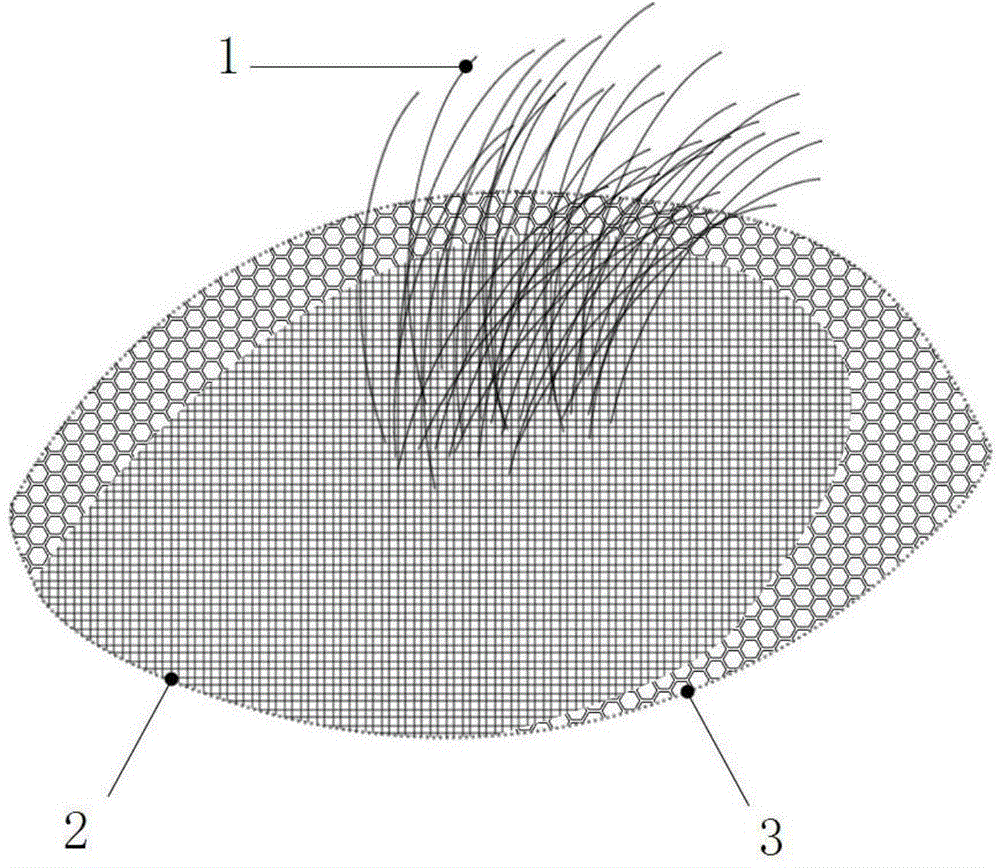

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] to combine Figure 1-5 Describe this embodiment, a kind of wig production process, fix the surface hair net 2 to the bottom hair net 3 to make the wig base, ensure that the surface hair net 2 and the bottom hair net 3 have the same curvature, and fix the wig base to a similar shape. On the wig mold 6 of the radian of the human head, plan the hair flow direction on the wig base; use the wig hair 1 to utilize the mesh gap of the surface hairnet 2, and use the single buckle method to hook the wig hair 1 with hook 4 Knit on the bottom hair net 3, the wig hair 1 is exposed below the bottom hair net 3, and the hair knot 5 is crocheted on the bottom hair net 3 and is positioned at the back side of the bottom hair net 3; The wig hair 1 below the bottom hair net 3 passes through the bottom hair net 3 and the surface hair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com