Door anti-slamming device

一种设备、门防的技术,应用在门防猛关设备领域,能够解决门防猛关设备不好用、门防猛关设备不能容易地调节需求或改变状态等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

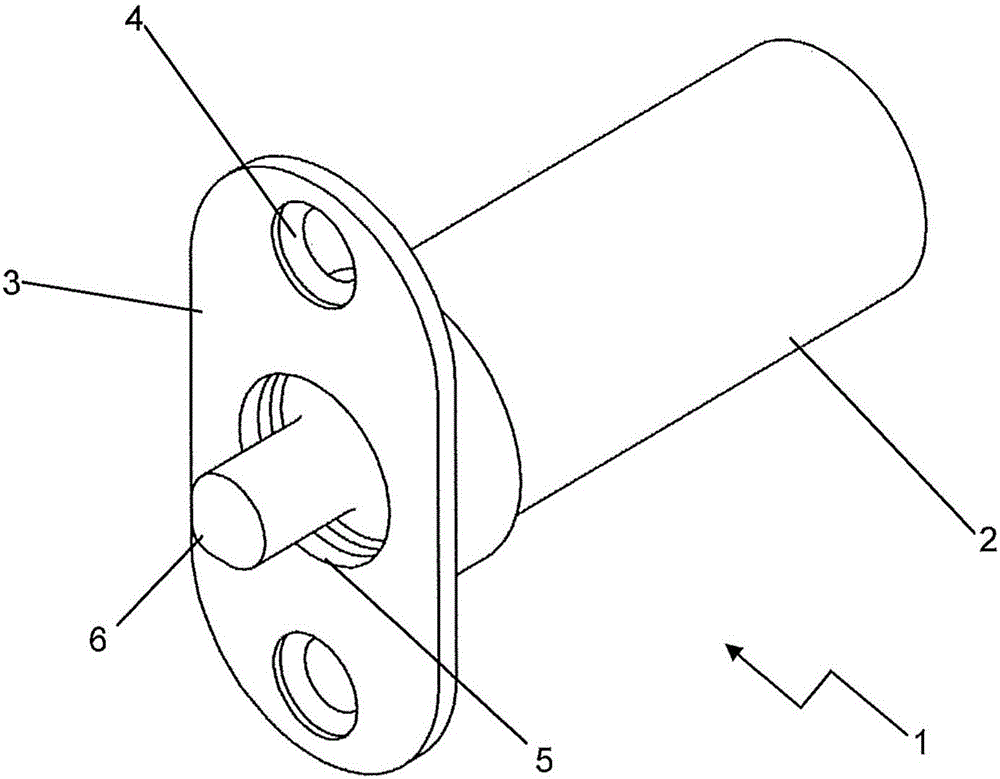

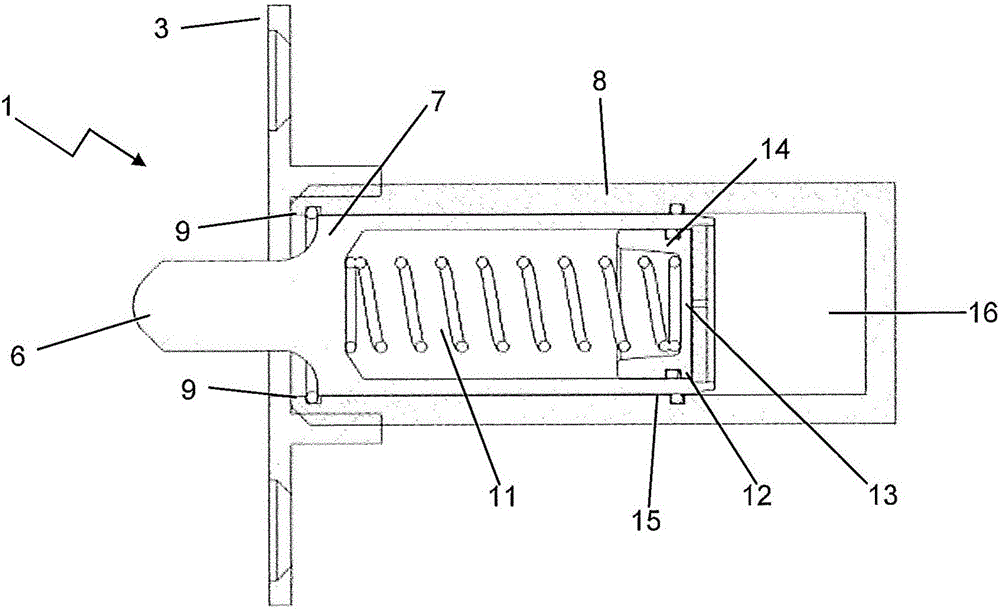

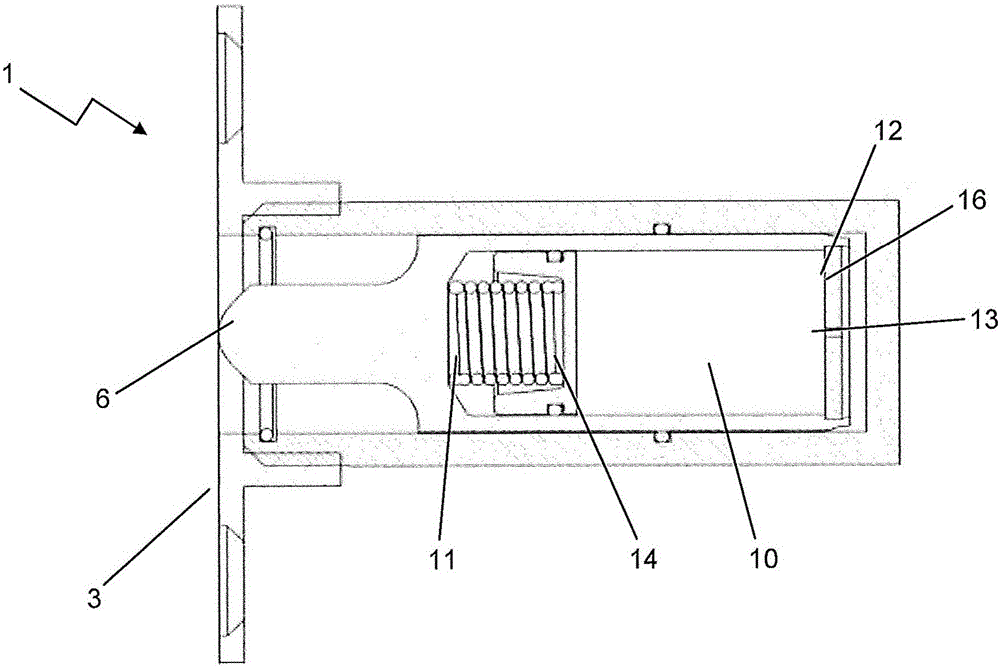

[0205] Figure 2A and 2B An apparatus according to Embodiment 1 of the present invention is shown.

[0206] The device 1 comprises a plunger 7 configured to slide in a chamber 8, also cylindrical. The inlet 5 includes a stop 9 . The head end 6 of the plunger 7 protrudes 18 mm beyond the inlet 5 .

[0207] The plunger 7 comprises a second cavity 10 and biasing means configured as a spring loaded coil 11 . The second cavity 10 is formed by the inner wall of the plunger 7 , the spacer 12 comprising the hole 13 and the movable wall 14 engaging the spring-loaded coil 11 . The plunger 7 and the walls of the chamber 8 comprise O-rings 15 to effectively seal the different parts of the device 1 .

[0208] like Figure 2A As shown, chamber 8 includes a first cavity 16 that is enlarged when the device is in the deployed configuration. In this configuration, the second cavity 10 is contracted. transfer to Figure 2B , the first cavity 16 contracts and the second cavity 10 expands a...

Embodiment 2

[0212] Figure 5A and 5B Each shows the device according to Embodiment 2 of the present invention in an expanded configuration and a compressed configuration.

[0213] In Embodiment 2, through the plunger 7 configured as a concentrated cylinder, the inner wall of the chamber 8 , the spacer 12 containing the hole 13 , and The interaction relationship between the movable walls 14 is used to form the second cavity 10 .

[0214] The biasing means 11 is located in the first cavity 16 and is biased towards the enlarged first cavity 16 . The first cavity 16 is located in the peripheral portion of the chamber 8 remote from the inlet 5 .

[0215] As plunger 7 is pressed into chamber 8, material (not shown) passes through bore 13 and forces moveable wall 14 back to expand the size of second chamber 10 to accommodate movement from first chamber 16. placed materials.

Embodiment 3

[0217] Figure 6A and 6B Each shows a device according to embodiment 3 of the invention in an expanded configuration and a compressed configuration.

[0218] In embodiment 3, the spacer 12 is a fixed wall integrated into the chamber 8 , wherein the spacer 12 comprises a hole 13 comprising a nozzle 20 .

[0219] The second cavity 10 is located on the opposite side of the partition 12 and away from the inlet 5 . A second cavity 10 is delimited by the inner wall of the chamber 8 , the spacer 12 and the movable wall 14 biased towards the spacer 12 by the spring-loaded coil 11 .

[0220] The first cavity 16 is located on the side of the spacer 12 opposite the second cavity 10 and close to the inlet 5 and is defined by the inner wall of the chamber 8 , the spacer 12 of the receiving hole 13 and the front surface 21 of the plunger 7 .

[0221] The plunger 7 is a solid cylindrical member forced into the first cavity 16 .

[0222] It should be understood that aspects of any of Emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com