Fixing structure and pre-embedment construction method for pre-embedded channel for duct piece in subway shield zone

A fixed structure and pre-embedded channel technology, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as tight construction schedules, complicated electromechanical installation, and frequent cross operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

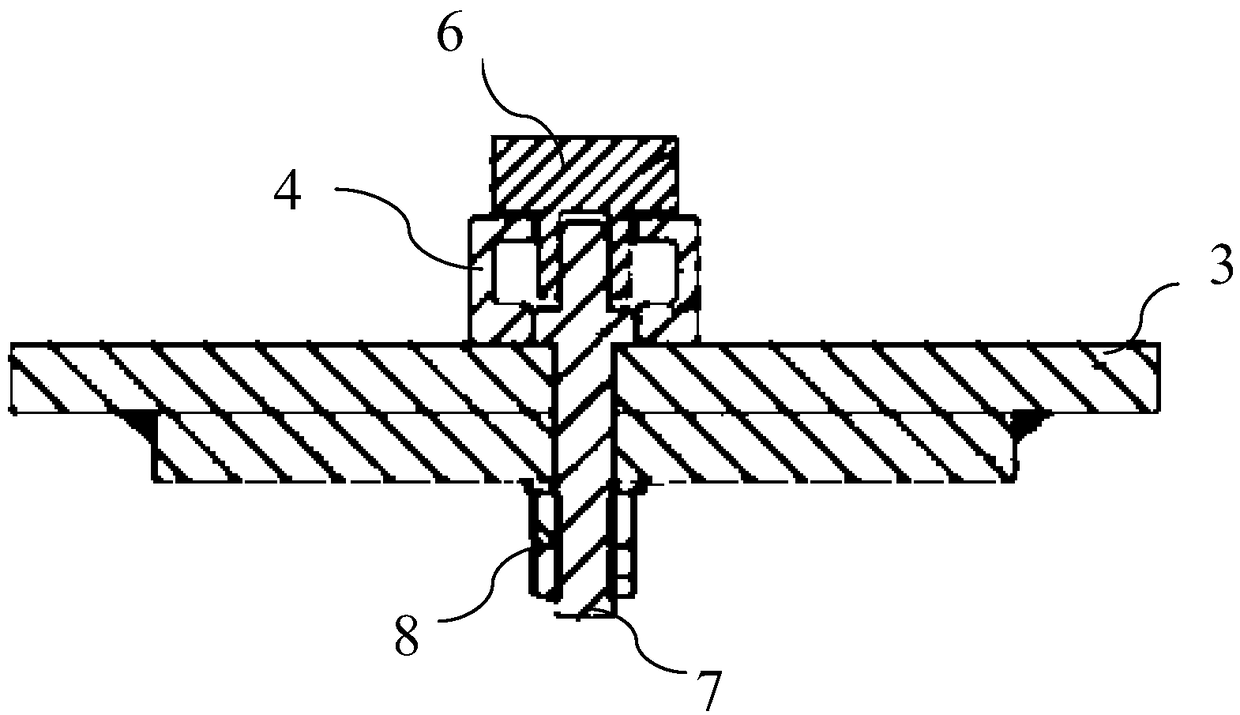

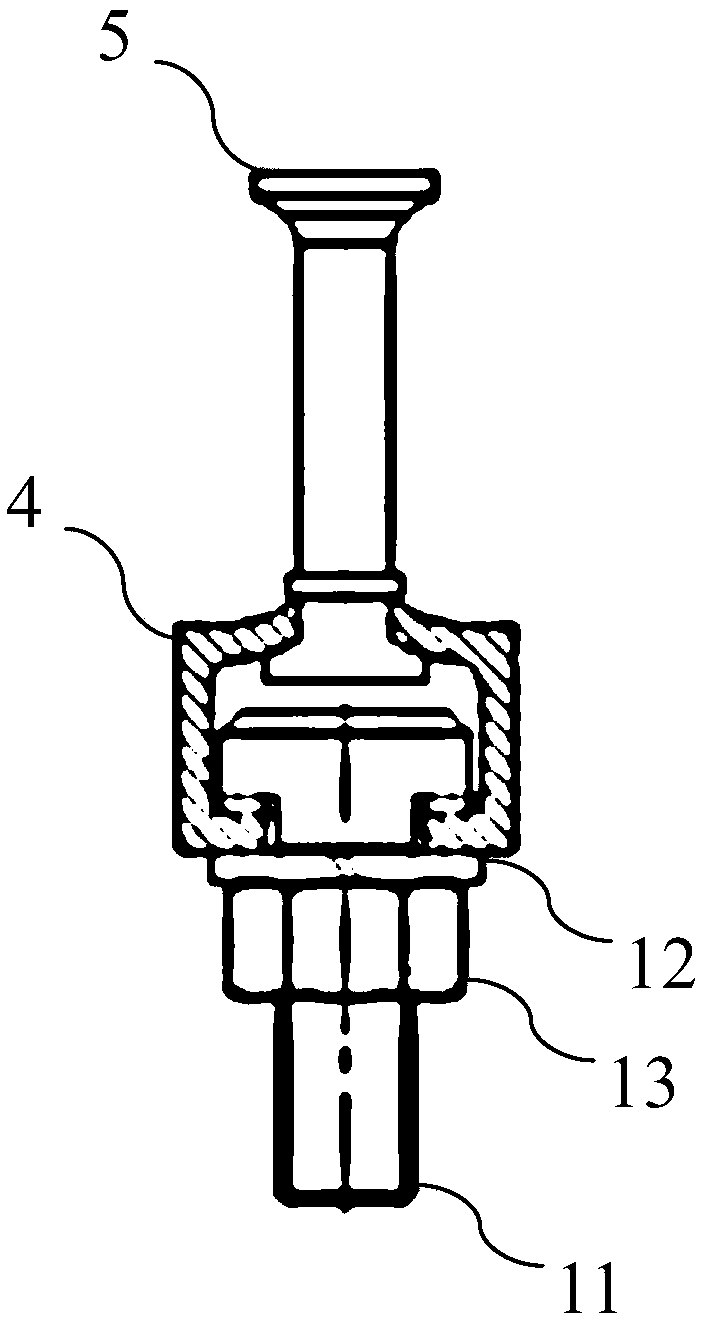

[0042] According to one embodiment of the present invention, the fixing structure 2 further includes a lock nut washer, and the positioning nut 6 has a large end with an outer diameter larger than the inner diameter of the installation hole and a small end with an outer diameter equal to the inner diameter of the installation hole. end, the small end of the positioning nut 6 has a threaded cavity for screwing into the one end of the positioning screw 7, and the lock nut washer is used to be clamped between the large end of the positioning nut 6 and the Between the closed surfaces of the arc-shaped channel steel 4, to increase the frictional force between the large end of the positioning nut 6 and the closed surface of the arc-shaped channel steel 4, to prevent the arc-shaped channel steel 4 from The surface is scratched by the positioning nut 6 during fastening, which disperses the pressure of the positioning nut 6 on the sealing surface of the arc-shaped channel steel 4 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com