Inner-connection meshing type gear device

A gear device and gear technology, applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of inability to confirm the evaluation results of bearing monomers, inability to freely choose processing manufacturers, and affect product durability, etc., to achieve simple shape , Easy assembly and simplified internal accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

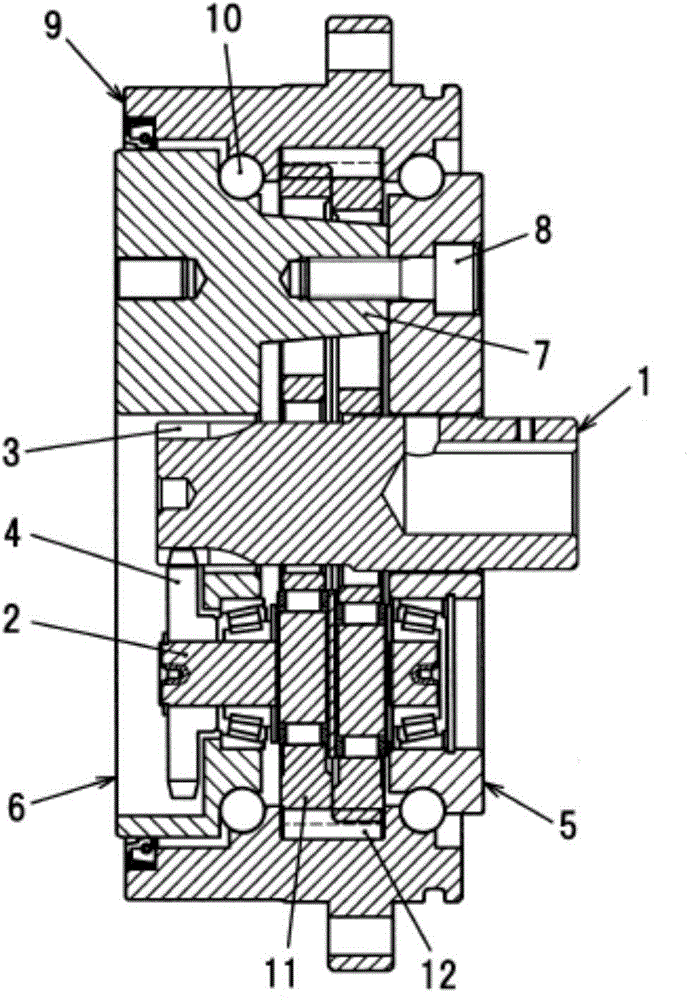

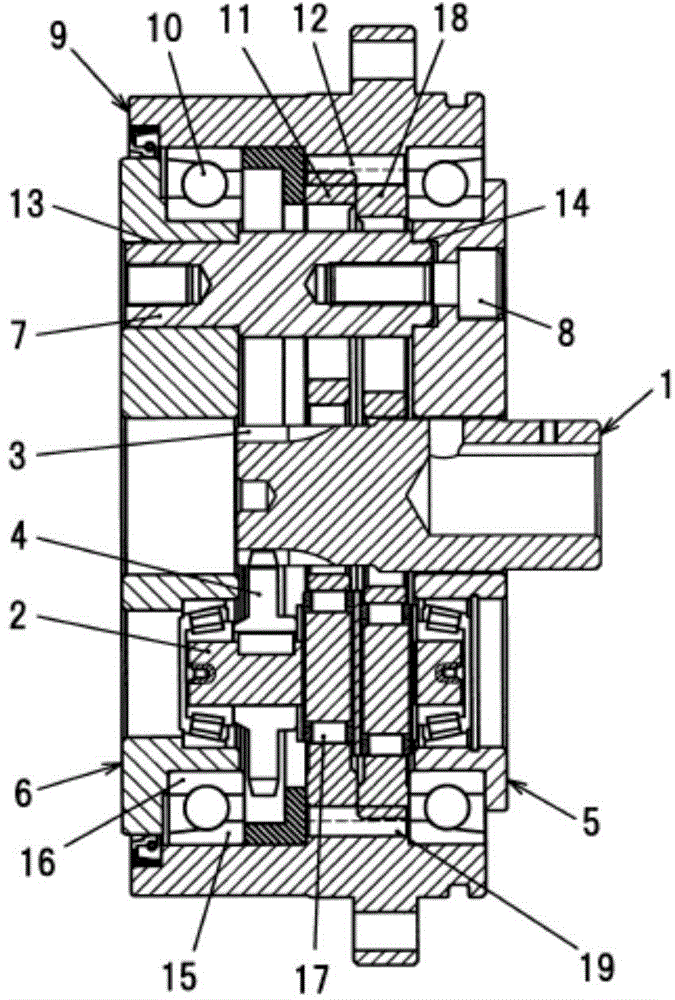

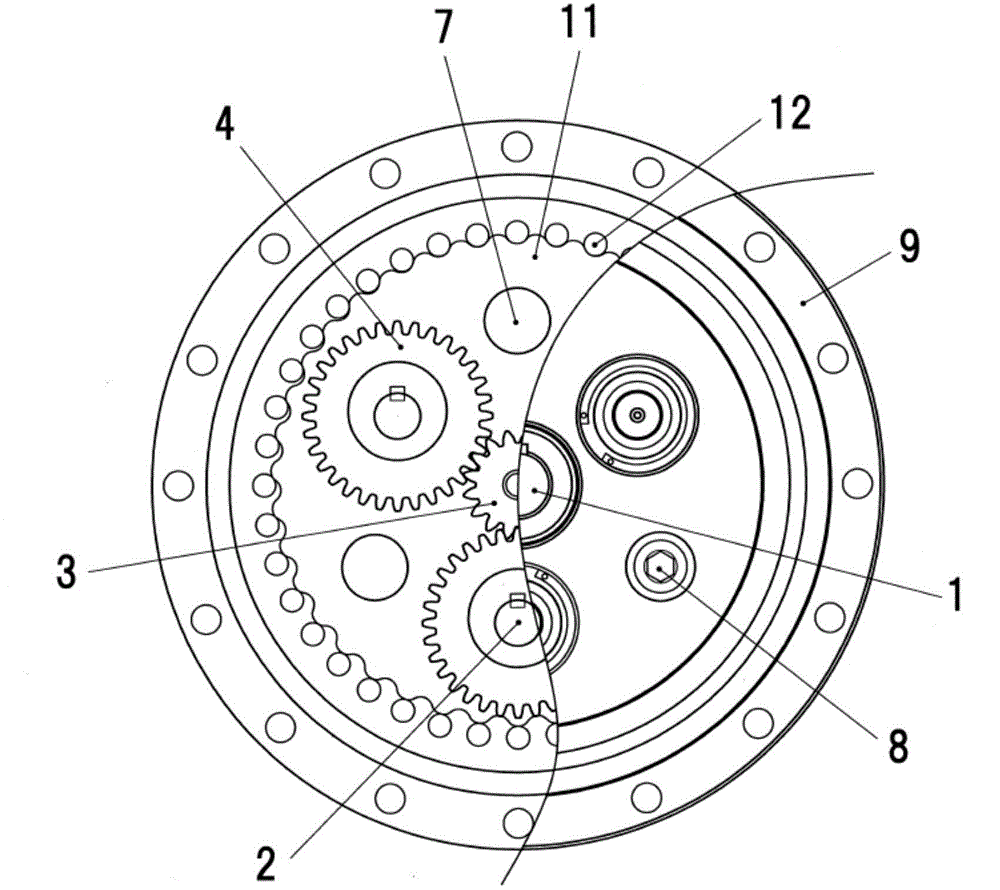

[0042] figure 1In Figure 4, 1-input shaft, 2-eccentric crankshaft, 3-sun gear, 4-transmission gear, 5-input side support body, 6-output side support body, 7-pillar, 8-bolt, 9-housing , 10-bearing, 11-external gear, 12-internal gear, 13-slot a, 14-slot b, 15-bearing outer ring, 16-bearing inner ring, 17-bearing b, 18-external gear b , 19-pin (internal teeth).

[0043] Such as figure 2 As shown, the present invention proposes an inscribed meshing gear device, which includes an external tooth gear with a cycloid tooth profile or a modified cycloid tooth profile, and an inner tooth with an arc tooth profile with more teeth than the external tooth gear The gear 12 has multiple eccentric crankshafts 2 supporting the swinging rotation of the external gear in order to enable the external gear to revolve in the internal gear 12, and further includes an input shaft 1, which is used as an input side power source, and a transmission gear 4, The transmission gear 4 is a spur gear, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com