Method for forming semiconductor packaging structure

A packaging structure and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of poor reliability of packaging structures and prone to failure, so as to improve stability and reliability, The effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

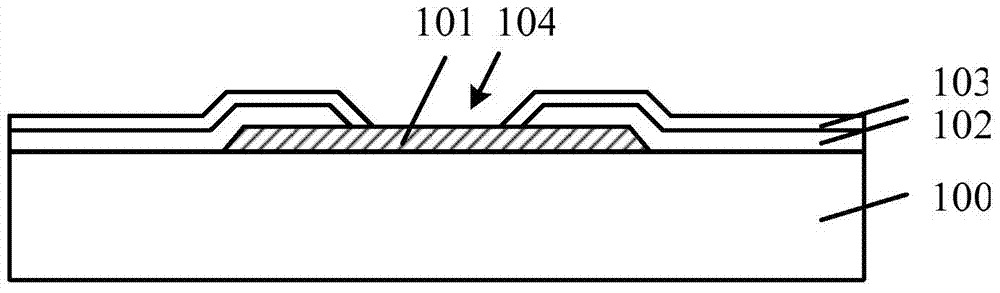

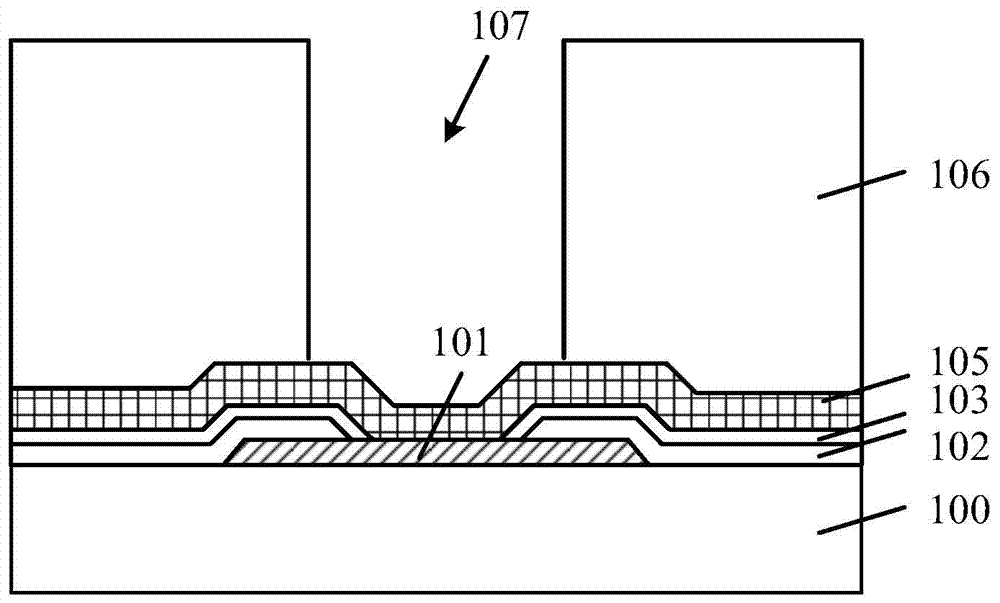

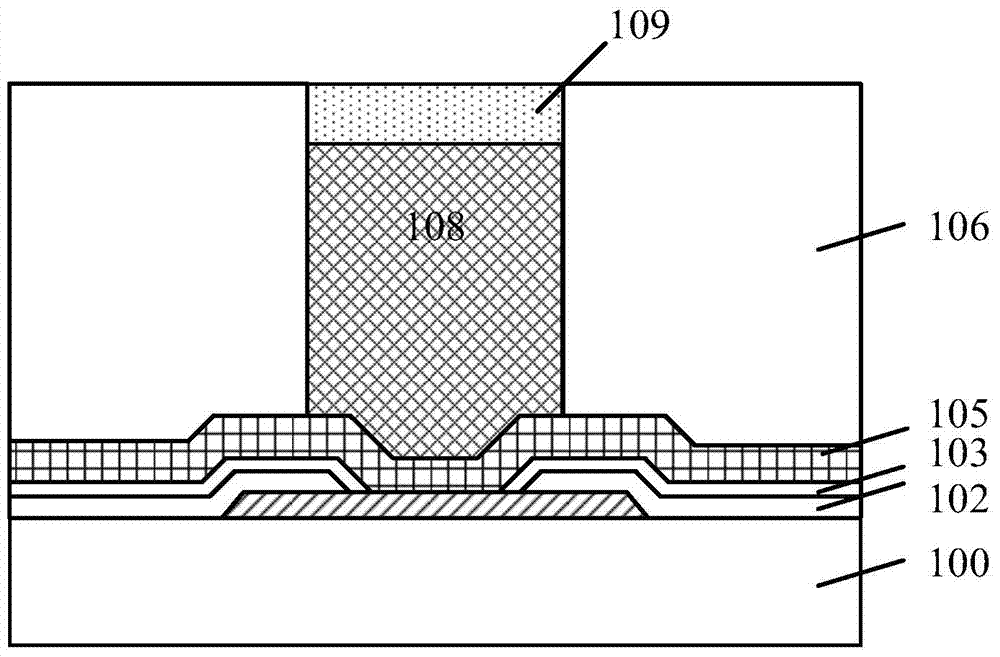

[0027] After research, it is found that the existing maskless wet etching method to remove the under-convex metal layer not covered by the metal pillars is prone to undercut defects. For details, please refer to image 3 and Figure 4 , when the metal post 108 is used as a mask to remove the metal layer 105 under the protrusion on the polymer layer 103 on both sides of the metal post 108 by wet etching, due to the isotropic property of wet etching, the removal of the metal under the protrusion layer 105 , it is easy to over-etch the part of the raised metal layer 105 under the metal pillar 108 , so that the remaining raised metal layer 105 under the metal pillar 108 is inwardly depressed to form an undercut defect 112 . The existence of the undercut defect 112 will make the bottom part of the metal pillar 108 suspended, so that the contact area between the metal pillar 108 and the metal layer 105 under the protrusion is reduced, and the adhesion between the metal pillar 108 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com