Filler-free synergistic compound fertilizer produced by urine syrup ammonia-acid method and production method thereof

A technology of uric acid and compound fertilizer, which is applied in fertilizer mixture, fertilization device, application and other directions, can solve the problems of inability to meet product quality and cost requirements, obvious influence of granulation and drying, weakening of crop production capacity, etc. Effects of crop stress resistance, improvement of agricultural product quality, and nutrient utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

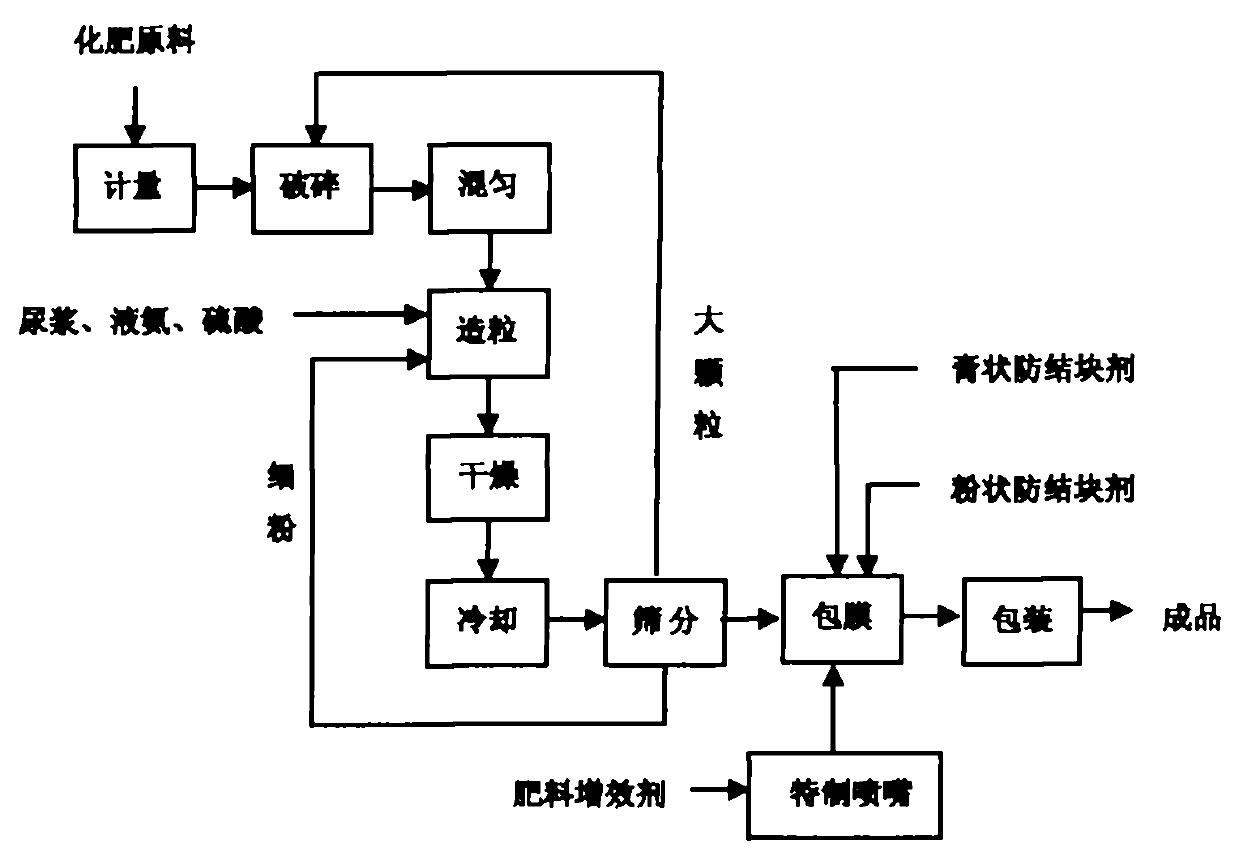

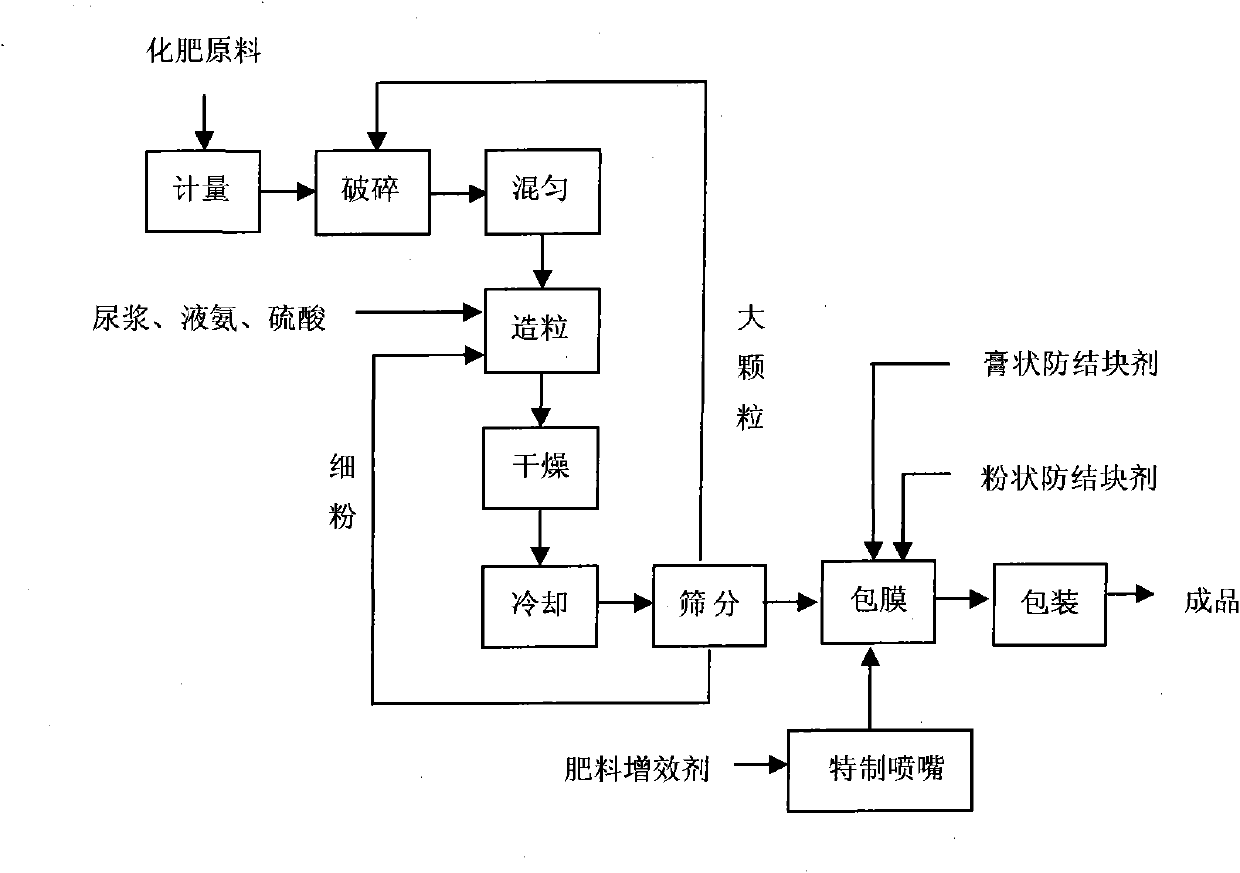

Image

Examples

Embodiment 1

[0032] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 51%, the specification is 17-17-17 chlorine-containing type synergistic compound fertilizer without filler, and the specific process operation steps are as follows:

[0033] (1) Measure 33.5 kilograms of potassium chloride (containing K 2 O-60%), 42.1 kg of monoammonium phosphate (containing N-10%, containing P 2 o 5 -48%), 13.0 kilograms of ammonium chloride (containing N-23.6%), 11.4 urea (containing N-46.2%), the above-mentioned raw materials are crushed and mixed uniformly, and the mixed material is sent into the drum granulator;

[0034] (2) Spray 159.1 kg of urine slurry, 26.1 kg of liquid ammonia, and 22.7 kg of dilute sulfuric acid per ton of mixed material in the granulator;

[0035] (3) One-stage drying, two-stage cooling and coarse and fine screening are adopted. After screening, the qualified particles enter the special coating machine, the large particles return to crushing, and the fine particles return to granulat...

Embodiment 2

[0039] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 48%, the specification is 25-13-10 chlorine-containing synergistic compound fertilizer without filler, and the specific process operation steps are as follows:

[0040] (1) Measure 21.1 kilograms of potassium chloride (containing K 2 O-60%), 37.4 kg of monoammonium phosphate (containing N-11%, containing P 2 o 5 -44%), 10.2 kilograms of ammonium chloride (containing N-23.6%), 31.3 kilograms of urea (containing N-46.2%), the above-mentioned raw materials are crushed and mixed uniformly to obtain a mixed material, which is sent into a drum granulator;

[0041] (2) Spray 217.6 kg of urine slurry, 28.5 kg of liquid ammonia, and 27.3 kg of dilute sulfuric acid per ton of mixed material in the granulator;

[0042] (3) One-stage drying, two-stage cooling and coarse and fine screening are adopted. After screening, the qualified particles enter the special coating machine, the large particles return to crushing, and the fine particles re...

Embodiment 3

[0046] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 45%, the specification is the synergistic compound fertilizer of 15-15-15 potassium sulfate type without filler, and concrete technological operation step is as follows:

[0047] (1) Measure 36.2 kilograms of potassium sulfate (containing K 2 O-50%), 41.5 kg of monoammonium phosphate (containing N-11%, containing P 2 o 5 -44%), 22.3 kilograms of ammonium sulfate (containing N-20.5%), the above-mentioned raw materials are crushed and uniformly mixed to obtain a mixed material, which is sent into a drum granulator;

[0048] (2) Spray 191.5 kg of urine slurry, 27.7 kg of liquid ammonia, and 23.4 kg of dilute sulfuric acid per ton of mixed material in the granulator;

[0049] (3) One-stage drying, two-stage cooling and coarse and fine screening are adopted. After screening, the qualified particles enter the special coating machine, the large particles return to crushing, and the fine particles return to granulation;

[0050] (4) Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com