Belt-type sintering machine material layer steam jetting humidifying device and humidifying method

A humidification device and sintering material technology, applied in the direction of combustion methods, lighting and heating equipment, combustion equipment, etc., can solve the problems of slowing down the vertical sintering speed and reducing the running speed of the sintering machine, so as to reduce the solid fuel consumption and sintered solids Effects such as fuel consumption and CO2 reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

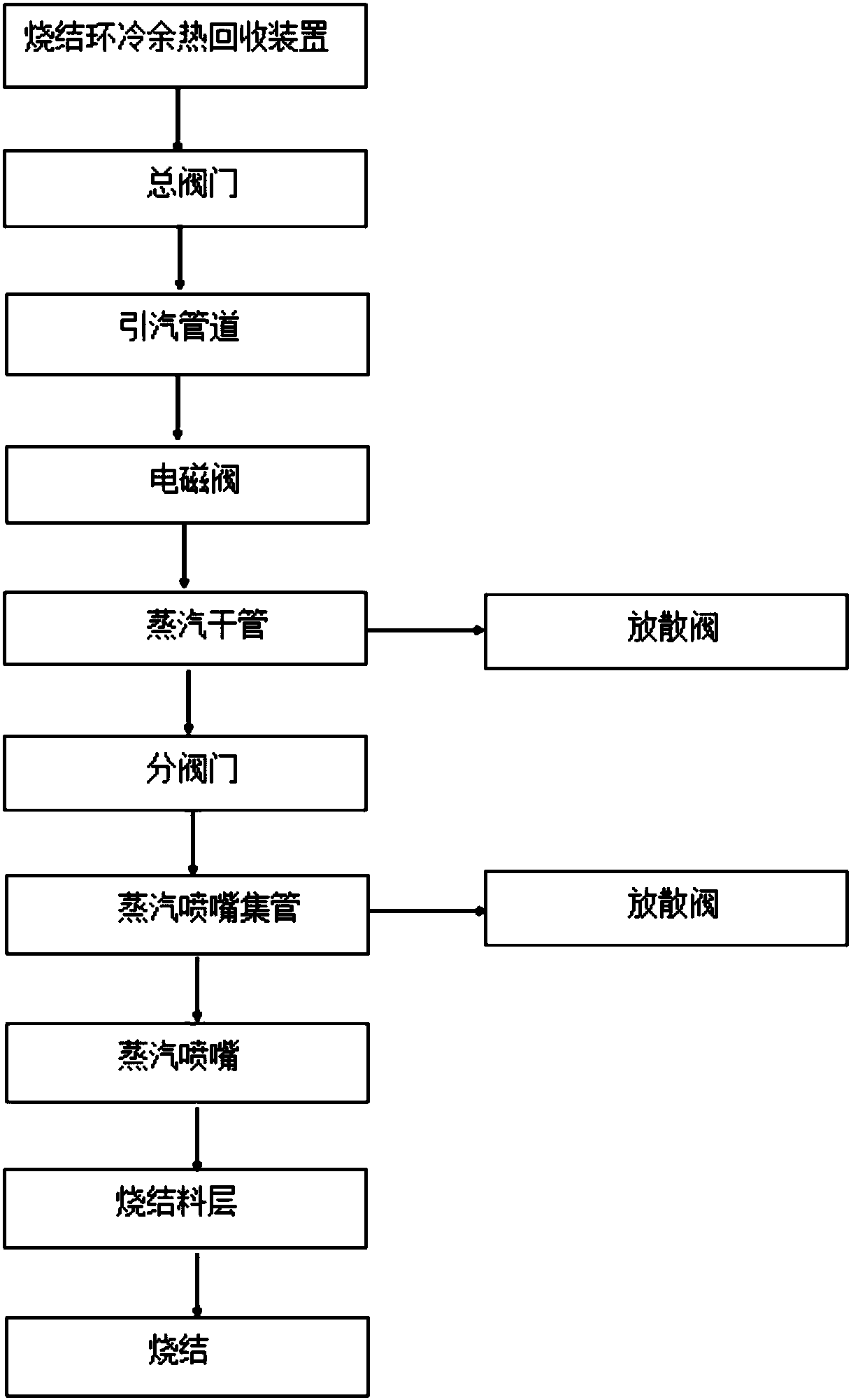

[0036] The steam is introduced from the sintering ring cold waste heat recovery system to the steam main pipe by the steam induction pipe. The steam working condition is 150°C and 0.3MPa. The steam injection nozzle header is set up at a distance of 1 / 3 from the sintering head, and the distance is 5 meters. Add a set of nozzle headers to a quarter of the distance from the tail of the sintering machine. The steam is sprayed vertically on the sintering material layer from the steam injection nozzle. Under the action of the exhaust fan, the steam participates in the sintering reaction, and the sintering area per square meter needs 3.4kg / h amount of steam.

Embodiment 2

[0038] The steam is introduced from the sintering ring cold waste heat recovery system to the steam main pipe by the steam induction pipe. The steam working condition is 150°C and 0.3MPa. The steam injection nozzle header is set up at a distance of 1 / 3 from the sintering head, and the distance is 5 meters. A set of nozzle headers is added to the quarter of the tail of the sintering machine, and the steam is sprayed vertically on the sintering material layer from the steam injection nozzle. h steam volume.

Embodiment 3

[0040] The steam is introduced from the sintering ring cold waste heat recovery system to the steam main pipe by the steam induction pipe. The steam working condition is 150°C and 0.3MPa. The steam injection nozzle header is set up at a distance of 1 / 3 from the sintering head, and the distance is 5 meters. A set of nozzle headers is added to the quarter of the tail of the sintering machine. The steam is sprayed vertically on the sintering material layer from the steam injection nozzle. Under the action of the exhaust fan, the water vapor participates in the sintering reaction, and each square sintering area needs 3.8kg / h steam volume.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com