Novel technics of rough-flotation high concentration high-efficient flotation

A high-concentration, new process technology, applied in flotation, solid separation and other directions, can solve the problem of no more research on the separation of sulfide ore and oxide ore, so as to improve flotation efficiency, ensure quality, and improve operation recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

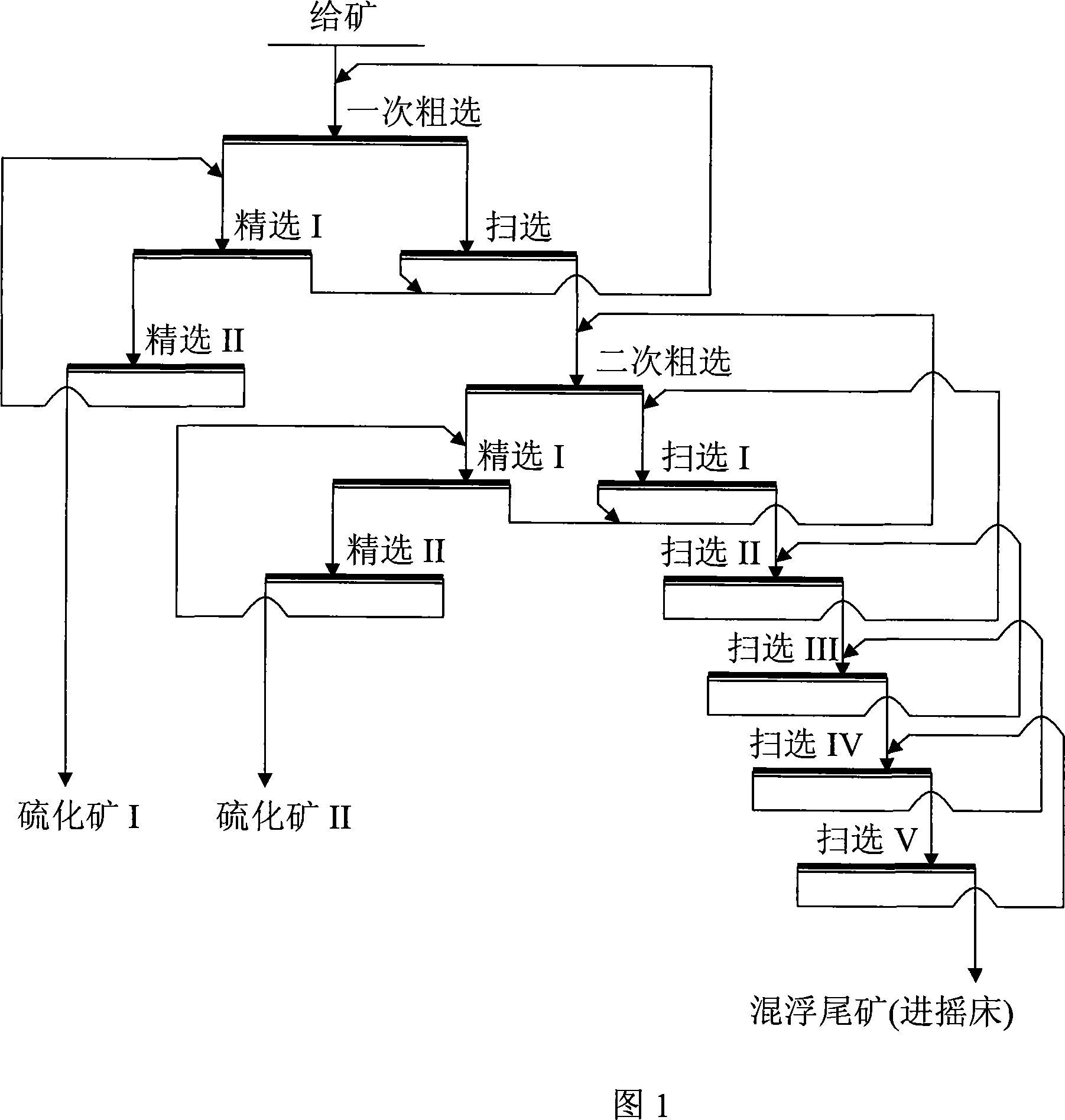

Image

Examples

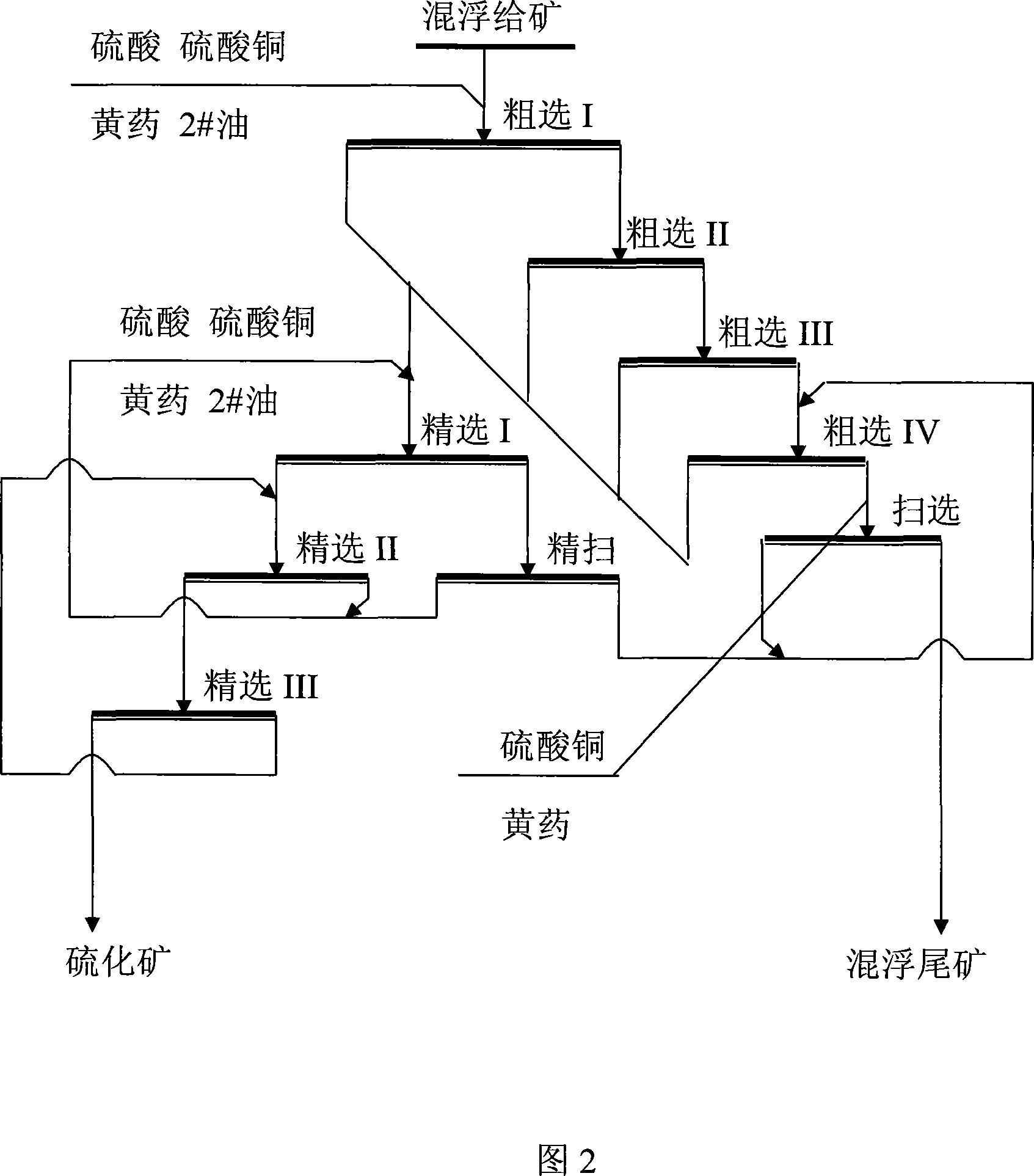

Embodiment 1

[0039] Mixed flotation feed ore (pulp with a concentration of 45-60%) enters flotation and undergoes four times of roughing, and separates the previous flotation tailings separately, without forming middle ore, and the flotation foam concentrate of four times of roughing Concentrate on selection, in these four rough selections, gradually strengthen the flotation intensity (weak selection with good buoyancy, strong selection with poor buoyancy), increase the dosage (such as xanthate and copper sulfate, concentration 1-2% ) and prolong the flotation time (2 to 5 minutes), that is to say, dosing in stages is intensified sequentially, the time of the four roughings is 2 minutes, 3 minutes, 4 minutes, and 5 minutes in turn, and the amount of medicine (such as xanthate and copper sulfate, etc.) ) and dosing sequence (sulfuric acid→copper sulfate→xanthate→2 # Oil, sulfuric acid, copper sulfate, and xanthate each have a concentration of 1-2%, 2 # The oil is added drop by drop accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com