Preparation process for organic-inorganic compound fertilizer

A compound fertilizer and preparation process technology, applied in fertilizer forms, fertilizer mixtures, fertilization devices, etc., can solve problems such as accumulation of harmful substances that increase the degree of soil compaction, decline in the quality of agricultural products, and large use of chemical fertilizers. The effect of improving utilization and meeting growth needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

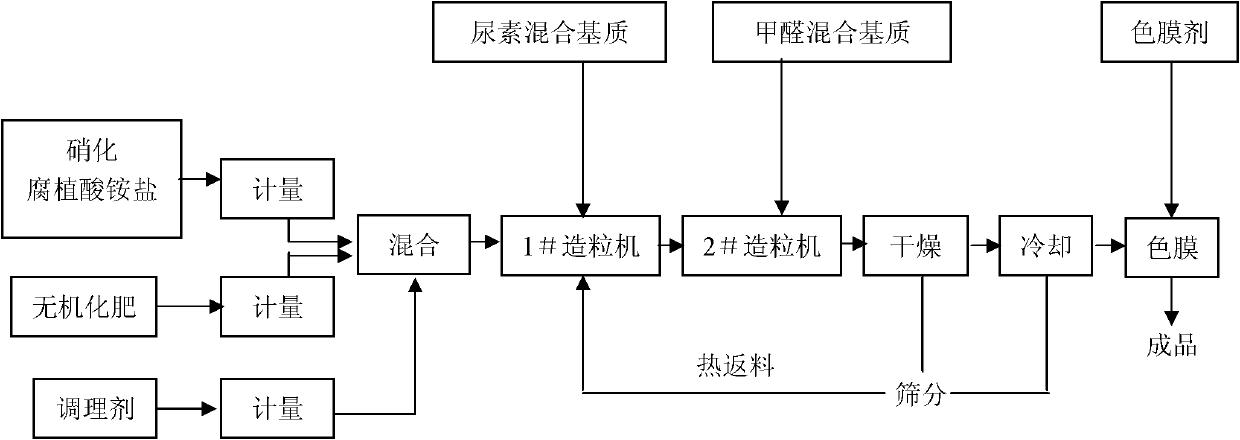

[0064] The preparation technology of organic-inorganic compound fertilizer is characterized in that it comprises the following steps:

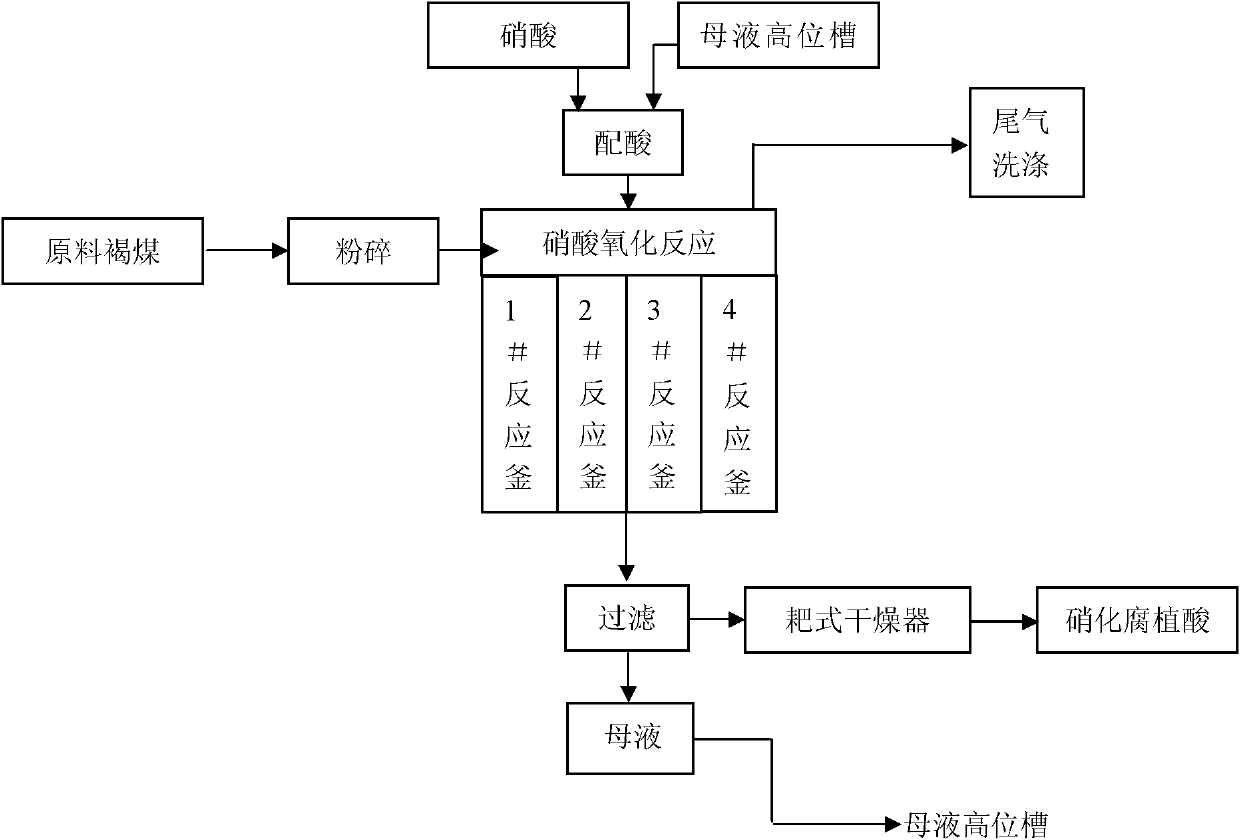

[0065] 1) Mix nitric acid with a volume concentration of 28% and lignite at a ratio of 1:0.3 by mass, then fully stir, and react at 80° C. for 36 hours; after the reaction is completed, filter and separate to obtain an organic precipitate containing lignite nitrated humic acid;

[0066] 2) Add 2.5 times the mass of ammonium bicarbonate to the organic matter precipitate containing lignite nitrating humic acid, react at 50°C for 10 hours, and then dry at room temperature, lignite nitrating humic acid reacts with ammonium bicarbonate or ammonia water to form lignite nitrating humic acid ammonium salt ;

[0067] 3) by lignite nitration humic acid ammonium salt: the ratio of mass ratio=1:2 of inorganic fertilizer, lignite nitration humic acid ammonium salt 120~180kg, potassium chloride 90~160kg and ammonium dihydrogen phosphate 100~200kg are mixed,...

Embodiment 2

[0073] The preparation technology of organic-inorganic compound fertilizer is characterized in that it comprises the following steps:

[0074] 1) Mix nitric acid with a volume concentration of 25% and lignite at a mass ratio of 1:0.5, then fully stir, and react at 90°C for 24 hours; after the reaction is completed, filter and separate to obtain an organic precipitate containing lignite nitrated humic acid;

[0075] 2) Add ammonia water (volume concentration 28%) of 3 times its mass to the organic matter precipitation containing lignite nitrating humic acid, react at 55°C for 8h, and then dry at room temperature, lignite nitrating humic acid reacts with ammonium bicarbonate or ammonia water to form lignite Ammonium humic acid salt;

[0076] 3) Mix it according to the mass ratio of lignite nitrated humic acid ammonium salt: inorganic fertilizer = 1: 3, mix lignite nitrated humic acid ammonium salt 150-190kg, potassium chloride 190-250kg and ammonium dihydrogen phosphate 180-260k...

Embodiment 3

[0082] The preparation technology of organic-inorganic compound fertilizer is characterized in that it comprises the following steps:

[0083] 1) Mix nitric acid with a volume concentration of 25% and lignite in a mass ratio of 1:0.4, then fully stir, and react for 30 hours at 85° C.; filter and separate after the reaction is completed, and obtain an organic precipitate containing lignite nitrated humic acid;

[0084] 2) adding ammonia water of 3.5 times the mass to the organic matter precipitation containing lignite nitrating humic acid, reacting at 55° C. for 8 hours, and then drying at room temperature, lignite nitrating humic acid reacts with ammonium bicarbonate or ammonia water to generate lignite nitrating humic acid ammonium salt;

[0085] 3) According to the mass ratio of lignite nitrated humic acid ammonium salt: inorganic fertilizer = 1: 2.5, 150-190 kg of lignite nitrated humic acid ammonium salt, 180-260 kg of diammonium hydrogen phosphate, 20-30 kg of bentonite, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com