Circulating fluidized bed boiler applicable to garbage incineration

A circulating fluidized bed and waste incineration technology, which is applied in incinerators, fluidized bed combustion equipment, and molten fuels, etc., can solve the problem of low combustion temperature, unstable combustion and low calorific value of waste in fluidized bed incinerators. and other problems, to achieve the effect of solving high temperature corrosion and coking of flue gas, improving combustion efficiency and stability, and reducing NOx generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

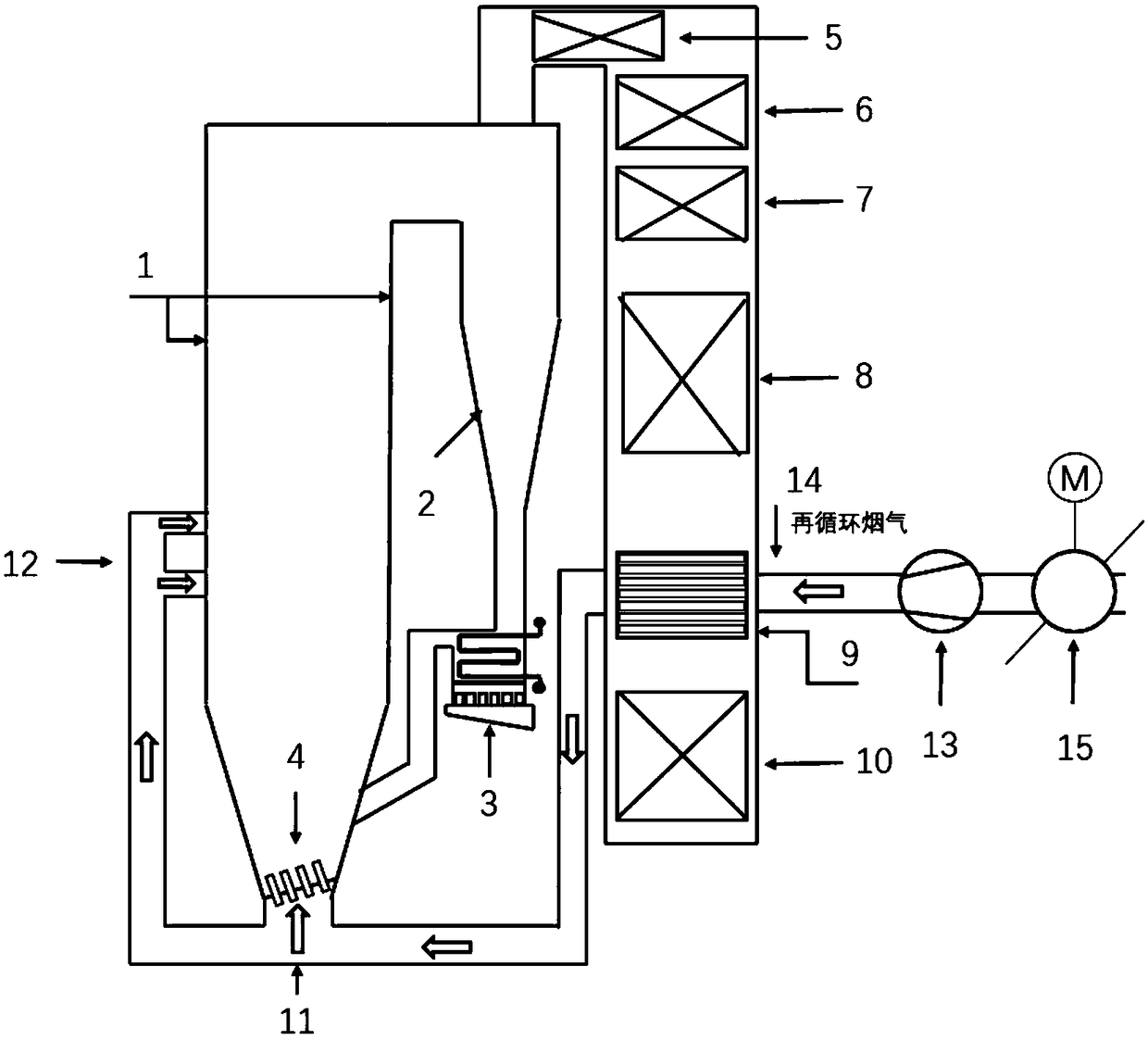

[0028] Example 1 such as figure 1 As shown, a circulating fluidized bed boiler suitable for waste incineration, including 1. adiabatic furnace, 2. high-efficiency cyclone separator, 3-external bed heat exchanger (high temperature superheater), 4-inclined air distribution plate, 5 -evaporation tube bundle, 6-water cooling tube bundle, 7-low temperature superheater, 8-coal economizer, 9-recirculation flue gas heat exchanger, 10-air preheater, 11-primary air pipe, 12-secondary air pipe. 13-recirculation flue gas booster fan, 14-recirculation flue gas pipe, 15-valve. Garbage fuel is burned in the furnace. Since the heating surface of the furnace is covered by castables to form an adiabatic furnace 1, the furnace can stably reach a combustion temperature above 850°C. Garbage is burned in the adiabatic furnace 1 to produce a large amount of high-temperature flue gas and fly ash. The high-temperature flue gas carries unburned carbon particles and recycled materials in the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com