Hot blast stove burning method

A technology of hot blast stove and fan, which is applied in the field of hot blast stove firing, and can solve problems such as low air temperature, complicated equipment, and unrealistic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

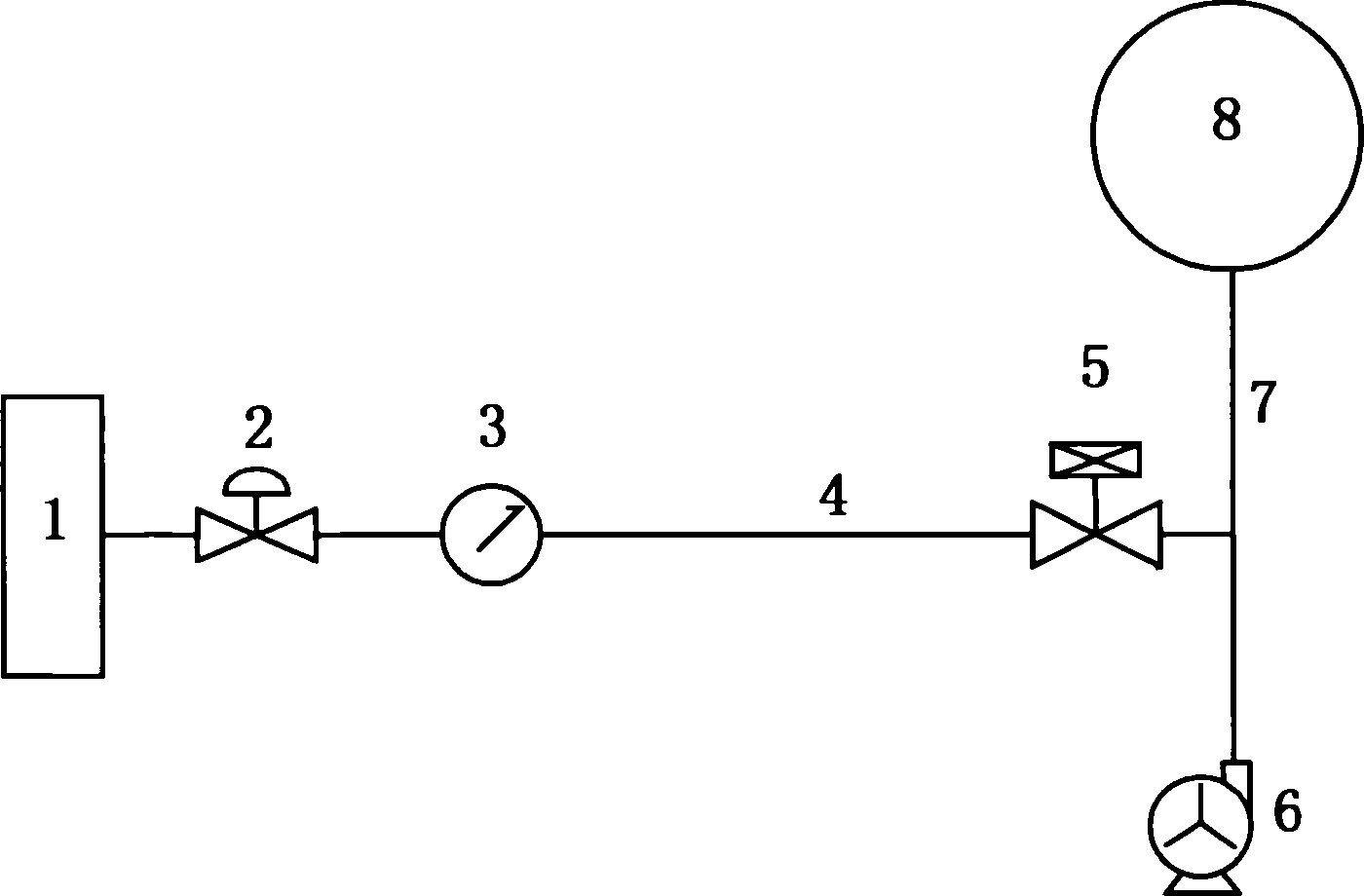

[0011] The present invention will be further described below in conjunction with the accompanying drawings. When the hot blast stove (8) was in the furnace state, the safety cut-off valve (5) was opened by the computer control system, and then according to the display of the flowmeter (3), the opening degree of the electric film regulating valve (2) was determined. When the hot-blast stove (8) stopped burning the furnace, the electric film regulating valve (2) was closed by the computer control system. When the oxygen pressure is lower than 300kPa, the hot blast furnace operating system will alarm; when the oxygen pressure is lower than 250kPa, the safety shut-off valve (5) will be automatically closed; The safety cut-off valve (5) is automatically closed.

[0012] From the oxygen bag in front of the blast furnace, use DN50 steel pipe to connect oxygen, directly add it to the main combustion air pipe of the hot blast stove, and install an electric film regulating valve and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com