A control method of blast furnace blast system with oxygen enrichment before the machine

A blast furnace blasting and control method technology, applied in blast furnace, pump control, blast furnace details, etc., can solve problems such as waste, long cycle, and reduced operating efficiency of the blower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

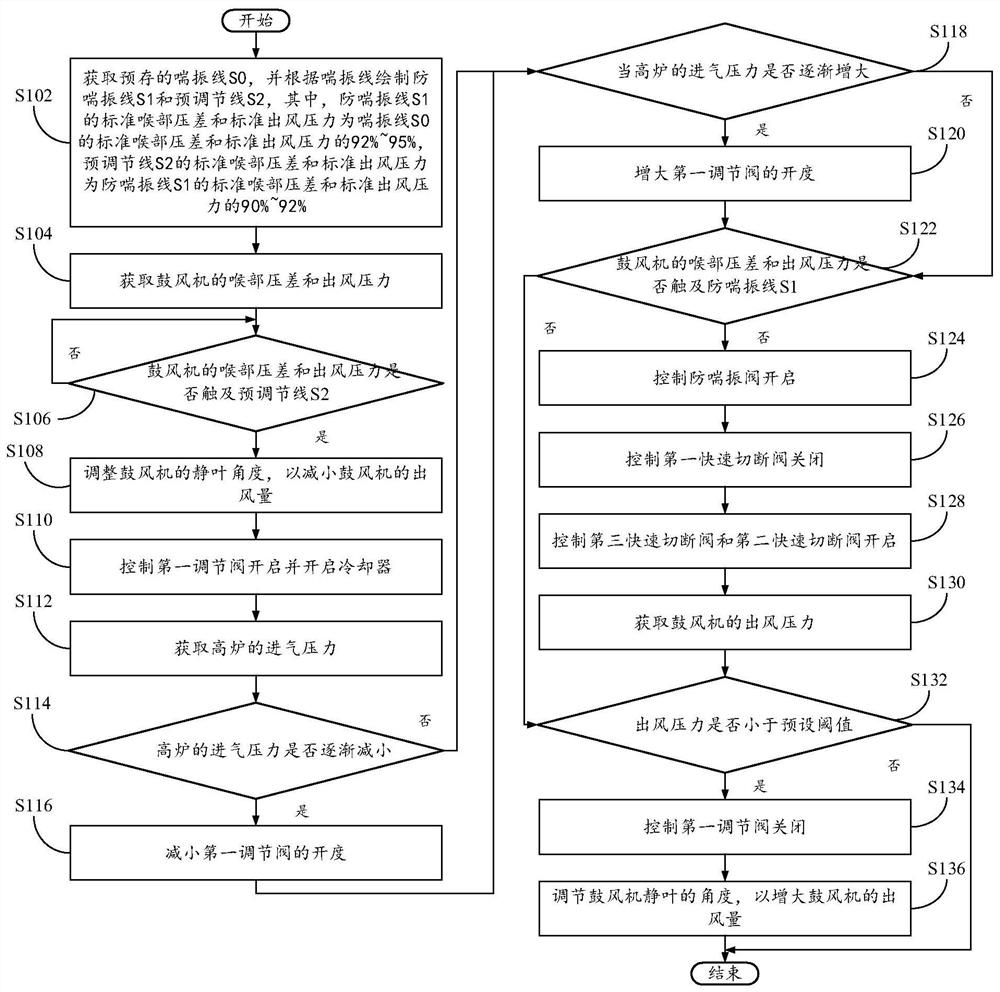

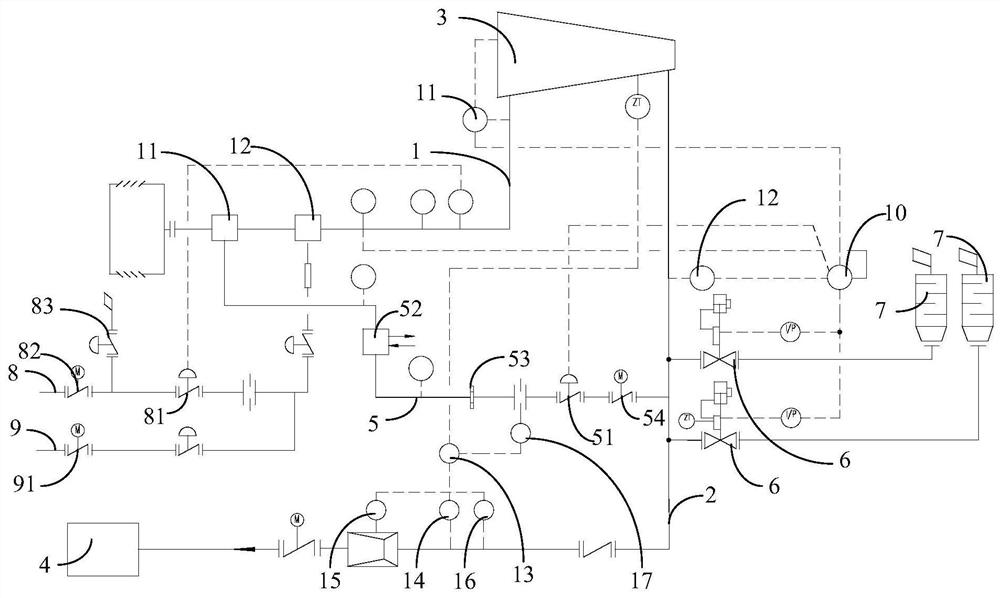

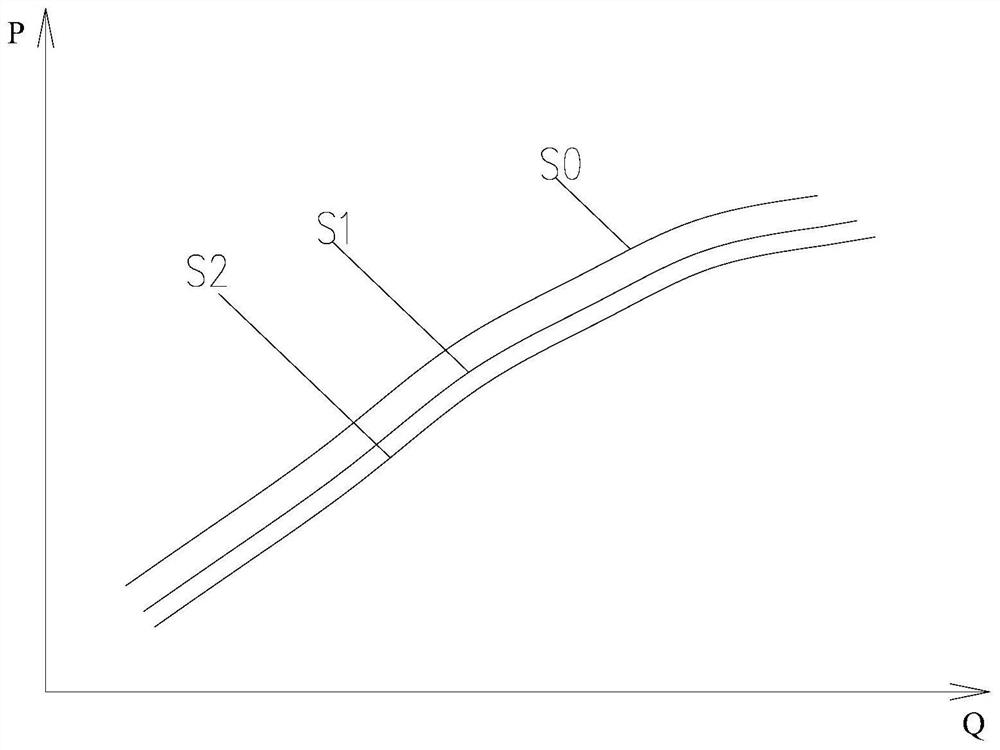

[0050] Such as Figure 1 to Figure 3 As shown, the specific embodiment of the present invention provides a control method of the oxygen-enriched blast furnace blast system in front of the machine. The blower 3 of the oxygen-enriched blast furnace blast system in front of the machine is connected to the inlet pipeline 1 and the outlet pipeline 2, and the gas passes through the inlet pipeline. The gas pipeline 1 is sucked into the blower 3, and after being pressurized by the blower 3, it is sent into the blast furnace 4 through the gas outlet pipeline 2. The gas pipeline 1 is connected, and the recirculation pipeline 5 is connected in series with a first regulating valve 51 . The recirculation line 5 is also provided with a cooler 52 . The oxygen-enriched blast furnace blast system in front of the machine also includes an anti-surge valve 6 connected with the outlet pipeline 2, and an oxygen pipeline 8, which is connected in series with the second regulating valve 81 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com