Novel combined brick structure of self-locking sealed blast furnace warm air duct intersection

A hot air duct, sealed technology, applied in blast furnaces, blast furnace details, furnace types, etc., can solve the problems of limiting hot air temperature, oxygen-enriched rate pulverized coal injection, heat energy loss production output, red burning at the three forks, etc. Achieve unique and practical ideas, reduce heat loss and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

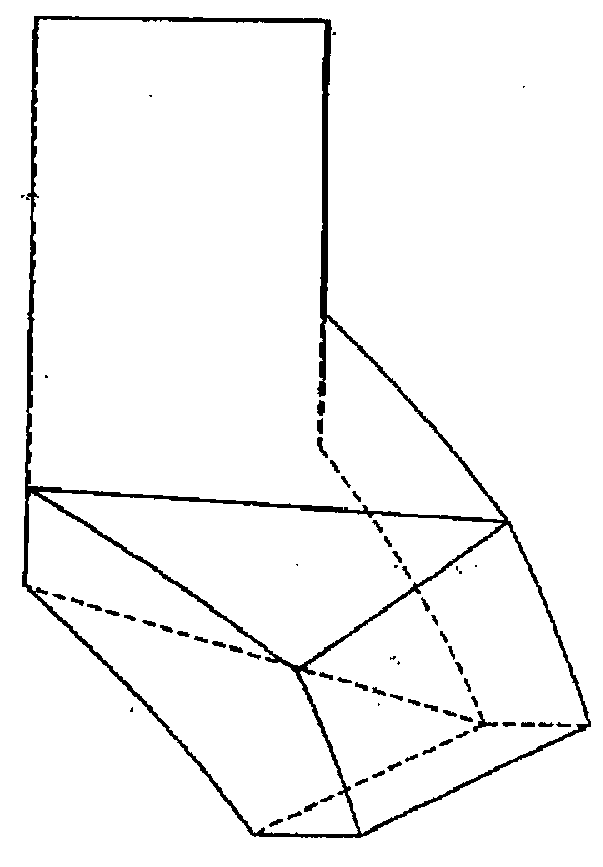

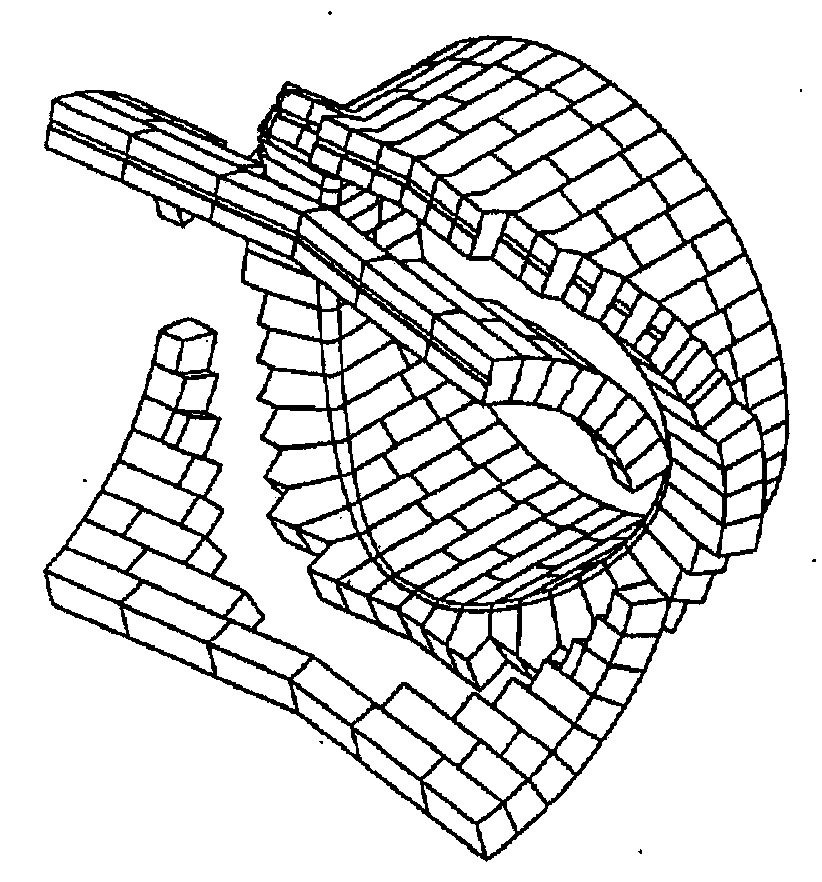

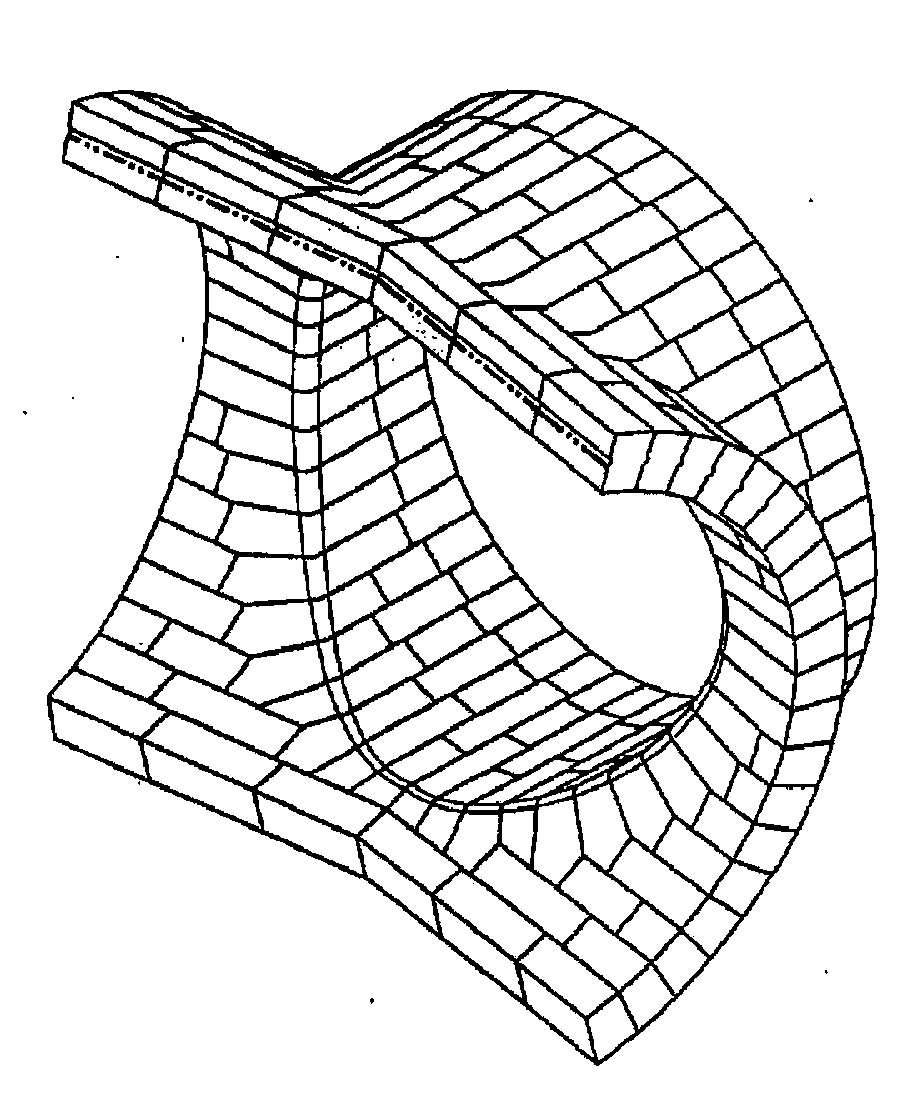

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , 3, and 4 show:

[0047] A new type of composite brick structure with self-locking and sealed blast furnace hot blast pipe three-fork, which consists of self-locking refractory bricks with flat ends at both ends and self-locking refractory bricks with flat ends at one end and pointed ends at the other end to form blast furnace hot air. A new ring-shaped combined brick structure at the junction of the main pipe and the surrounding pipe in the pipeline, so as to eliminate the annular fracture crack at the junction of the main pipe and the surrounding pipe junction in the blast furnace hot blast pipeline and many triangular fractures along the annular fracture;

[0048] The self-locking sealed blast furnace hot air pipeline is a new composite brick structure with three forks, and the bending angles of the self-locking refractory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com