Full-vacuum pump pool

A full-vacuum and vacuum technology, used in pumps, pump components, variable-capacity pump components, etc., can solve the problems of poor vacuum insulation performance, lack of scientific rationality, and lack of beauty and elegance, and achieve good vacuum insulation performance and scientific and rational design. , the overall beautiful and generous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

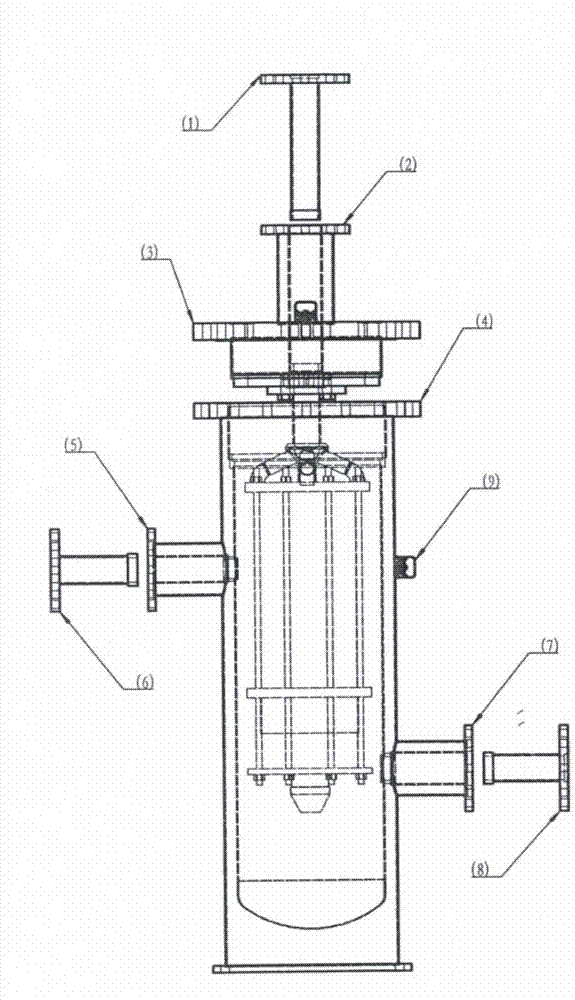

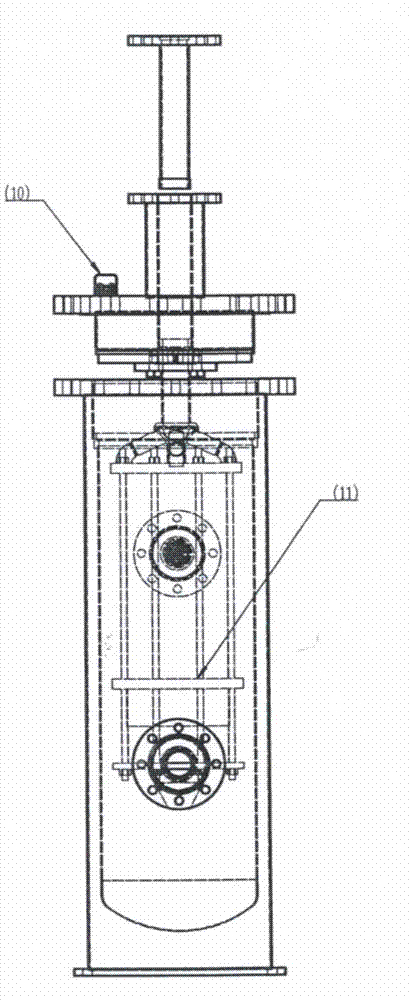

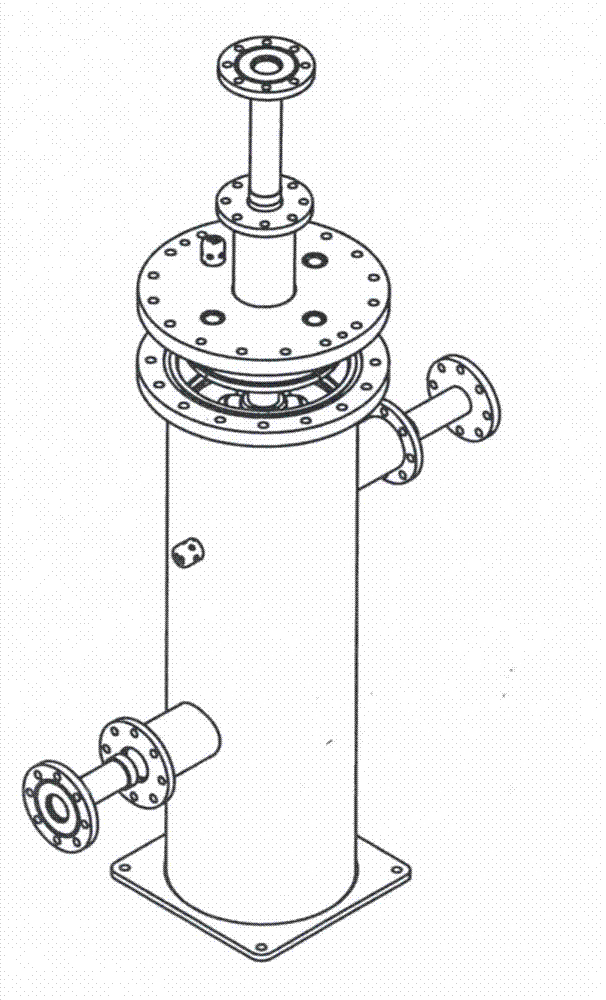

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , as shown in 3:

[0032] A full vacuum pump tank, consisting of a vacuum male flange 1 at the liquid outlet, a female vacuum flange at the liquid outlet 2, a large vacuum flange upper cover 3, a vacuum tank body 4 for the pump pool, a vacuum female flange 5 at the air return port, and a vacuum male flange at the air return port Lan 6, the vacuum female flange of the liquid inlet 7, the vacuum male flange of the liquid inlet 8, the vacuum seal of the pump pool tank 9, the vacuum seal of the large flange upper cover 10, and the cryogenic submersible pump 11;

[0033] In the full vacuum pump pool, the flange plate of the vacuum male flange 1 at the liquid outlet and the flange plate of the vacuum female flange 2 at the liquid outlet, the flange plate of the vacuum female flange 2 at the liquid outlet and the upper cover of the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com