Blast furnace hot-blast stove orifice combination brick structure

A hot blast stove and combined brick technology, applied in blast furnaces, brick blast furnaces, blast furnace details, etc., can solve the problems of lack of scientific and reasonable structure design, affecting normal production, heat energy loss, etc. The effect of popularizing application and increasing the temperature of hot air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

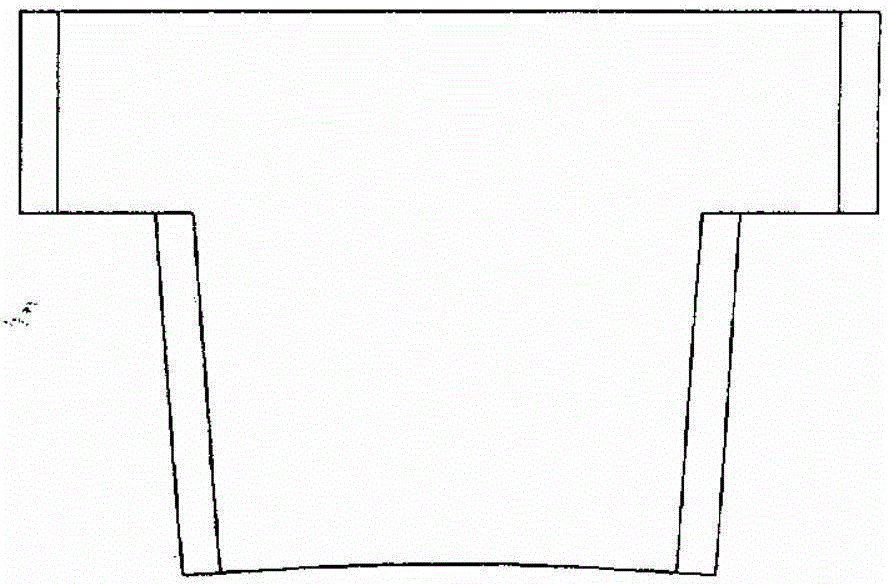

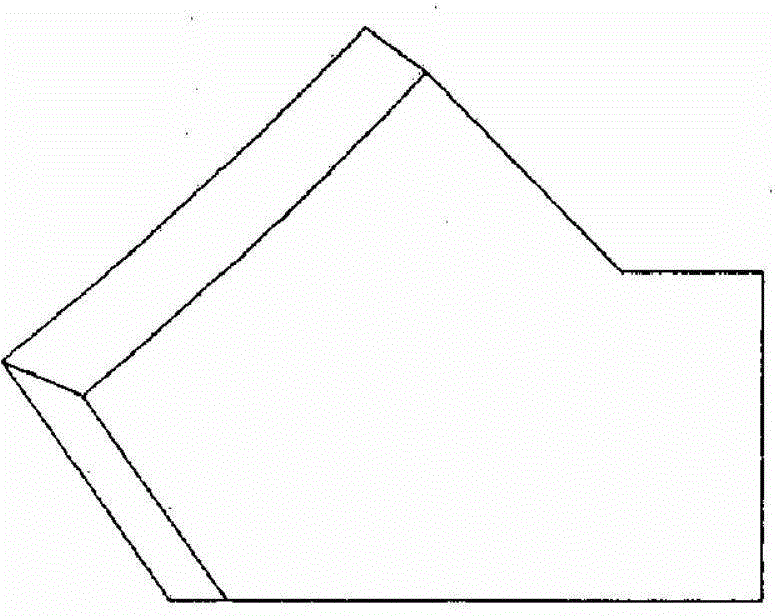

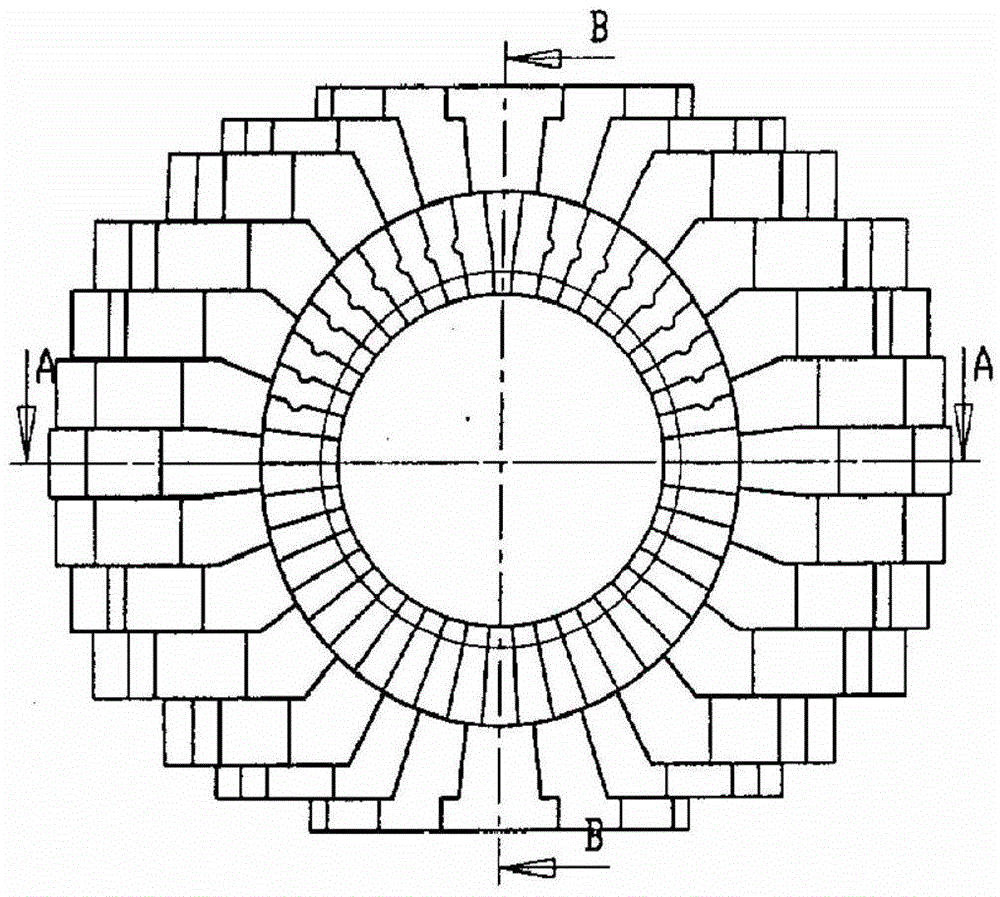

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , 3, 4, 5, 6, and 7:

[0053] A combined brick structure for blast furnace hot blast furnace nozzles. A T-shaped refractory brick 121 is used at the top and bottom of the ring, and L-shaped refractory bricks 122 are used on both sides of the ring to form an outer ring 1 with an elliptical inner diameter. The outer ring 2 is composed of the inner ring 3 and the adjacent inner ring 4 which are built with sealed refractory bricks to form an oval outer diameter. The outer ring 1 and the adjacent outer ring 2, the inner ring 3 and the adjacent inner ring 4 The outer ring 1 and the elliptical ring adjacent to the outer ring 2 are fixedly connected by refractory cement in the state of being attached to each other, and the outer ring 1 and the inner ring 2 are fixedly connected by refractory cement in the state of the inner ring 3 and ...

specific Embodiment approach 2

[0064] Implementation is carried out according to specific embodiment 1, except that: the ellipse is replaced by a circle; the expected good effect is obtained.

specific Embodiment approach 3

[0065] Carry out according to specific embodiment 1, just: replace described outer ring 1 and adjacent outer ring 2 with single-layer outer ring and carry out implementation; Replace described inner ring 3 and adjacent inner ring 4 with single-layer inner ring and carry out Implementation; have achieved the expected good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com