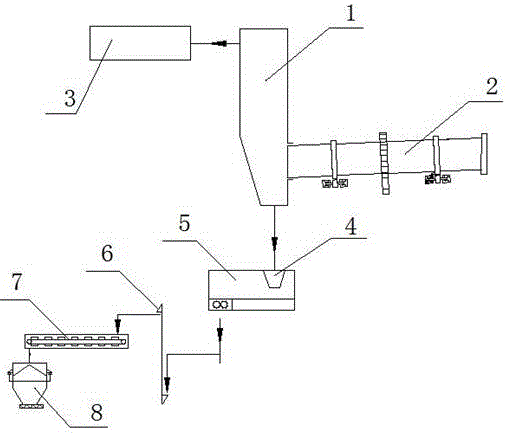

Dangerous waste incineration system

A hazardous waste and air cooler technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of high water content in ash, high landfill cost, large water consumption, etc., achieve small ash volume, The effect of saving water resources and reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

[0014] see figure 1 , the kiln tail of the rotary kiln 2 is connected to the slag inlet of the second combustion chamber 1, the flue gas outlet above the second combustion chamber 1 is connected to the flue gas treatment device 3, and the slag outlet below the second combustion chamber 1 is connected to the grate air cooler The slag inlet of the grate air cooler 5 is connected to the slag inlet, and a stirring device 4 is installed below the slag inlet of the grate air cooler 5. A heat insulation layer is installed on the wall plate in the grate air cooler 5. The outlet of the grate air cooler 5 The slag outlet is connected to the feeding end of the conveying equipment 7 through the bucket elevator 6 , and the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com